Composite biopolysaccharide magnetic microsphere preparation method

A technology of biological polysaccharides and magnetic microspheres, which is applied in the field of preparation of composite biological polysaccharide magnetic microspheres, can solve the problems of large swelling volume, high cost, and poor acid resistance of magnetic microspheres, and achieve small swelling coefficient, high resistance Strong acidity and alkalinity, wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A kind of tamarind gum composite magnetic microsphere preparation method of the present invention is as follows:

[0035] 1. Preparation of water-soluble magnetic fluid: Mix ferrous sulfate aqueous solution and ferric chloride aqueous solution, add polyethylene glycol with a molecular weight of 10,000 under the condition of pH>11, 50°C, raise the temperature to 80°C, and react for 30 minutes. Naturally cool to room temperature, neutralize to neutral with dilute hydrochloric acid, let stand, remove the supernatant, that is, the water-soluble magnetic fluid is prepared, and set aside;

[0036] Wherein, the molar concentration of ferrous sulfate aqueous solution is 1 mole / liter; The molar concentration of ferric chloride aqueous solution is 1 mole / liter; The volume ratio of ferrous sulfate aqueous solution and ferric chloride aqueous solution consumption is 1: 2; Molecular weight is The amount of 10000 polyethylene glycol added in the mixed aqueous solution of ferrous sulf...

Embodiment 2

[0055] A kind of tamarind gum composite magnetic microsphere preparation method of the present invention is as follows:

[0056] 1. Preparation of water-soluble magnetic fluid: Mix ferrous sulfate aqueous solution and ferric chloride aqueous solution, add polyethylene glycol with a molecular weight of 10,000 under the condition of pH>11 and 60°C, raise the temperature to 80°C, and react for 50 minutes , naturally cooled to room temperature, neutralized to neutral with dilute hydrochloric acid, allowed to stand, and removed the supernatant to obtain a water-soluble magnetic fluid for subsequent use;

[0057] Wherein, the molar concentration of ferrous sulfate aqueous solution is 1.25 mol / liter; The molar concentration of ferric chloride aqueous solution is 2 mol / liter; The volume ratio of ferrous sulfate aqueous solution and ferric chloride aqueous solution consumption is 1: 1.25; Molecular weight is The amount of polyethylene glycol of 10000 in the mixed aqueous solution of fe...

Embodiment 3

[0076] A kind of tamarind gum composite magnetic microsphere preparation method of the present invention is as follows:

[0077] 1. Preparation of water-soluble magnetic fluid: Mix ferrous sulfate aqueous solution and ferric chloride aqueous solution, add polyethylene glycol with a molecular weight of 10,000 under the condition of pH>11, 55°C, raise the temperature to 80°C, and react for 40 minutes. Naturally cool to room temperature, neutralize to neutral with dilute hydrochloric acid, let stand, remove the supernatant, that is, the water-soluble magnetic fluid is prepared, and set aside;

[0078] Wherein, the molar concentration of ferrous sulfate aqueous solution is 1.12 mol / liter; The molar concentration of ferric chloride aqueous solution is 1.5 mol / liter; The volume ratio of ferrous sulfate aqueous solution and ferric chloride aqueous solution consumption is 1: 1.5; Molecular weight is The amount of polyethylene glycol of 10000 in the mixed aqueous solution of ferrous su...

PUM

| Property | Measurement | Unit |

|---|---|---|

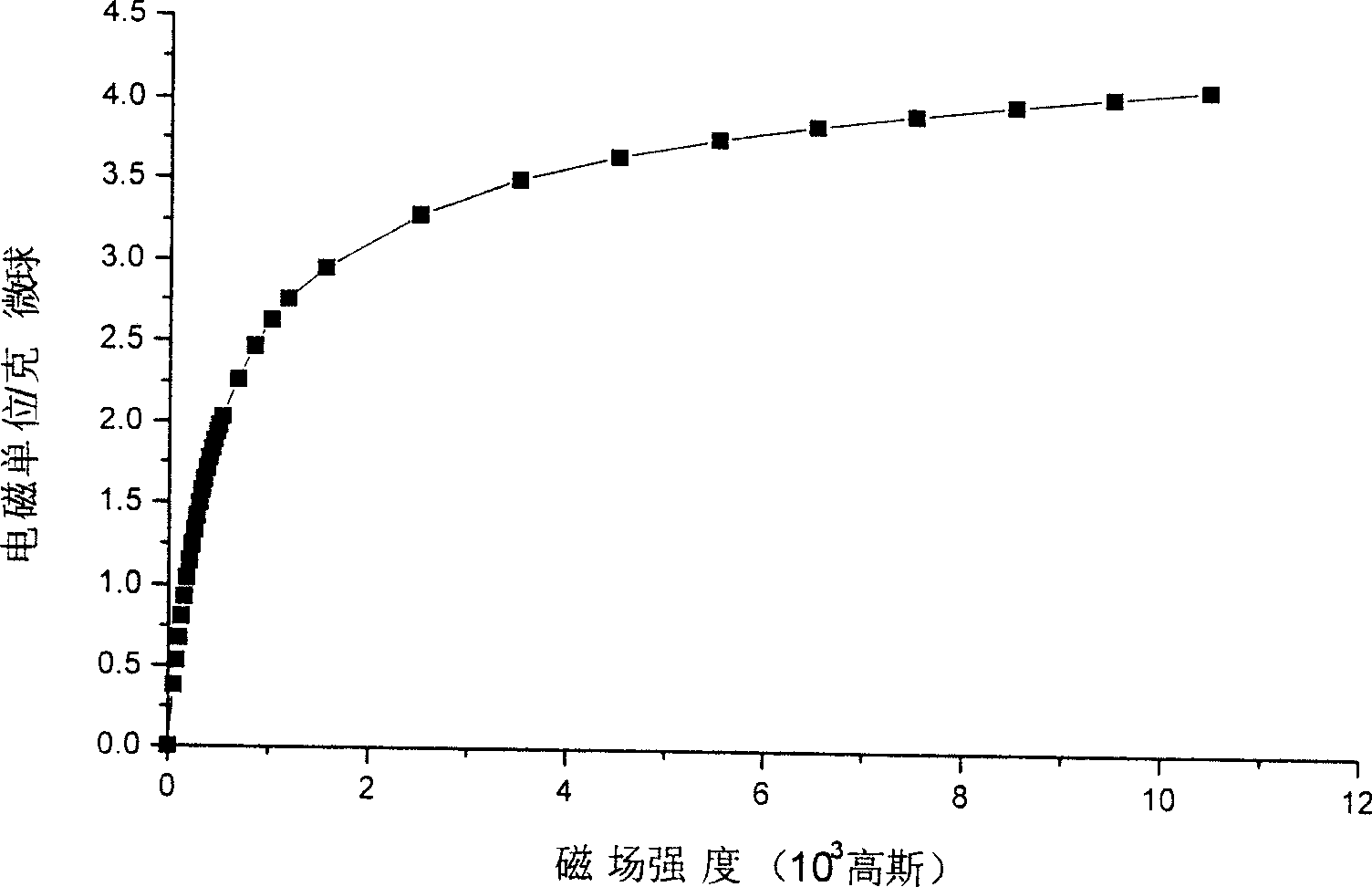

| swelling factor | aaaaa | aaaaa |

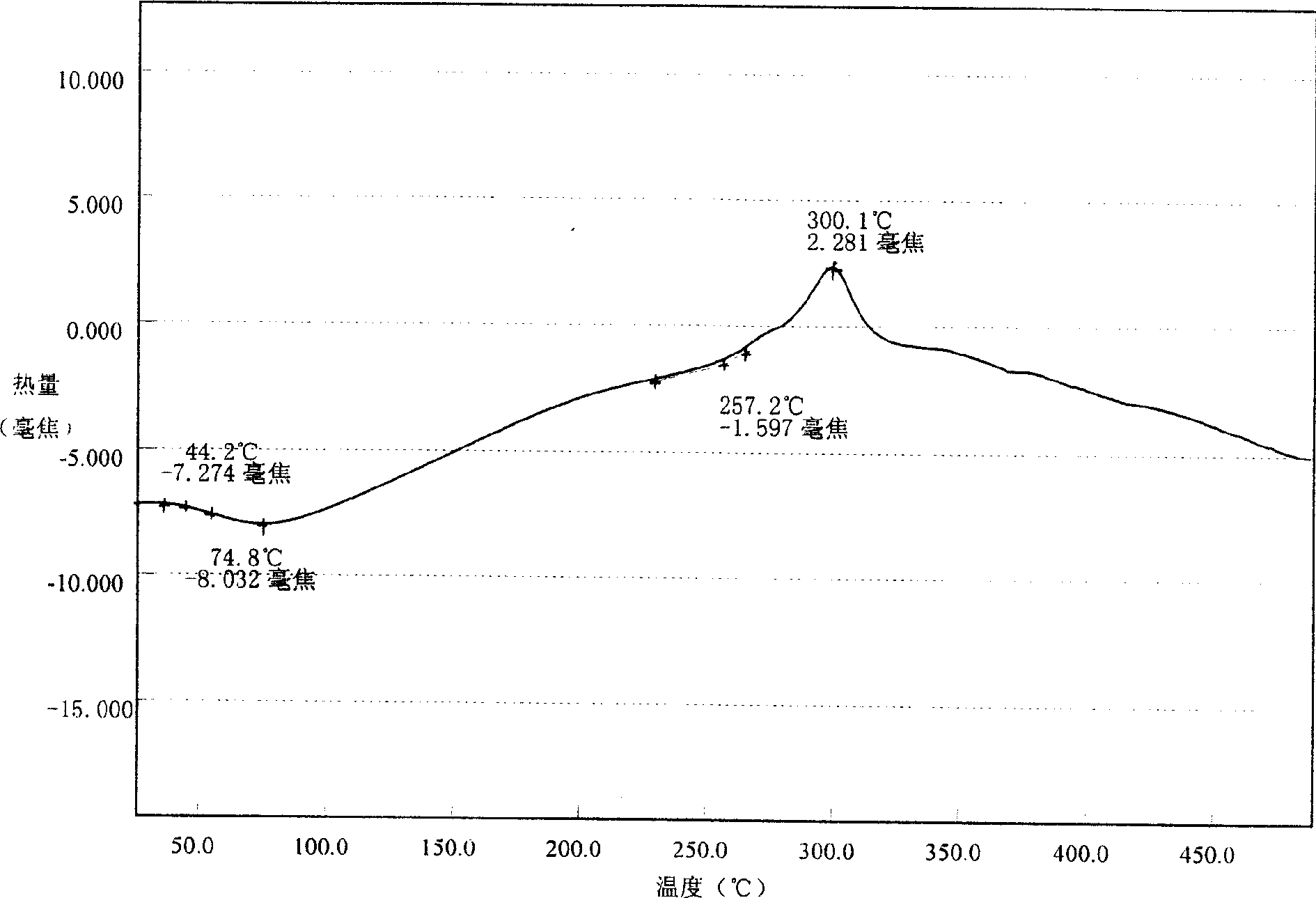

| decomposition temperature | aaaaa | aaaaa |

| swelling factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com