Veneer surface roughness and compressibility test method

A technology of surface roughness and testing method, applied in the fields of wood processing, wood-based panels, and automation, which can solve the problems of limited use, high labor intensity, and unsuitable for online testing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with accompanying drawing.

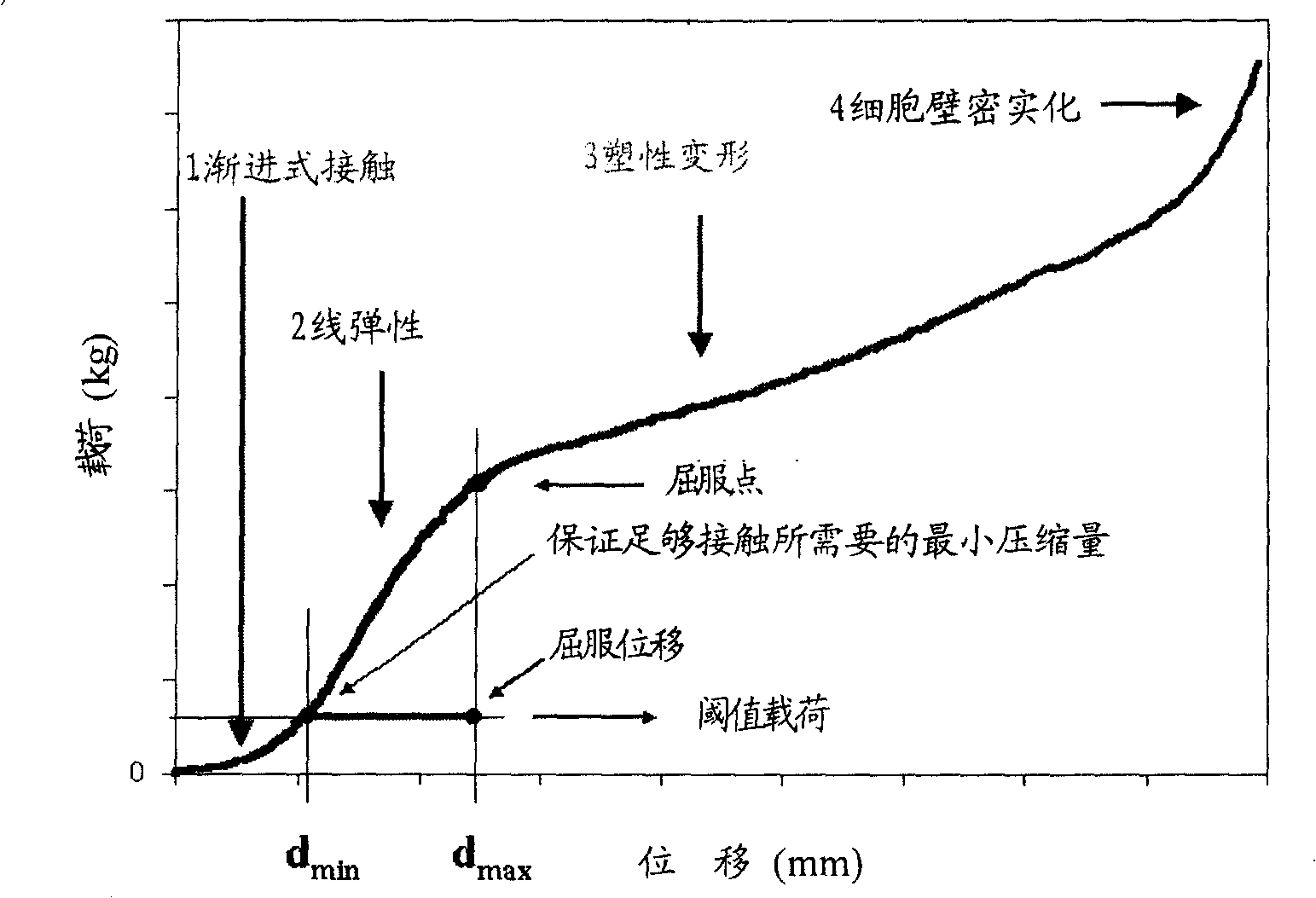

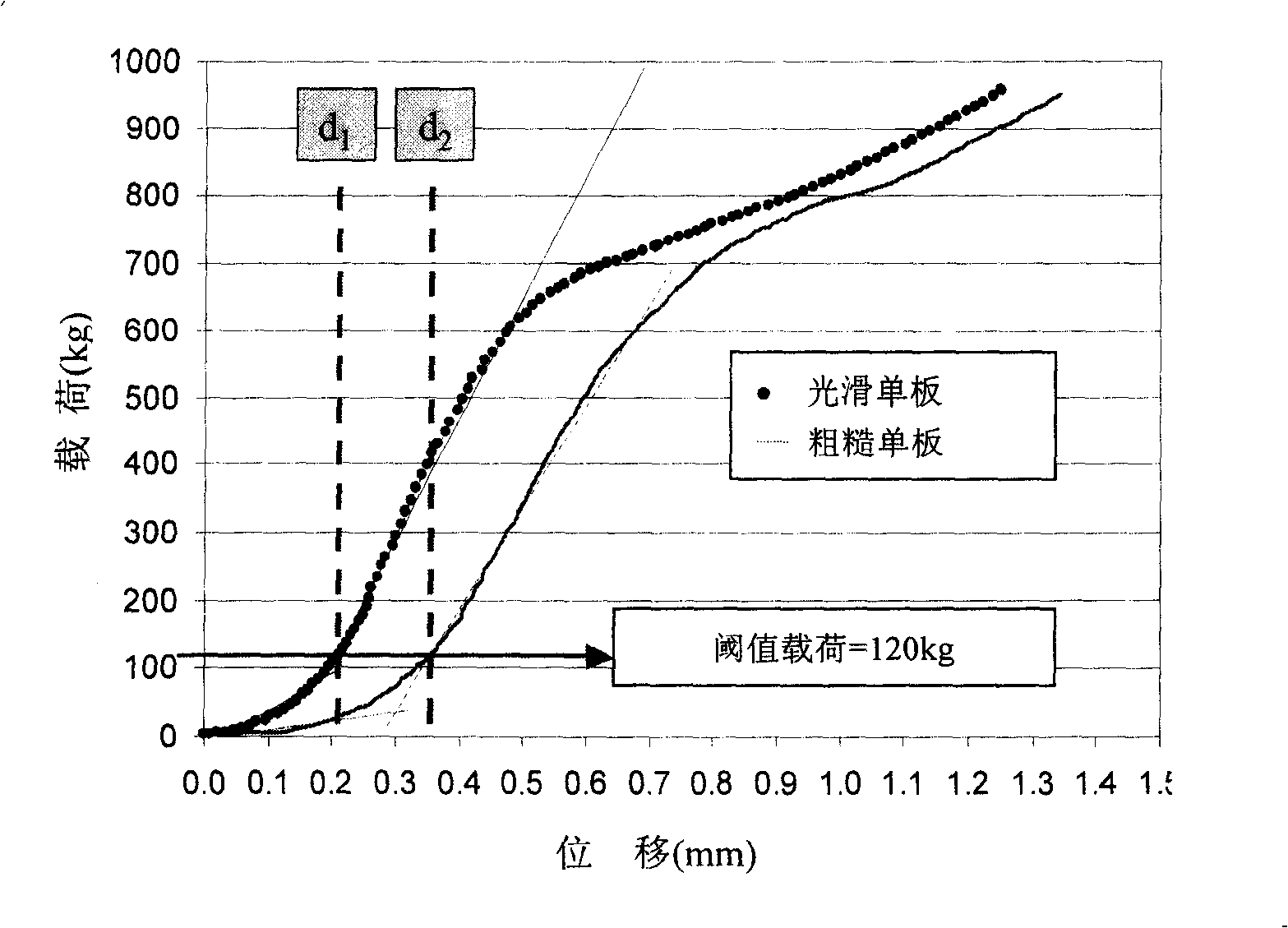

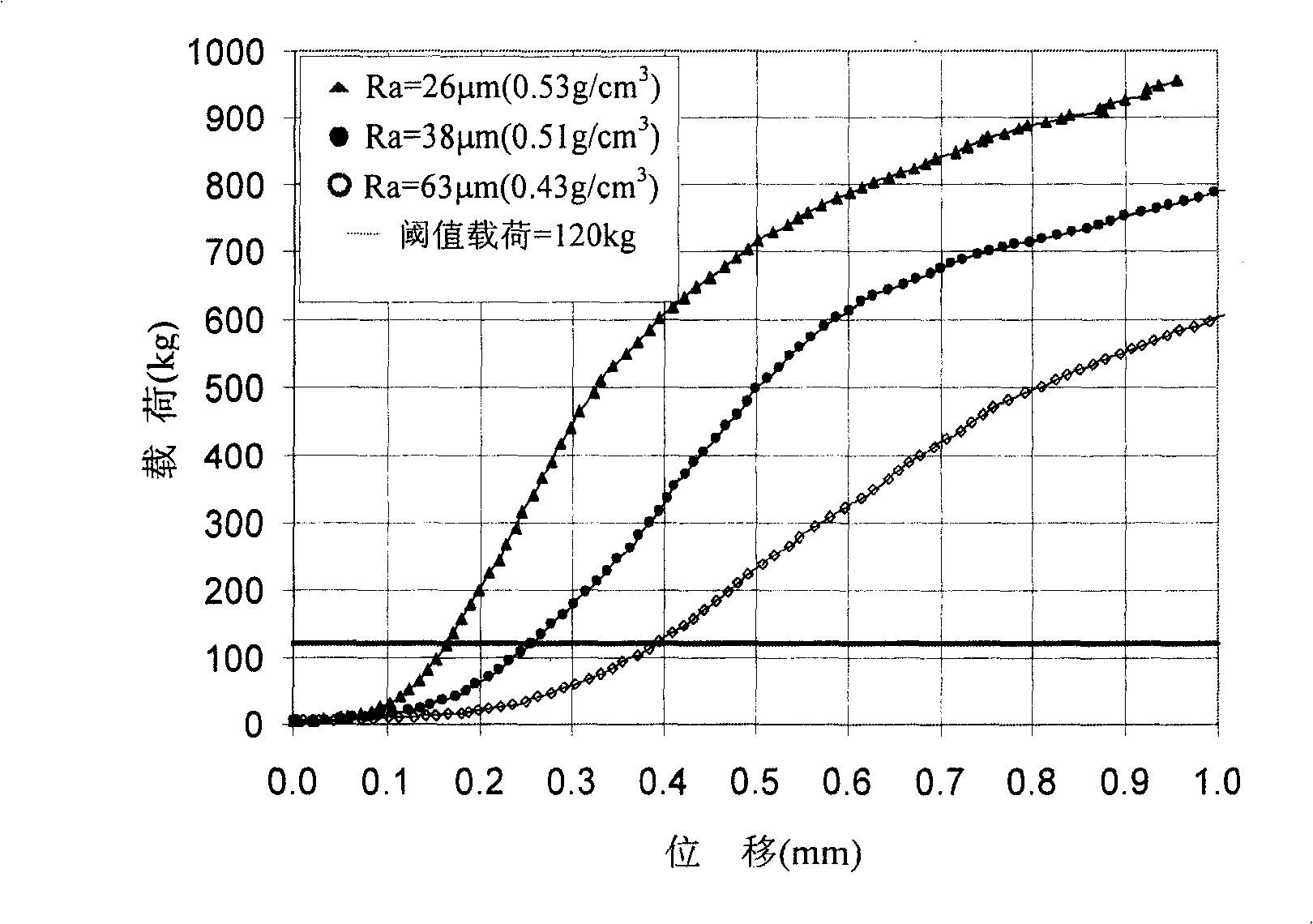

[0022] 1. Load-displacement curve of the veneer

[0023] For the radial compression of a single plate, the compression process actually goes through four stages ( figure 1 ), the stages of progressive contact, linear elasticity, plastic deformation, and cell wall densification. The first stage is the progressive contact stage, and the contact area between the veneers increases nonlinearly with the increase of the load. This stage directly reveals the interfacial contact between veneer and veneer, veneer and plate and the minimum amount of compression d required to ensure sufficient bonding area and strength min , the corresponding load is the threshold load; the second stage is the linear elastic stage, and the corresponding maximum displacement d max is the yield displacement.

[0024] In practical applications, the ideal compression should be between the minimum requi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com