Mold, mold temperature regulation method, mold temperature regulation device, injection molding method, injection molding machine, and thermoplastic resin sheet

A technology for mold temperature and adjustment equipment, which is applied in the fields of molds, mold temperature adjustment, mold temperature adjustment equipment, injection molding, injection molding machines, and thermoplastic resin sheets, and can solve problems such as low production capacity, long molding cycle, and complicated control devices. problem, to achieve the effect of easy access and excellent productivity

Active Publication Date: 2008-10-15

MITSUBISHI HEAVY IND LTD +1

View PDF1 Cites 11 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The molding method according to a conventional example as described in Japanese Patent No. 3601463 is configured to preheat the cavity surface of the mold to or above the glass transition temperature to obtain good flowability of the resin material at a lower injection rate. The molten resin is injected into the cavity at a high speed, and the mold is cooled, and the molded article is removed from it. As a result, the method has an excellent performance in the fine reproduction rate of the surface of the molded article, but due to a longer molding cycle, it exhibits The problem of low production capacity

Meanwhile, the injection molded article production method according to the conventional example as described in JP-2004-322597A requires a system of three temperature adjustment devices, a cooperative heat medium supply device, a heat medium recovery tank, etc., to control high temperature, medium temperature, and The three types of low-temperature heat media are supplied separately, so the number of devices is large and the control devices are complicated

Also, since the medium-temperature heat medium must be kept supplied for a long time to prevent the temperature rise due to the molten resin in the injection process and the pressure-holding process by keeping the mold at a medium temperature, and since the molded Items take a long time to cool, and the molding cycle time is greatly extended, which significantly increases the amount of heat medium circulation and heat energy consumed

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

example 1、2

example 3

example 1、3、4

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

Login to View More

Abstract

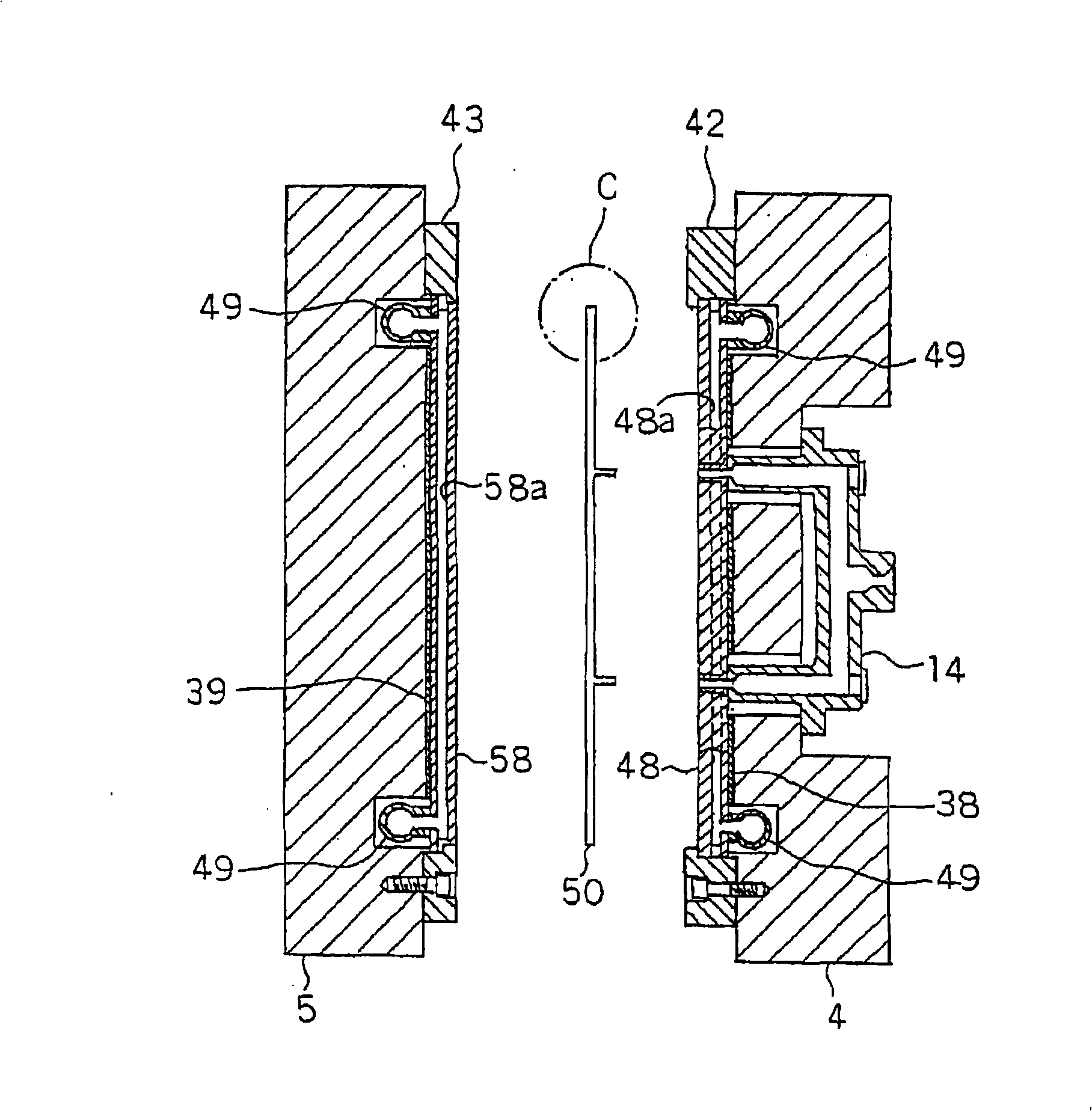

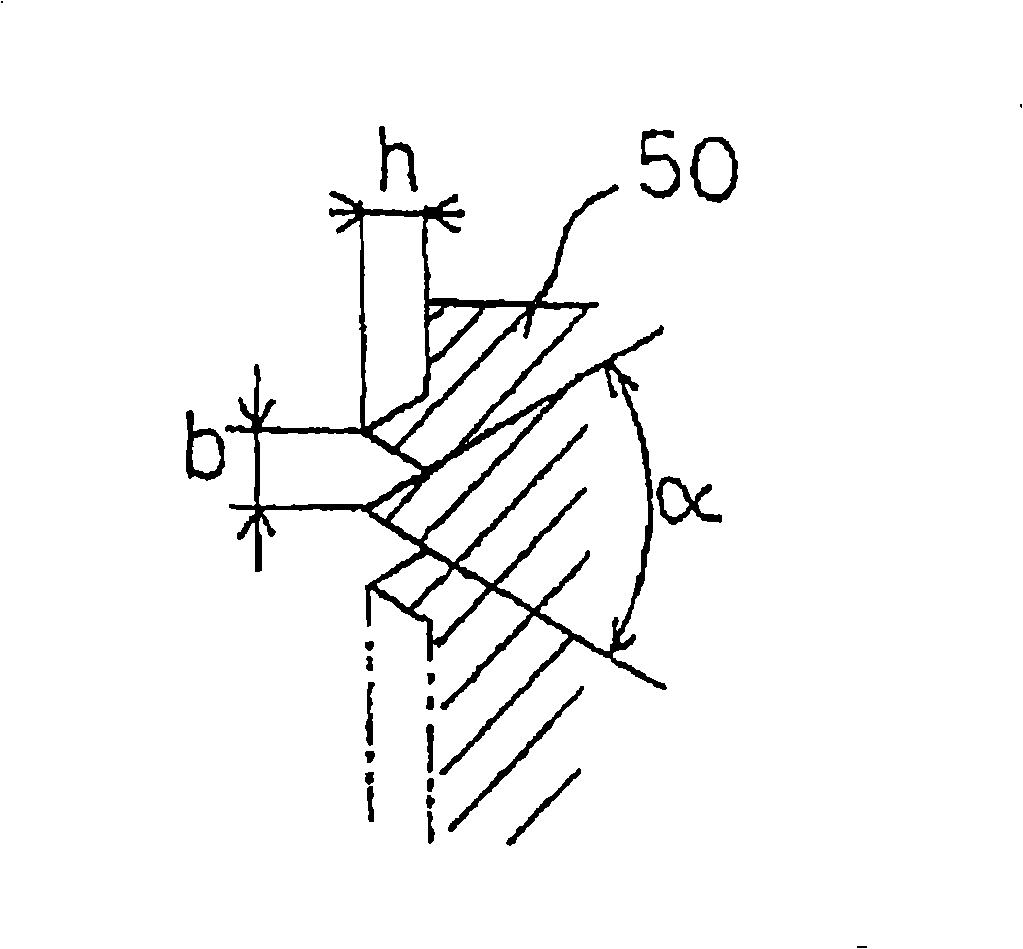

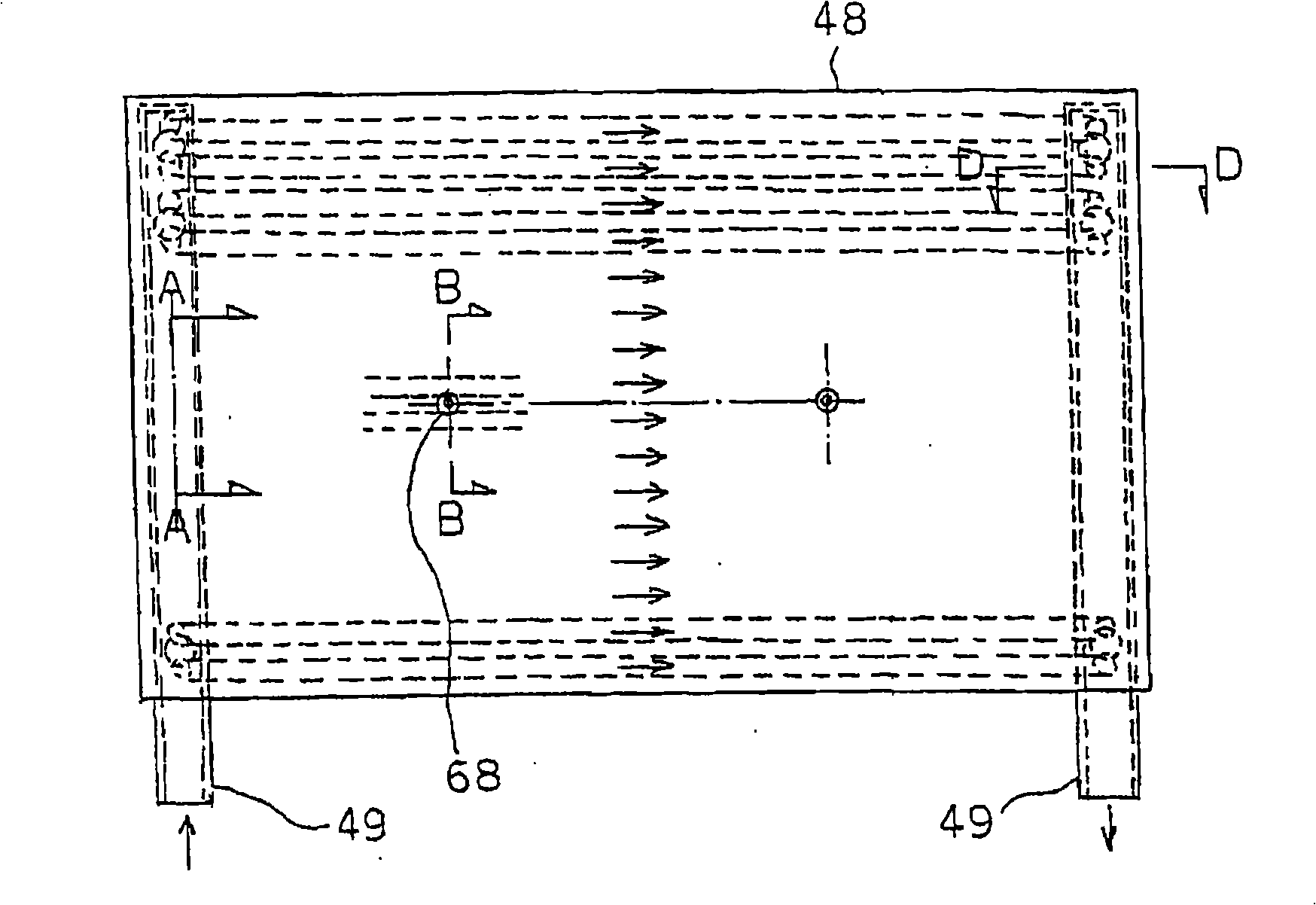

The present invention provides a mold, mold temperature regulation method, mold temperature regulation device, injection molding method, injection molding machine, and thermoplastic resin sheet, the mold made of by certain material can enhance the transferability of the surface of a molded product and can allow the molded product to be taken out immediately after the solidification, whereby molding cycle can be accelerated. In the mold, both a stationary side mold and a movable side mold are mounted within masters, and a cavity face is formed on a release side. A plurality of heating medium passages are bored at a position distant by a given distance from the cavity face. The mold comprises a 15 to 30 mm-thick rectangular bushes formed of a metal having a coefficient of thermal conductivity of 20 to 40 W / (m K), heat insulating plates having a coefficient of thermal conductivity of not more than 5 W / (m K) and held between the masters and the bushes, a pair of heating medium manifolds (mounted on both ends of the anticavity face of the bushes so as to be led to the heating medium passages of the bushes, and a plurality of pressing members for pressing four edges of the bushes to fix the bushes to the masters.

Description

Mold, mold temperature adjustment method, mold temperature adjustment device, injection molding method, injection molding machine, and thermoplastic resin sheet technical field The present invention relates to a mold for an injection molding machine for molding a thin plate made of thermoplastic resin, such as a light guide plate, a diffuser plate, etc., which has an integral body formed in a large number of fine dimples and protrusions in a pattern and more specifically, a mold, a mold temperature adjusting method, a mold temperature adjusting device, an injection molding method, an injection molding machine, and a thermoplastic resin sheet, all of which are combined in cooperation by using a mold made of one material The method is configured to enhance the transferability (transferability) of the surface of the molded article so that the molded article can be removed immediately after curing, thereby speeding up the molding cycle, wherein the material has such a thermal cond...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B29C33/04B29C33/38B29C45/27B29C45/73B29C45/78

CPCB29C45/7312B29C33/04B29C45/2675B29C45/2737B29C45/372B29C45/73B29C45/7306B29C45/78B29C2033/023B29C2045/7325B29C2045/7356B29C2045/7606B29C2945/76531B29C33/38B29C45/27

Inventor 别所正博上地哲男村中治宫川智志户田直树渡边吉典

Owner MITSUBISHI HEAVY IND LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com