Method for measuring pressure and non-contact displacement by using flexible pressure sensitive coil

A non-contact and flexible technology, applied in the field of sensors, can solve problems such as large repeatability errors, achieve stable response and improve repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0016] (1) Before calibration, apply a pressure of 3MPa to the flexible pressure-sensitive coil with a range of 1MPa and maintain it for 2 hours before unloading to 0MPa. Then, repeat the following loading and unloading cycle for the flexible pressure-sensitive coil 30 times: from 0MPa to 1MPa Then unload to 0MPa; connect the two ends of the flexible pressure-sensitive coil to the output terminal and the reverse terminal of the operational amplifier, connect the output terminal of the operational amplifier to the input terminal of the analog-to-digital conversion module, and connect the output of the analog-to-digital conversion module to the flexible pressure-sensitive The digital quantity corresponding to the coil impedance is connected to the microprocessor;

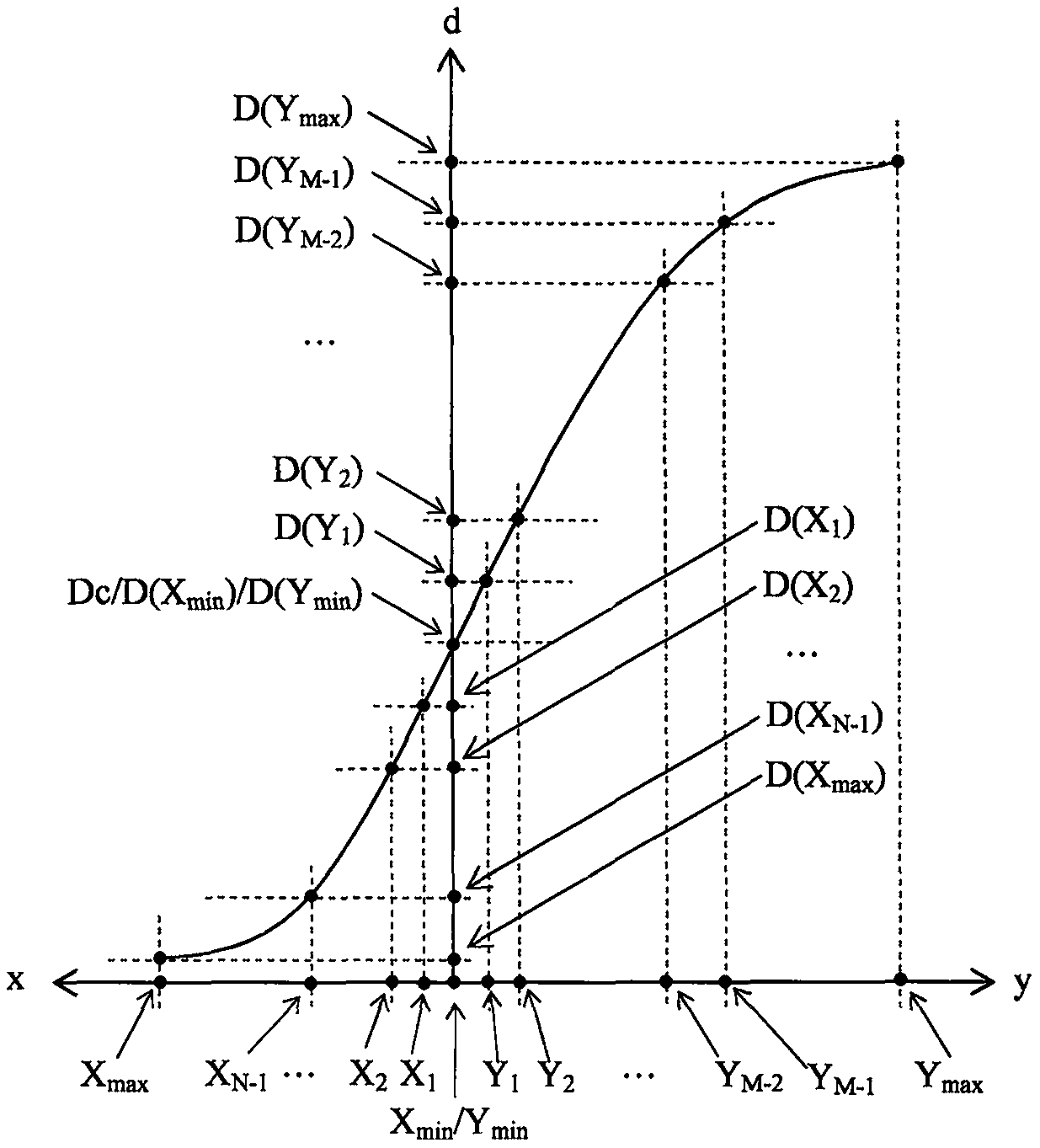

[0017](2), in the calibration stage, obtain the impedance value at the transition point of the flexible pressure sensitive coil from the non-contact stage to the contact stage as the critical impedance, and then obtain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com