Method for manufacturing glass and glass

A manufacturing method and glass technology, applied in glass manufacturing equipment, glass tempering, manufacturing tools, etc., can solve the problems of rising manufacturing costs, poor productivity, high frequency of molten salt replacement, etc., to achieve reduced replacement frequency, increased surface compressive stress, The effect of high-strength protective performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

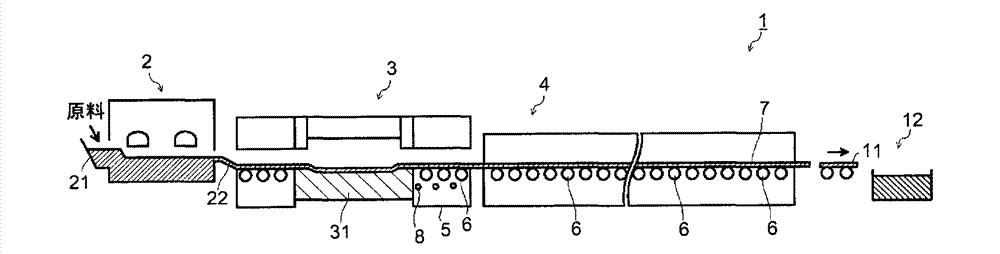

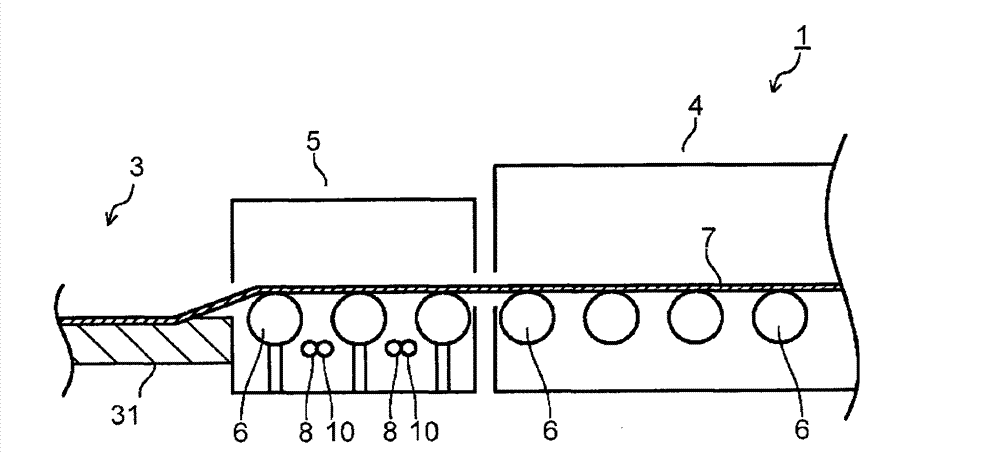

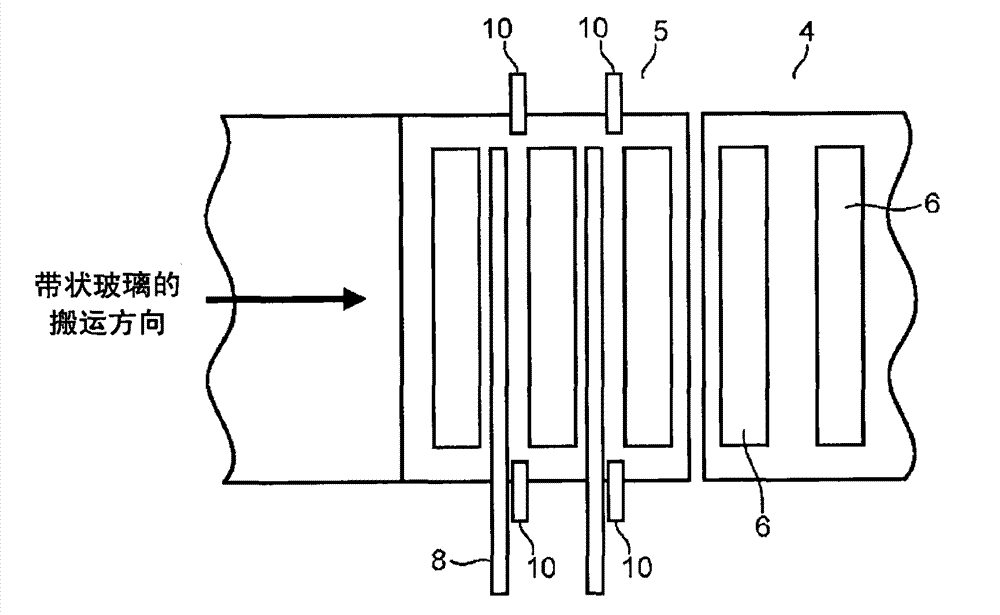

[0118] First, expressed as SiO in terms of mole percentages based on oxides 2 64.3%, Na 2 O 12.0%, K 2 O 4.0%, MgO 11.0%, CaO 0.1%, SrO 0.1%, Al 2 o 3 6.0% and ZrO 2.5% are blended and mixed, and the raw material mixture is put into a melting furnace and melted at about 1500° C., and then the molten glass is supplied into the float tin bath 3 . In the float tin bath 3 , glass is formed into ribbons on molten tin, and the glass is conveyed to the rear part 5 of the shield.

[0119] In the rear part 5 of the protective cover, as a sodium concentration reduction treatment, sulfurous acid gas is sprayed on the glass surface to make Glauber's salt (NaSO 4 ) precipitated on the glass surface.

[0120] Next, after cooling, it was cut to an appropriate size to obtain plate-shaped glass with a thickness of 1 mm.

[0121] This glass is not subjected to water washing treatment but to chemical strengthening treatment. Chemical strengthening treatment using potassium nitrate (KNO ...

Embodiment 2

[0123] Glass was prepared in the same manner as in Example 1, except that the glass cut into a plate was washed with water prior to the chemical strengthening treatment.

Embodiment 3

[0125] Glass was prepared in the same manner as in Example 1, except that the amount of sulfurous acid gas sprayed onto the glass surface was larger than in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adhesion amount | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| compressive stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com