Method for judging loading phase of flexible pressure sensitive coil

A coil and flexible technology, applied in the field of sensors, can solve the problems of the adverse effects of pressure and non-contact displacement measurement, the drift of critical impedance, and the difficulty of flexible pressure-sensitive coils in the load stage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

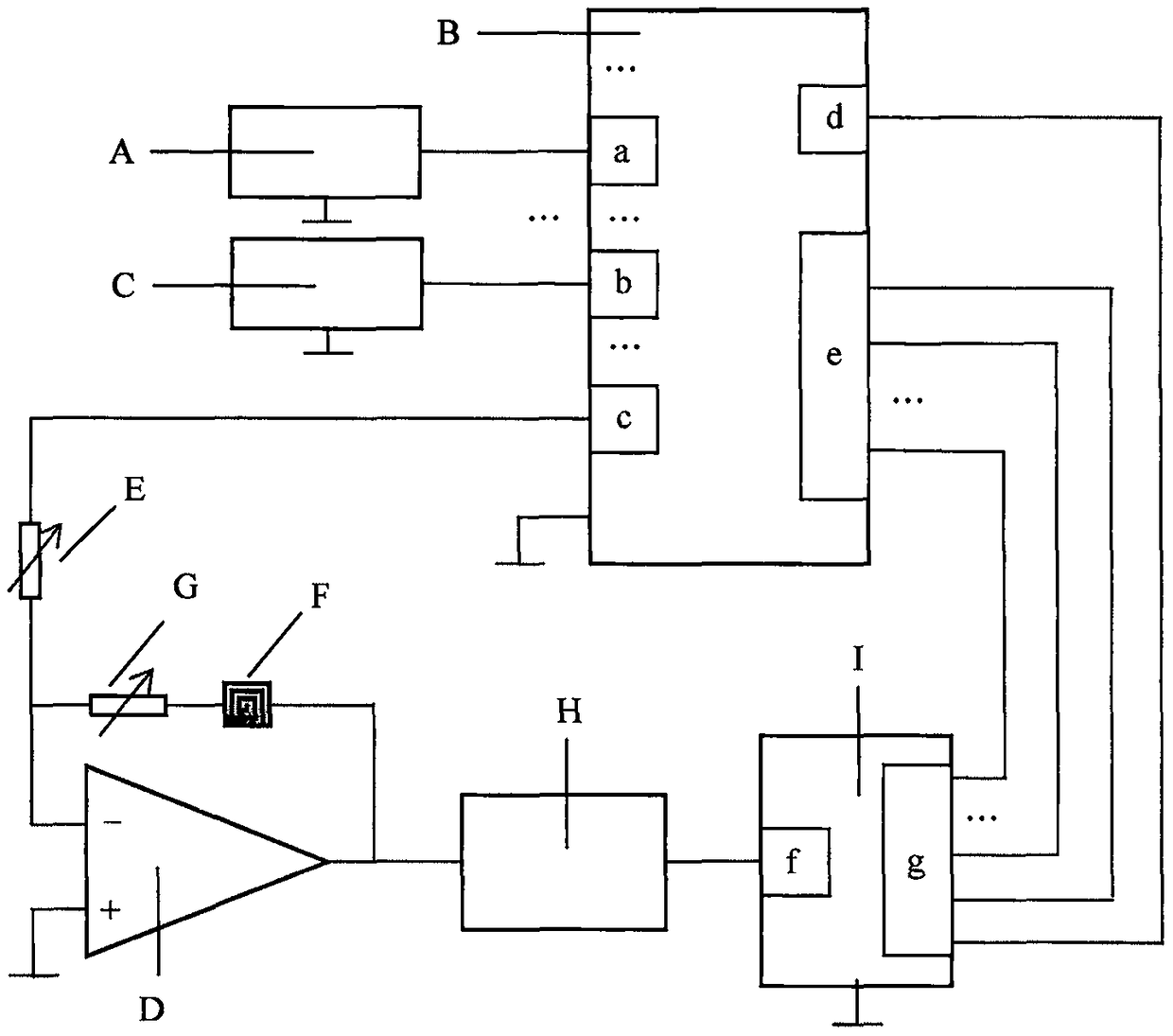

[0014] Connect the AC signal source to the first input port (pin 13) of the multiplexer MAX4617, and connect the DC signal source to the second input port (pin 14) of the multiplexer MAX4617 ); connect the output port (the third pin) of the multiplexer MAX4617 to the inverting terminal of the operational amplifier through an adjustable impedance; connect the flexible pressure-sensitive coil and another adjustable impedance in series and place it in the operation Between the inverting terminal and the output terminal of the amplifier; convert the output signal of the operational amplifier into a digital signal through an analog-to-digital converter; input the digital signal output from the analog-to-digital converter to the microprocessor; connect the output signal line of the microprocessor Connected to the enable terminal (pin No. 6) and logic control terminal (pin No. 9, 10 and 11) of the multiplexer to control the AC signal source and the DC signal source to pass through the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com