Cable drag chain

A cable and towline technology, applied in the installation of towlines, suspension chains, cables, etc., can solve problems such as poor production efficiency and attenuation of braking effects, and achieve the effects of excellent productivity, easy formation, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

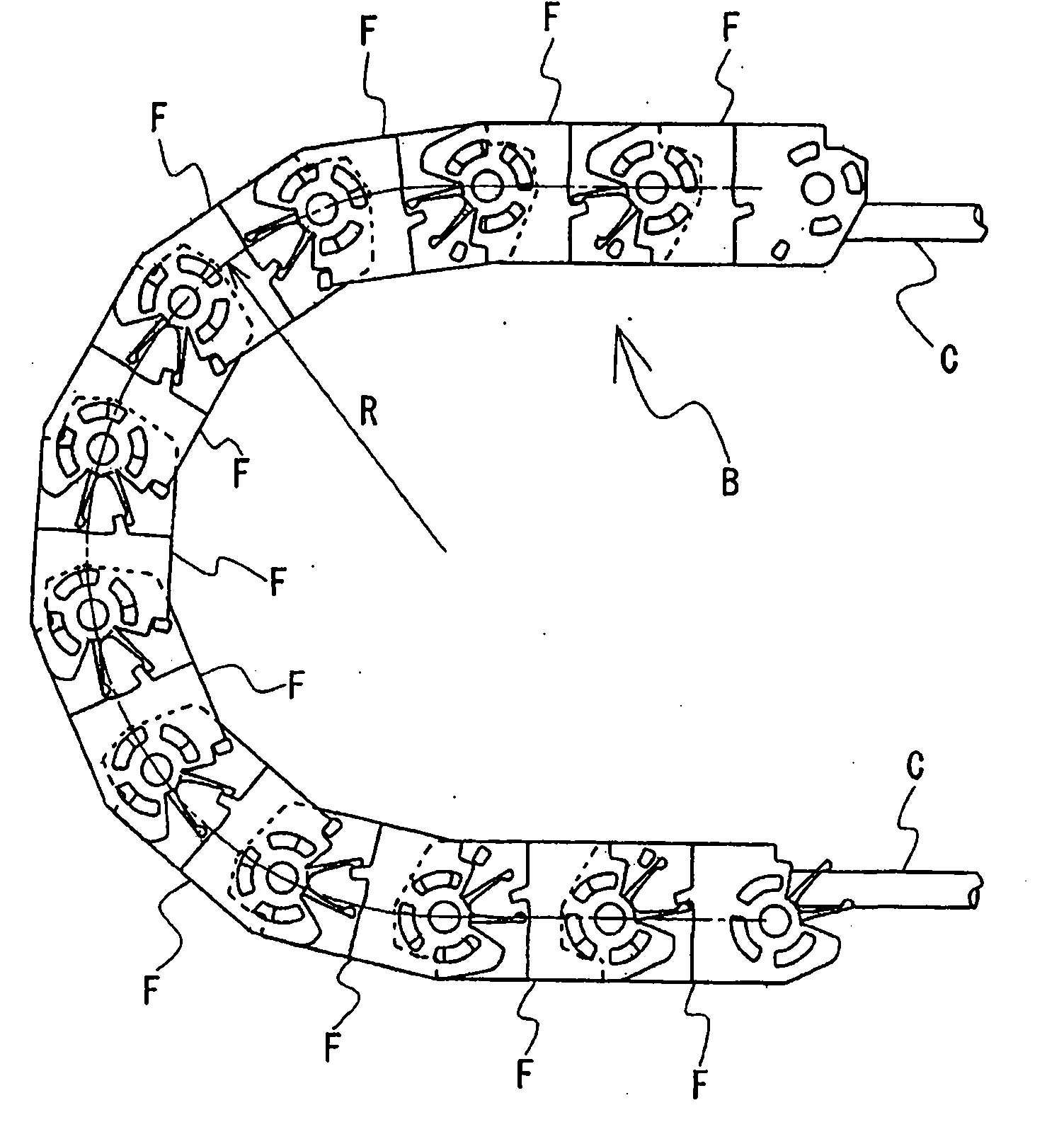

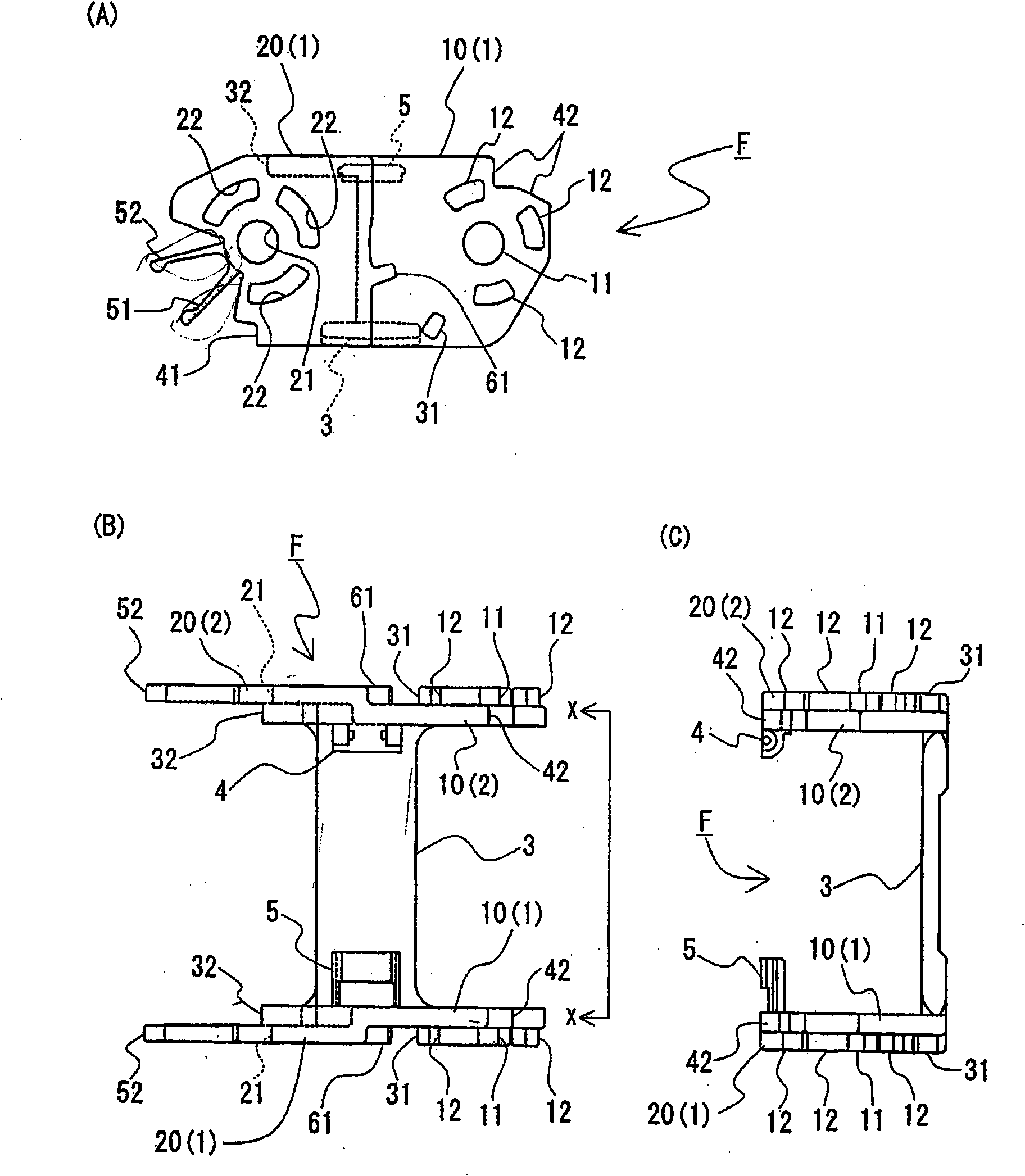

[0036] figure 1 It is a schematic configuration diagram of the cable drag chain of this embodiment. The cable drag chain B guides and protects the cable C for supplying electric power and the like to a moving body. This cable drag chain B is formed by connecting a plurality of frame bodies F flexibly, and the cable C can be arranged in a guide part formed inside the frame body F connected. Generally, the cable drag chain B is used so that at least one of both end parts is connected to a mobile body, and the middle part is folded back in U shape, and the folded-back position moves with the movement of a mobile body. Here, the rotation angle of each frame F constituting the cable chain B with respect to the adjacent frame F is restricted by the rotation angle limiting mechanism, and the cable chain B connecting these frames F cannot bend with a predetermined bending radius (Fig. In the R) below the bending radius bending. Therefore, the cable C arrange|positioned in the cable...

Embodiment approach 2

[0051] Embodiment 2 demonstrates the cable drag chain which used the frame body which provided one elastic protrusion and two receiving parts on one side panel of a frame body. In addition, the same code|symbol as Embodiment 1 is attached|subjected to the same structure as Embodiment 1, and description is abbreviate|omitted.

[0052] Figure 4 It is an explanatory drawing which shows the connection state of the housing|casing which comprises the cable drag chain of this embodiment. On the side panel 1 of the frame body F, an elastic protrusion 55 protruding from the side is formed. In addition, two receiving portions 65 , 66 corresponding to the elastic protrusion 55 are formed. Specifically, the receiving portions 65 and 66 are formed at predetermined intervals on the circumference centered on the shaft portion 11 of the inner portion 10, and when the frames F are connected, the front ends of the elastic protrusions 55 of the adjacent frames F are sandwiched from both sides...

Embodiment approach 3

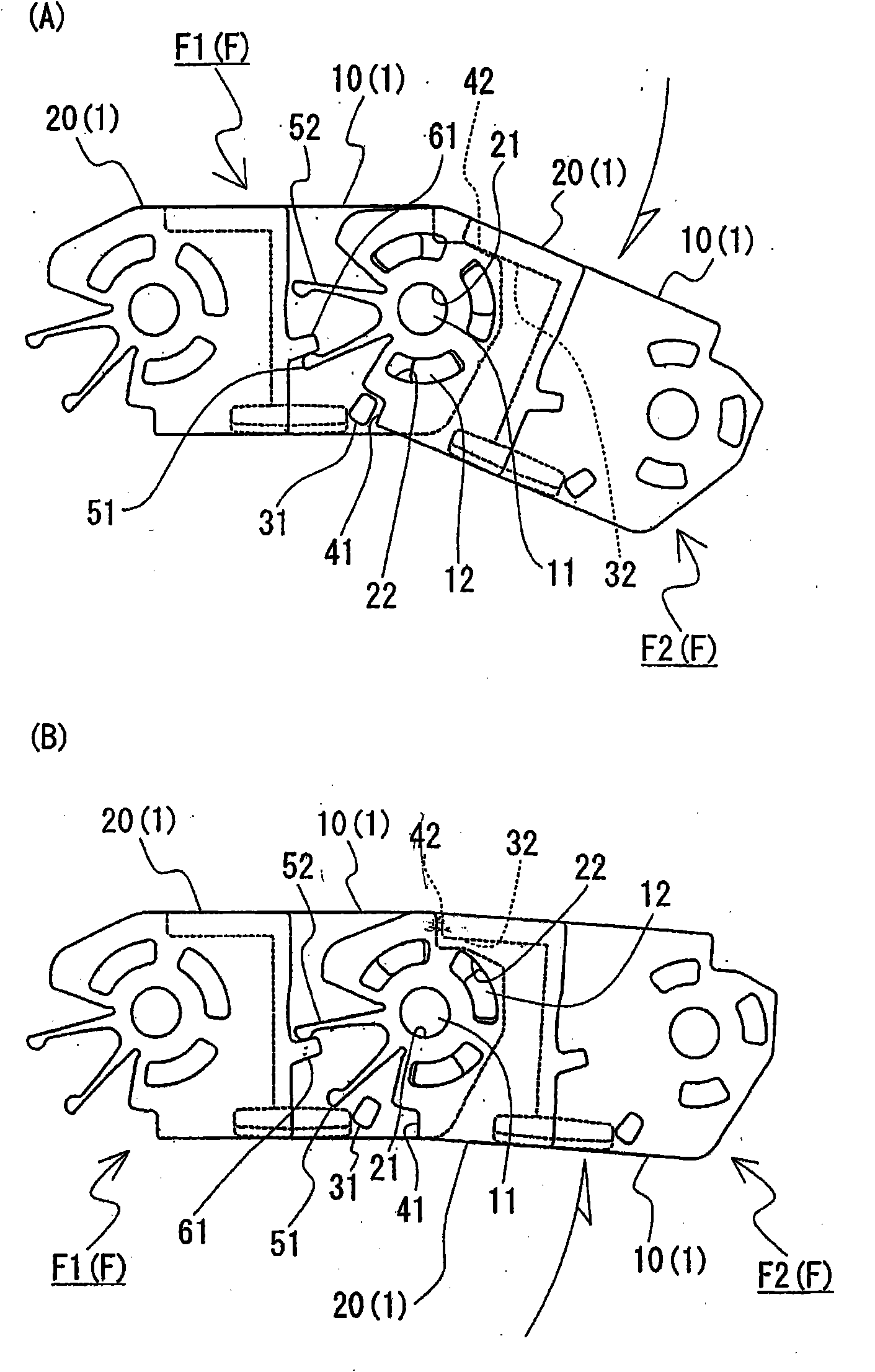

[0055] In embodiment 3, according to Figure 5 A structure in which the rotation of the housing is braked by friction when the elastic protrusions contact the receiving portion and the elasticity of the elastic protrusions is used to adjust the frictional force will be described.

[0056] Figure 5 It is an explanatory drawing which shows the connection state of the housing used for the cable drag chain of this embodiment. The elastic projections 71 and 72 provided on the frame body F extend outward in the radial direction from the two side edges of the side panel 1 with the shaft hole 21 and the shaft portion 11 as the center respectively, and then form a curved arm shape extending in the circumferential direction. . The bending directions of the elastic protrusions 71 and 72 are both clockwise, and the two elastic protrusions 71 and 72 are approximately point-symmetrical. In addition, the receiving portion 81 corresponding to the elastic protrusion 71 is on the side of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com