Acid-method regenerative organic phase process in vanadium extraction cycle

An organic phase and extraction technology, applied in the field of acid regeneration organic phase process, can solve the problems of increased cost, required equipment, large organic phase loss, etc., and achieves the effects of cost saving, cost reduction and consumption saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

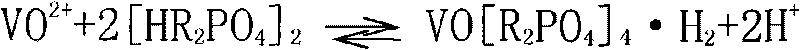

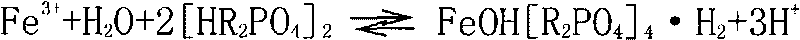

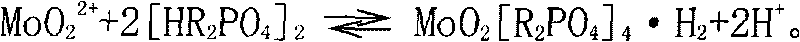

[0028] A process for regenerating the organic phase by acid method in the extraction cycle of vanadium extraction. In the extraction cycle, sulfuric acid solution with a concentration of 250-300g / l is used as the regeneration agent for the regeneration of the solvent-extracted lean organic phase; the flow rate of the lean organic phase and the regeneration agent The ratio is 10 to 15:1. When the impurity concentration of the lean organic phase is high, increase the flow rate of the regenerant, usually 10:1 is sufficient, otherwise it is better to be as small as 15:1; the lean organic phase and the regenerated water phase are in a mixed system The volume ratio (contact ratio) is preferably 1.2 to 1.5:1. When the contact ratio is less than 1.2:1, the water phase will appear as a continuous phase, which is not conducive to phase separation, and will reduce the time required for regeneration. Affect the regeneration efficiency; when the contact ratio is greater than 1.5:1, the rege...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com