Urethane-based pressure-sensitive adhesive and surface protective film using the pressure-sensitive adhesive

A technology based on pressure-sensitive adhesives and polyurethane-based resins, used in polyurea/polyurethane adhesives, adhesives, pressure-sensitive films/sheets, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

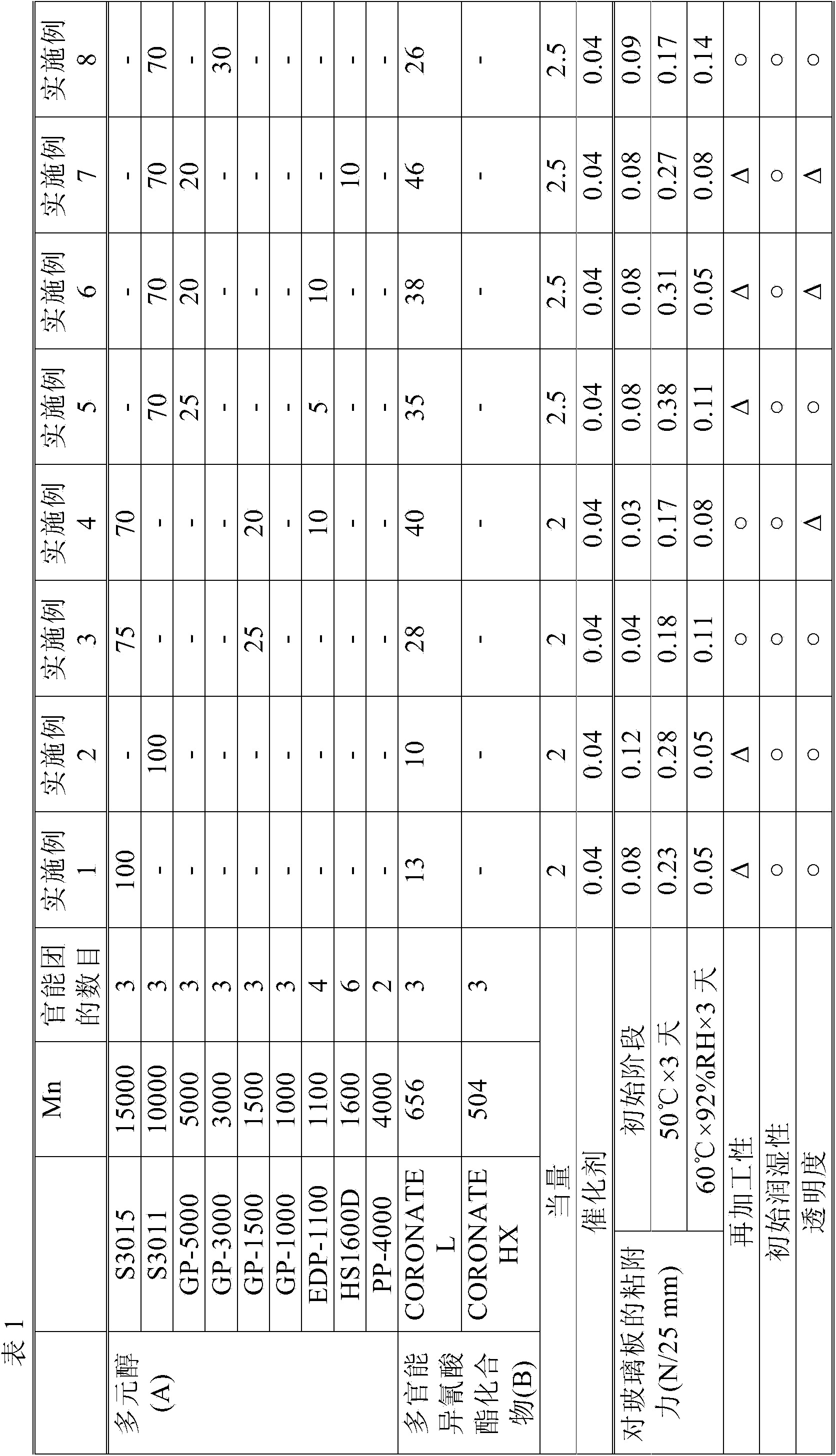

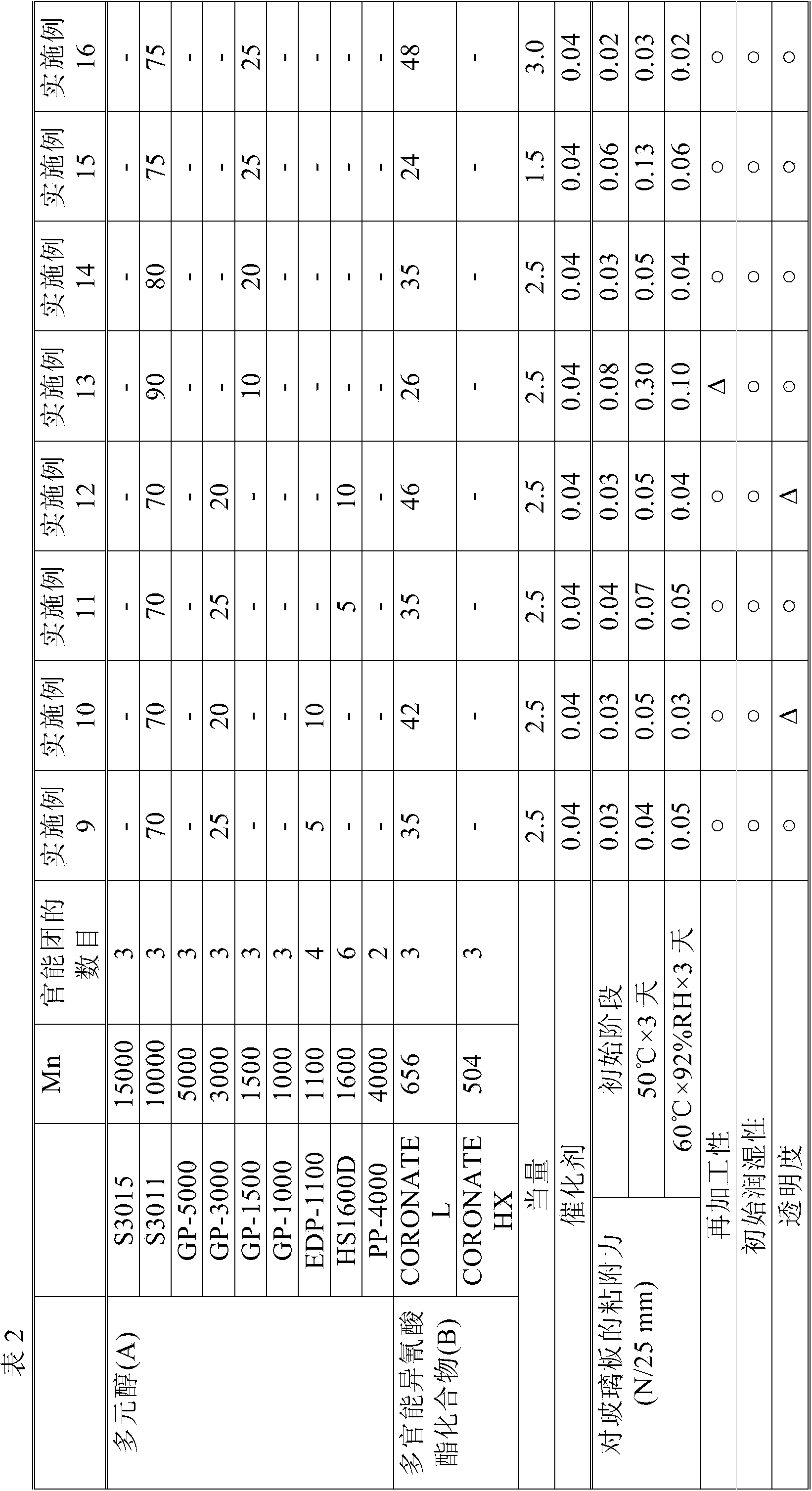

[0228] 100 parts by weight of the polyol (A) were PREMINOL S3015 (manufactured by ASAHI GLASS CO., LTD., Mn=15000), which is a polyol having 3 OH groups, a polyfunctional isocyanate compound (B) 13 parts by weight of an adduct of trimethylolpropane / toluene diisocyanate trimer (manufactured by Nippon Polyurethane Industry Co., Ltd., trade name: CORONATE L), 0.04 parts by weight of a catalyst (manufactured by NIHON KAGAKUSANGYO CO., LTD., trade name: Nacem Ferric Iron) and 210 parts by weight of ethyl acetate as a dilution solvent were mixed, and then dispersed using stirring with a mixer to provide a polyurethane-based pressure-sensitive adhesive composition. The obtained polyurethane-based pressure-sensitive adhesive composition was applied to a base material "Lumirror S10" (thickness: 38 μm, manufactured by Toray Industries, Inc.) formed of polyester resin with a dipping roller so that the After drying, its thickness was 12 μm, and then the composition was cured and dried un...

Embodiment 2

[0232] A pressure-sensitive adhesive layer formed of a polyurethane-based pressure-sensitive adhesive (2) was produced on a substrate in the same manner as in Example 1 except that 100 parts by weight of PREMINOL S3011 (manufactured by Asahi Glass Co., Ltd., Mn=10000) was used as polyol (A); and 10 parts by weight of trimethylolpropane / toluene diisocyanate trimer adduct (manufactured by Japan Polyurethane Industry Co., Ltd. , trade name: CORONATE L) was used as the polyfunctional isocyanate compound (B).

[0233] Next, the silicone-treated surface of a 25 μm-thick substrate formed of a polyester resin and one surface of which was silicone-treated was attached to the surface of the pressure-sensitive adhesive layer to provide a surface protective film ( 2).

[0234] Table 1 shows the evaluation results.

Embodiment 3

[0236] A pressure-sensitive adhesive layer formed of a polyurethane-based pressure-sensitive adhesive (3) was produced on a substrate in the same manner as in Example 1 except that 75 parts by weight of PREMINOL S3015 (manufactured by Asahi Glass Co., Ltd., Mn=15000) and 25 parts by weight of SANNIXGP-1500 (manufactured by Sanyo Chemical Industries, Ltd., Mn=1500) which is a polyol having 3 OH groups used as polyol (A); and 28 parts by weight of trimethylolpropane / toluene diisocyanate trimer adduct (manufactured by Nippon Polyurethane Industry Co., Ltd., trade name: CORONATE L) was used as polyfunctional isocyanate compound (B).

[0237] Next, the silicone-treated surface of a 25 μm-thick substrate formed of a polyester resin and one surface of which was silicone-treated was attached to the surface of the pressure-sensitive adhesive layer to provide a surface protective film ( 3).

[0238] Table 1 shows the evaluation results.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com