Mixer-settler

A technology of mixing and settling tanks and settling tanks, which is applied in the field of liquid-liquid extraction, can solve the problems of low mass transfer efficiency and achieve the effect of improving mass transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] This embodiment provides a mixing and clarification tank, comprising: at least one clarification tank, the clarification tank includes: a mixing chamber, a clarification chamber, and a separation chamber arranged and communicated in sequence, and the clarification tank also includes: a submerged chamber arranged below the mixing chamber The separation chamber includes: a heavy phase chamber and a light phase chamber. The light phase and heavy phase enter the mixing chamber to be mixed into a mixed phase, and then sent to the clarification chamber. The clarification chamber is used to separate the mixed phase into a light phase and a heavy phase. and sent to the light phase chamber and the heavy phase chamber respectively in the separation chamber, and flow out of the clarification tank from the light phase chamber and the heavy phase chamber; The phase or light phase flows into the return chamber, one end of the return pipe is connected to the submerged chamber, and the ...

Embodiment 2

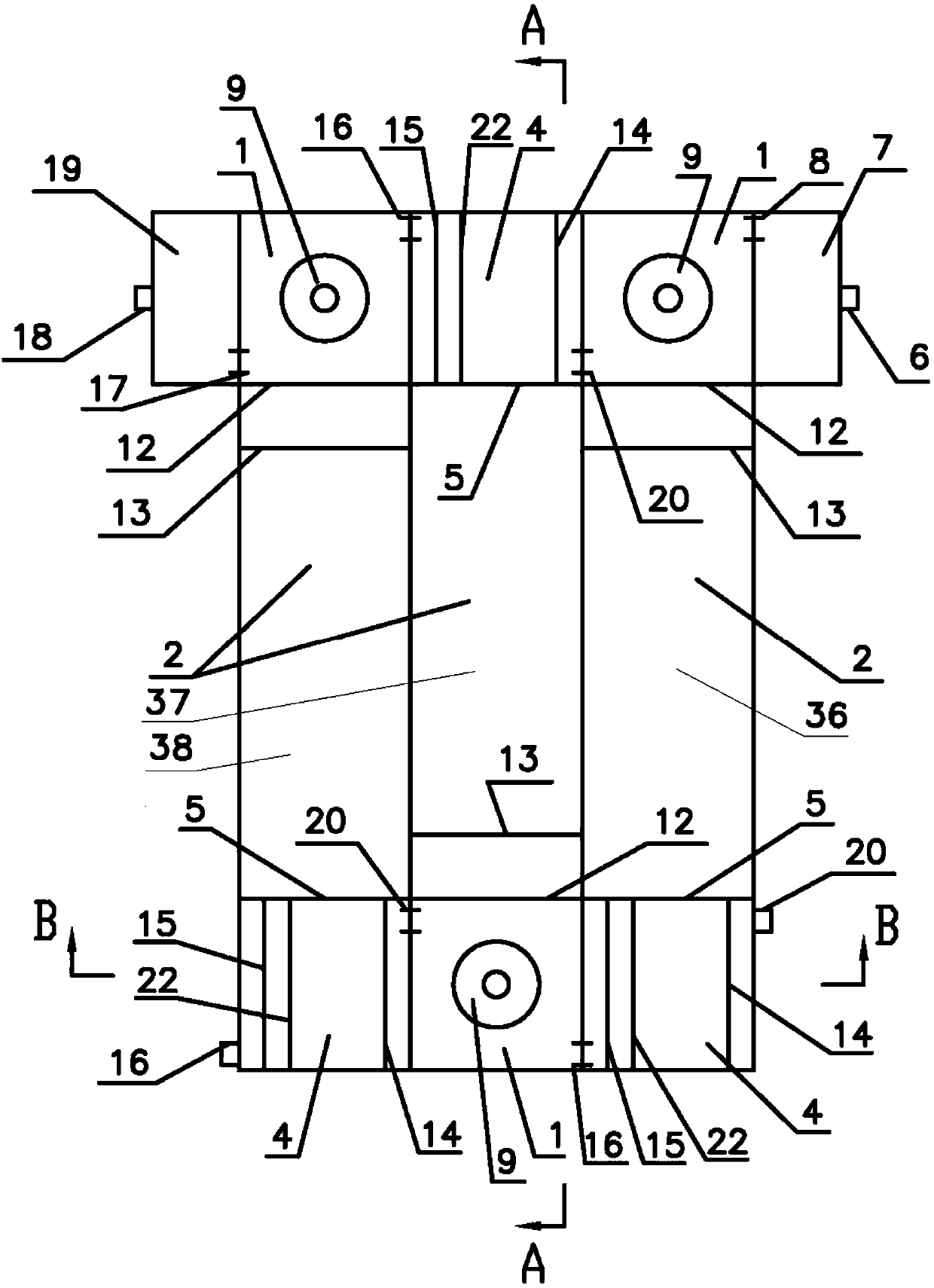

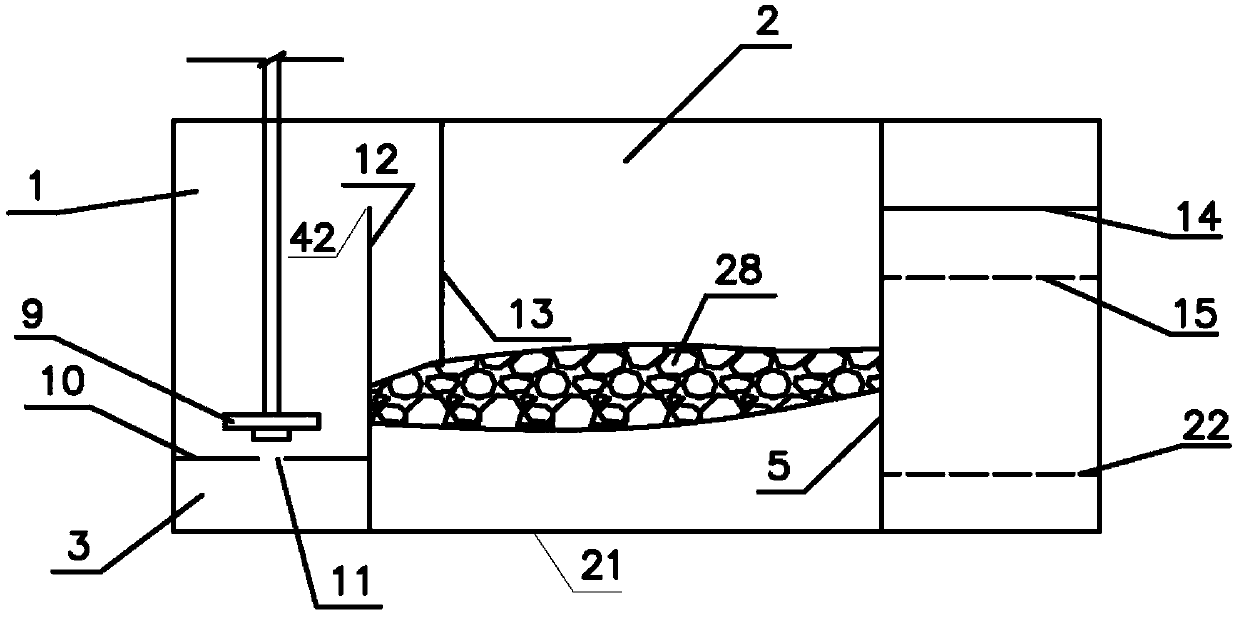

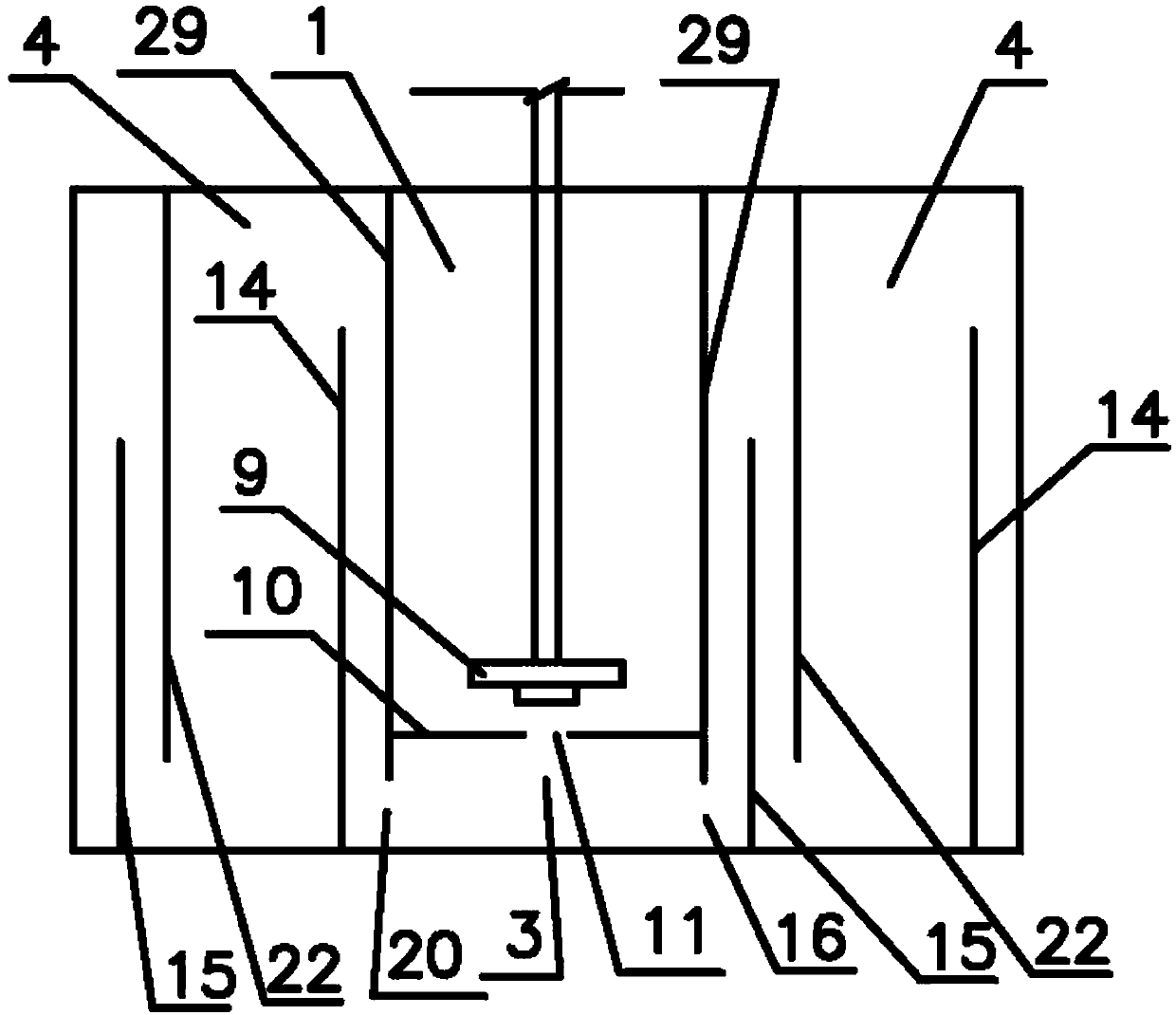

[0059] Such as Figure 1-7 As shown, the present embodiment provides a mixing and clarification tank, including: at least one clarification tank, the clarification tank includes: a mixing chamber 1, a clarification chamber 2, and a separation chamber 4 arranged in sequence and communicated, and the clarification tank also includes: 1 below and communicated with the submerged chamber 3, the separation chamber 4 includes: a heavy phase chamber 35, a light phase chamber 34, the light phase and the heavy phase enter the mixing chamber 1 to be mixed into a mixed phase, and then are transported to the clarified chamber 2, clarified chamber 2. It is used to separate the mixed phase into light phase and heavy phase, and send them into the light phase cell 34 and the heavy phase cell 35 respectively in the separation chamber 4, and flow out of the clarifier from the light phase cell 34 and the heavy phase cell 35; Chamber 4 also includes: a reflux chamber, and the mixing and clarificat...

Embodiment 3

[0108] Such as Figure 8 , 9 As shown, this embodiment provides a mixing and settling tank, and the difference from the mixing and settling tank in Example 2 is: the return pipeline includes: heavy phase return pipeline 26, and the return chamber includes: heavy phase return chamber 32, inside the separation chamber 4 The heavy phase of the heavy phase flows into the heavy phase reflux chamber 32, one end of the heavy phase reflux pipeline 26 is connected with the heavy phase reflux chamber 32, and the other end of the heavy phase reflux pipeline 26 is connected with the submerged chamber 3, when the light phase flow in the mixing and settling tank is greater than Heavy phase flow, the heavy phase return pipeline 26 is used to return the heavy phase back to the submerged chamber 3 . The connection between the heavy phase return pipeline 26 and the heavy phase return chamber 32 is close to the bottom plate 33 of the heavy phase return chamber. Specifically, the structure of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com