Direct contact phase-changing heat storage device

A heat storage device, phase change heat storage technology, applied in heat storage equipment, indirect heat exchangers, heat exchanger types, etc. Problems such as small contact area, affecting heat storage or heat release performance, etc., achieve the effect of improving heat storage and heat release performance, simple and reliable installation and use, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

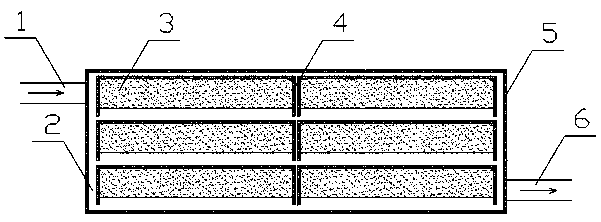

[0011] The structure diagram of the present invention is as figure 1 As shown, the direct contact phase-change heat storage device of the present invention includes a heat-carrying fluid inlet 1, a heat-carrying fluid flow channel 2, a phase-change heat storage material 3, a fixed frame 4 of a heat-change material, and a heat storage device container shell 5. Heat-carrying fluid outlet 7, in which several phase-change heat storage material fixing frames 4 are installed in the heat storage device container shell 5, between adjacent phase-change heat storage material fixing frames 4 and phase change heat storage material fixing frames 4 The gap between the heat storage device container shell 5 is the heat carrier fluid flow channel 2, the phase change heat storage material 3 is installed in the phase change heat storage material fixed frame 4, and one end of the heat storage device container shell 5 is provided with a heat carrier The fluid inlet 1 and the other end of the heat ...

Embodiment 2

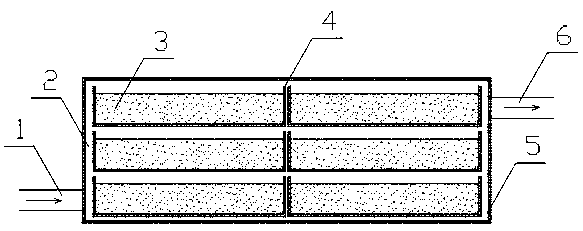

[0022] The structure diagram of the present invention is as figure 2 As shown, the difference between the present invention and Embodiment 1 is that the density of the phase-change heat storage material 3 is higher than that of the heat-carrying fluid, and the opening direction of the heat storage material fixing frame 4 is upward, and the phase-change heat storage material 3 is subjected to gravity, and there is a direction to force to move. Under the constraint of the closed end of the heat storage material fixed frame 4, the phase change heat storage material 3 is stored in the heat storage material fixed frame 4, such as figure 2 shown.

[0023] In the present invention, when heat storage is required, the heat-carrying fluid inlet 1 flows into the high-temperature heat-carrying fluid, and in the process of passing through the heat-carrying fluid channel 2, the heat is transferred to the phase-change heat storage material 3 and the heat storage material fixed frame 4, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com