Method for making compression components for rotating blade type compressor

A technology of rotary vane and manufacturing method, applied in rotary piston type machinery, rotary piston type/swing piston type pump components, rotary piston type pump, etc., can solve difficult adjustment of circular blade and annular space tolerance hard plate and inner Ring tolerance, influence on compressor torque, compressor performance degradation, etc

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

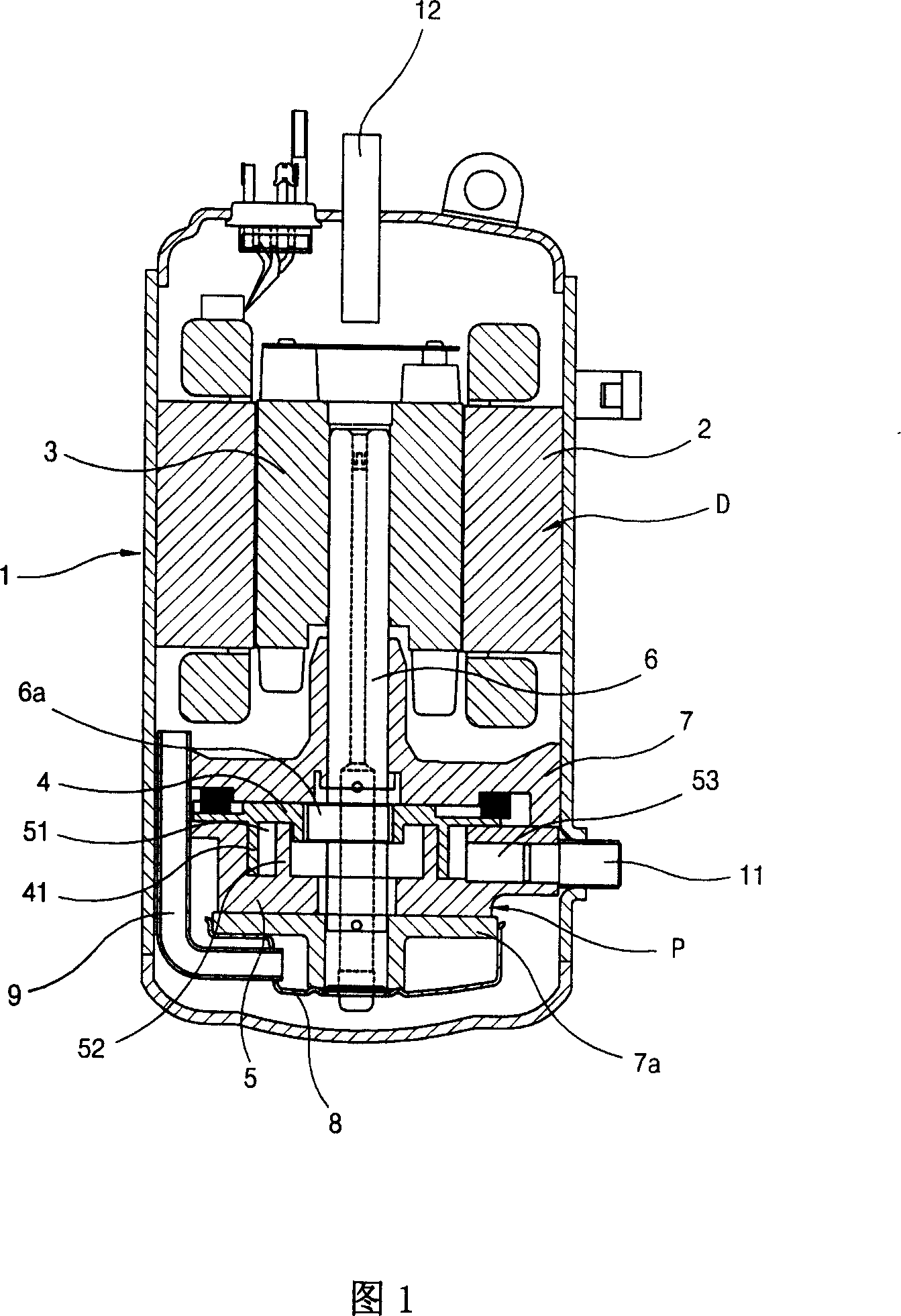

[0039]The present invention is described in further detail below in conjunction with the accompanying drawings and specific embodiments:

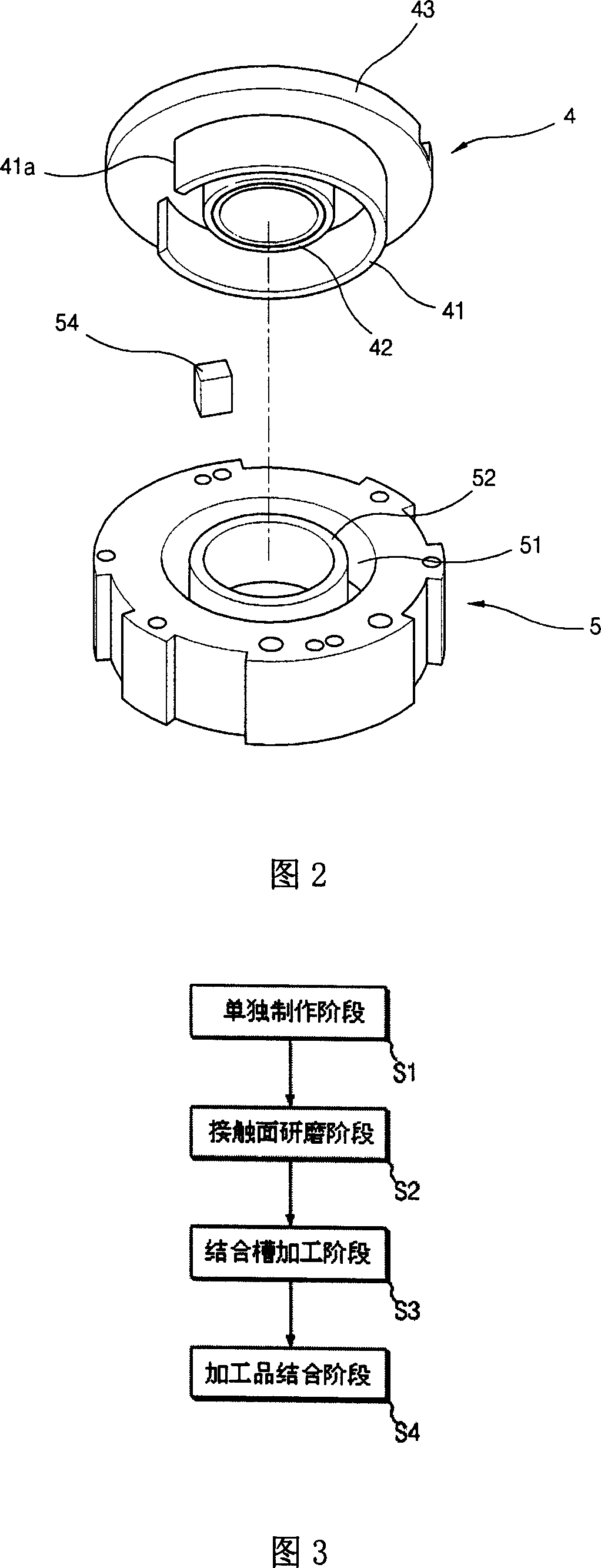

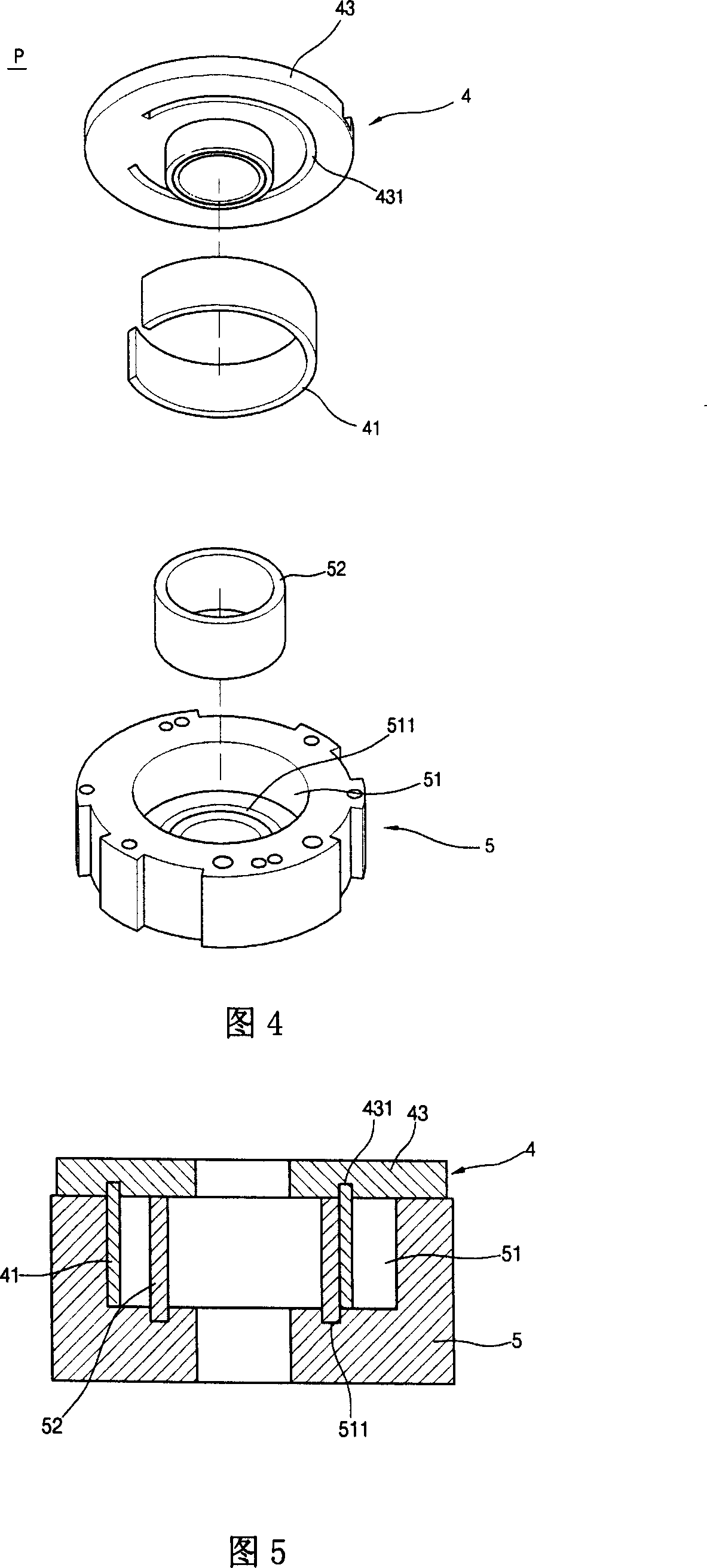

[0040] As shown in FIG. 3 , the manufacturing method of the compression part of the rotary vane compressor of the present invention includes a separate manufacturing stage S1 for separately manufacturing the components that need to be ground, and a contact surface grinding stage S2 for grinding the contact surfaces of the separately manufactured components, The joining groove processing stage S3 in which joining grooves are machined on the components to be joined is constituted by the processing product joining stage S4 in which the components are joined to each other through the joining grooves.

[0041] The separate production stage S1 refers to the stage of separately producing the circular blade and the hard plate of the rotating blade, and separately producing the cylinder with the annular space and the inner ring.

[0042] In the abov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com