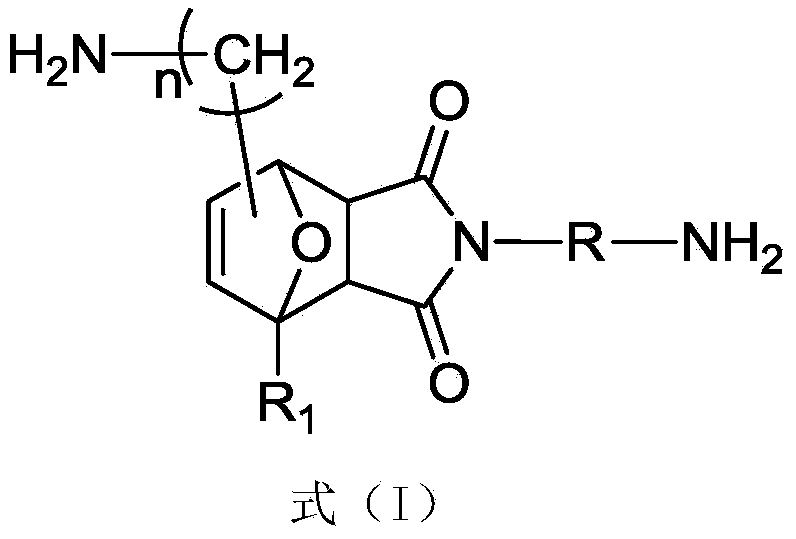

Diamine addition crosslinking agent and preparation method thereof, as well as composition for preparing thermal reversible crosslinking epoxy resin and composite material of thermal reversible crosslinking epoxy resin

A technology of amine adducts and cross-linking agents, applied in the field of reversible cross-linked epoxy resin and its composite materials, can solve the problem of lack of multiple repairs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0074] Embodiment 1, the synthesis of diamine adduct crosslinking agent

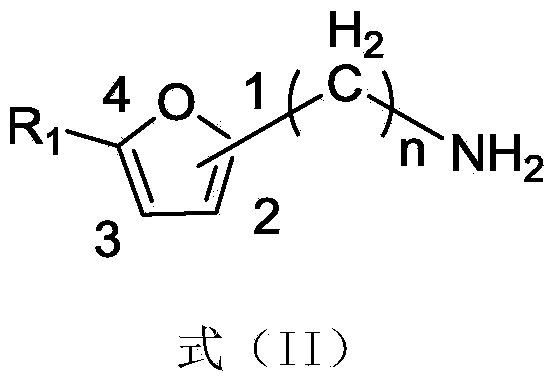

[0075] (1) prepare the methyl furanamine of Boc protection

[0076] In a 500 mL single-necked round bottom flask, 25.20 g (0.115 mol) of di-tert-butyl dicarbonate was dissolved in 90 mL of dichloromethane and placed in an ice bath at 0°C. In addition, 10.60 g (0.109 mol) of furylamine was dissolved in 90 mL of dichloromethane, added into the reaction bottle, and reacted at room temperature for 24 hours after addition. The solvent was removed by rotary evaporation, 50 mL of ethyl acetate was added, washed once with 40 mL of saturated aqueous sodium carbonate solution, and then washed once with 40 mL of saturated brine, dried with anhydrous sodium sulfate, and the solvent was removed by a vacuum rotary evaporator to obtain 21.55 g yellow crystals, that is Boc-protected furylamine, the conversion rate is 99%.

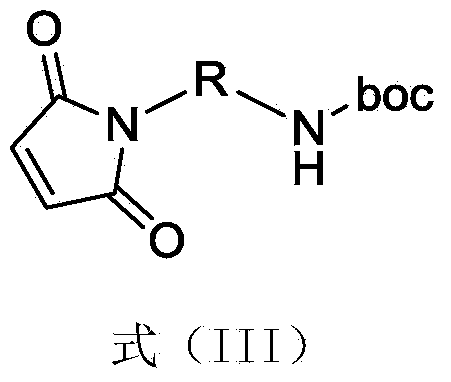

[0077] (2) Preparation of N-substituted maleimides of Boc-protected amino groups

[0078] To a...

Embodiment 2

[0086] Embodiment 2, the synthesis of diamine adduct crosslinking agent

[0087] (1) prepare the methyl furanamine of Boc protection

[0088] Synthetic method is identical with embodiment 1.

[0089] (2) Preparation of N-substituted maleimides of Boc protected amino groups

[0090] Mono-Boc-protected hexamethylenediamine was prepared by the method disclosed in the reference (Dae Woo Lee, et al., SyntHetic Organic Chemistry, 2007, 37:5, 737-742). The general process is as follows: Add 30 mL of methanol to a 250 mL single-necked round bottom flask and place it in an ice-water bath, then add 8.2 mL of concentrated hydrochloric acid, stir for 10 minutes, and then transfer to room temperature for 15 minutes. Weigh 11.60g (0.100mol) of hexamethylenediamine and dissolve it in 30mL of methanol, add it into the reaction flask under stirring, first react in an ice-water bath for 15 minutes, transfer to room temperature and stir for 15 minutes, add 5mL of water and continue stirring fo...

Embodiment 3

[0100] Embodiment 3, the synthesis of diamine adduct crosslinking agent

[0101] (1) Preparation of 3-furylmethylamine of Boc-protection

[0102] The synthesis method is the same as in Example 1, except that the raw material furylmethylamine is replaced with 3-furylmethylamine.

[0103] (2) Preparation of N-substituted maleimides of Boc protected amino groups

[0104] The preparation method is the same as that in Example 2, except that the hexamethylenediamine used to prepare the Boc-protected amino N-substituted maleimide is replaced by 1,8-diamino-3,6-dioxahexane.

[0105] (3) Preparation of double-ended Boc-protected diamine Diels-Alder adducts

[0106] React the above prepared Boc-protected furanylamine and N-substituted maleimide of Boc-protected amino group in a molar ratio of 2:1 at 80°C for 24 hours, cool to room temperature, concentrate and wash with cold n-hexane several times , and dried to obtain a white solid which is the double-ended Boc-protected diamine Diel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com