Heat-conductive laminated material and manufacturing method thereof

A technology of laminate materials and thermal conductive layers, applied in chemical instruments and methods, layered products, semiconductor devices, etc., can solve the problem of poor contact tightness between thermally conductive pressure-sensitive adhesive tapes and adherends, difficulty in removing adhesive tapes, and damage to electronic products. components, etc., to achieve the effects of excellent reworkability, favorable thermal conductivity, and excellent handling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0166] The details of the present invention are described below using a series of examples and comparative examples, but the following examples do not limit the present invention in any way.

[0167] First, components (a) to (f) used in the following Examples and Comparative Examples are listed below.

[0168]

[0169] -(A-1) Dimethicone in which both molecular chain terminals are terminated with dimethylvinylsiloxy groups, having a kinematic viscosity at 25° C. of 600 mm 2 / sec

[0170] -(A-2) Dimethicone in which both molecular chain terminals are terminated with dimethylvinylsiloxy groups, having a kinematic viscosity at 25° C. of 30,000 mm 2 / sec

[0171]

[0172] -(B-1) Alumina powder with an average particle size of 10.7 microns (absolute specific gravity: 3.98)

[0173] -(B-2) Alumina powder with an average particle size of 1.1 microns (absolute specific gravity: 3.98)

[0174] -(B-3) Zinc oxide powder with an average particle size of 0.6 microns (absolute specifi...

preparation example 1 to 4

[0195] [Preparation Examples 1 to 4, Comparative Preparation Examples 1 to 4]

[0196]

[0197] The components shown in Table 1 below were mixed together in the blending amounts (parts by mass) shown in Table 1 using the method described below, thereby forming a series of compositions S1 to S7. Compositions S5, S6 and S7 do not meet the conditions of the present invention.

[0198] Component (a), component (b), and if used, component (g) and component ( h), and mix the components for 60 minutes. Subsequently, component (d) and component (e) were added, and the resulting mixture was thoroughly mixed. Finally, component (c) and component (f) are added, and the mixture is mixed well again to form a homogeneous composition.

[0199] [Table 1]

[0200]

[0201] (Note 1): The values in parentheses ( ) in this table represent parts by volume of the resin portion in component (f) per 100 parts by volume of component (a).

[0202] (Note 2): The concentration values of com...

Embodiment 1 to 4

[0204] [Examples 1 to 4, Comparative Examples 1 to 5]

[0205]

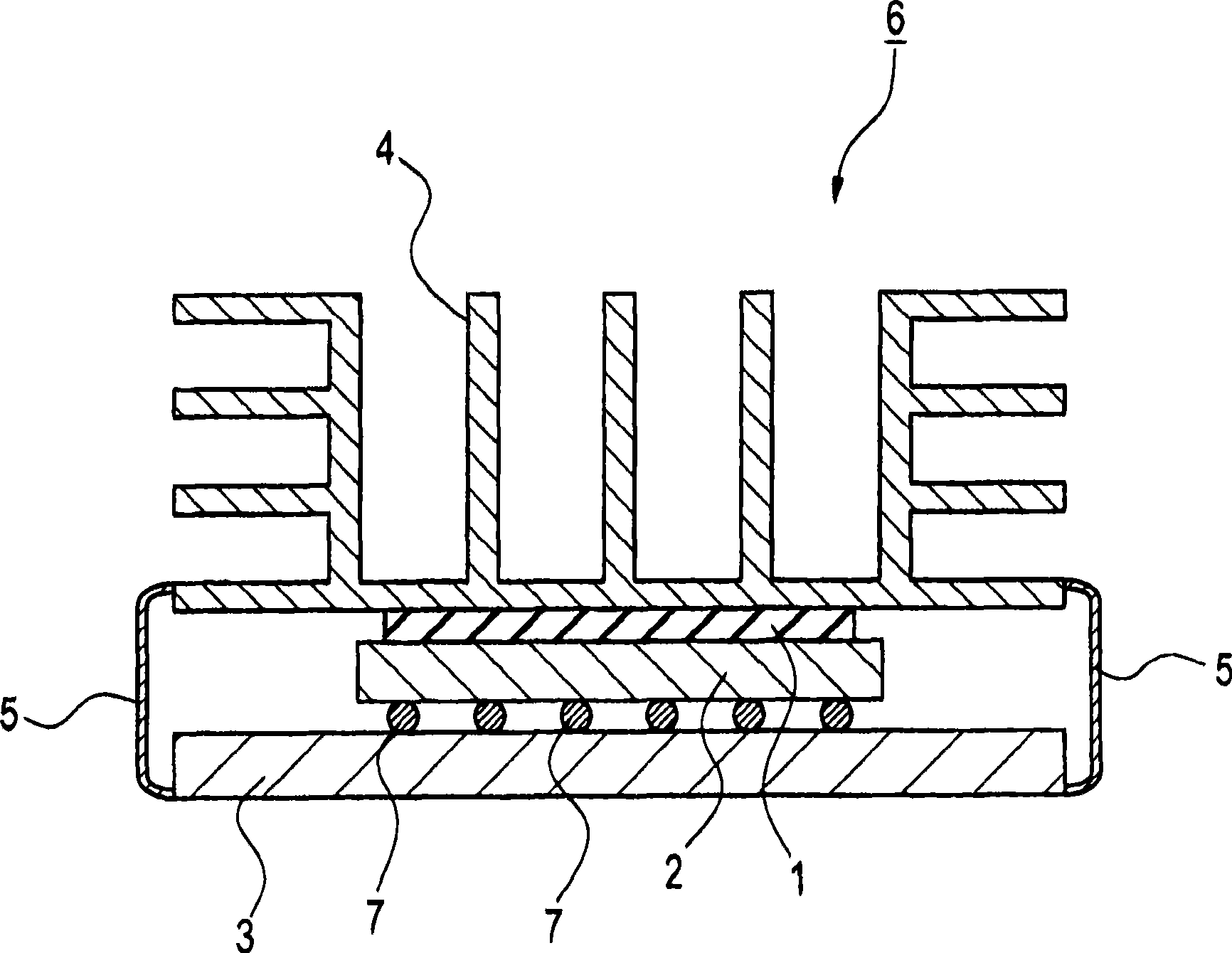

[0206] The laminates shown in Tables 2 and 3 below were produced in the following manner using the conditions shown in Tables 2 and 3. First, one of the compositions obtained in Table 1 (hereinafter referred to as composition X1) was selected, and this composition X1 was applied to a substrate and then cured to produce a single-layer thermally conductive cured product (Y1). Subsequently, another composition obtained in Table 1 (hereinafter referred to as composition X2) was selected, and this composition X2 was applied to the single-layer thermally conductive cured product Y1, followed by curing, resulting in a laminate (Y2).

[0207]Each of the laminates thus obtained was evaluated for tack, reworkability and selective releasability, oil bleed, release from the substrate, handling after peeling from the substrate, and thermal resistance. The results are shown in Table 2 and Table 3.

[0208] -Peelability

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com