Acrylic pressure-sensitive adhesive composition with good re-workability

An acrylic pressure-sensitive adhesive, acrylic copolymer technology, applied in the direction of film/sheet adhesive, adhesive type, ester copolymer adhesive, etc., can solve the problem of high peel strength, PDP filter No reworkability, durability, reliability, inapplicability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0086] Using the acrylic acid copolymer A shown in the following table 1 as the acrylic monomer composition, as shown in the following table 2, add 1.0 parts by weight of polyether modified polydimethylsiloxane copolymer (GE Toshiba Silicones L-7500 Silwet(R), after which the above-mentioned mixing and coating process and the preparation process of the PDP filter were carried out, and a peeling test and a durability test were carried out. The measurements of 180° peel strength, reworkability and durability are given in Table 3 below.

Embodiment 2

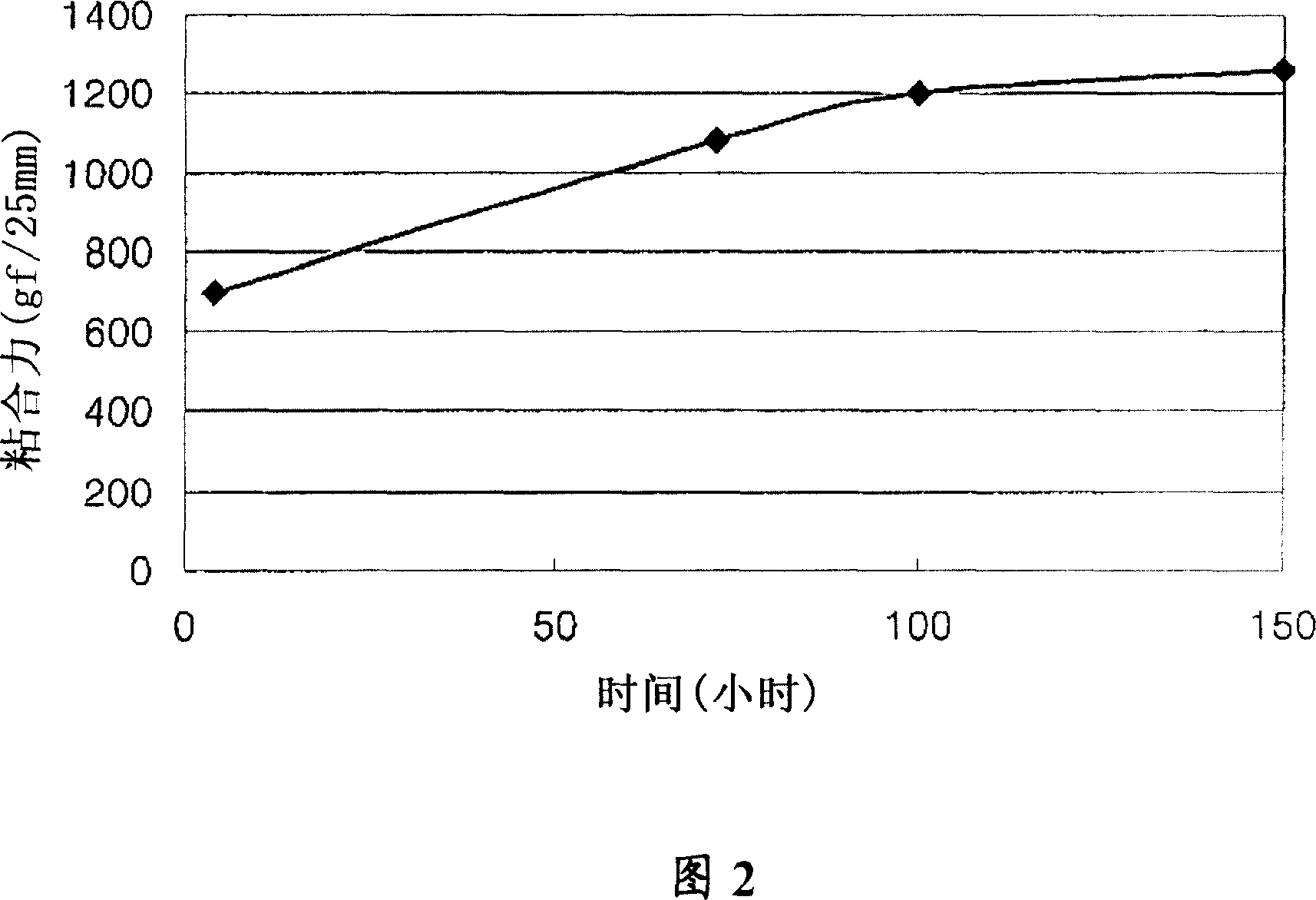

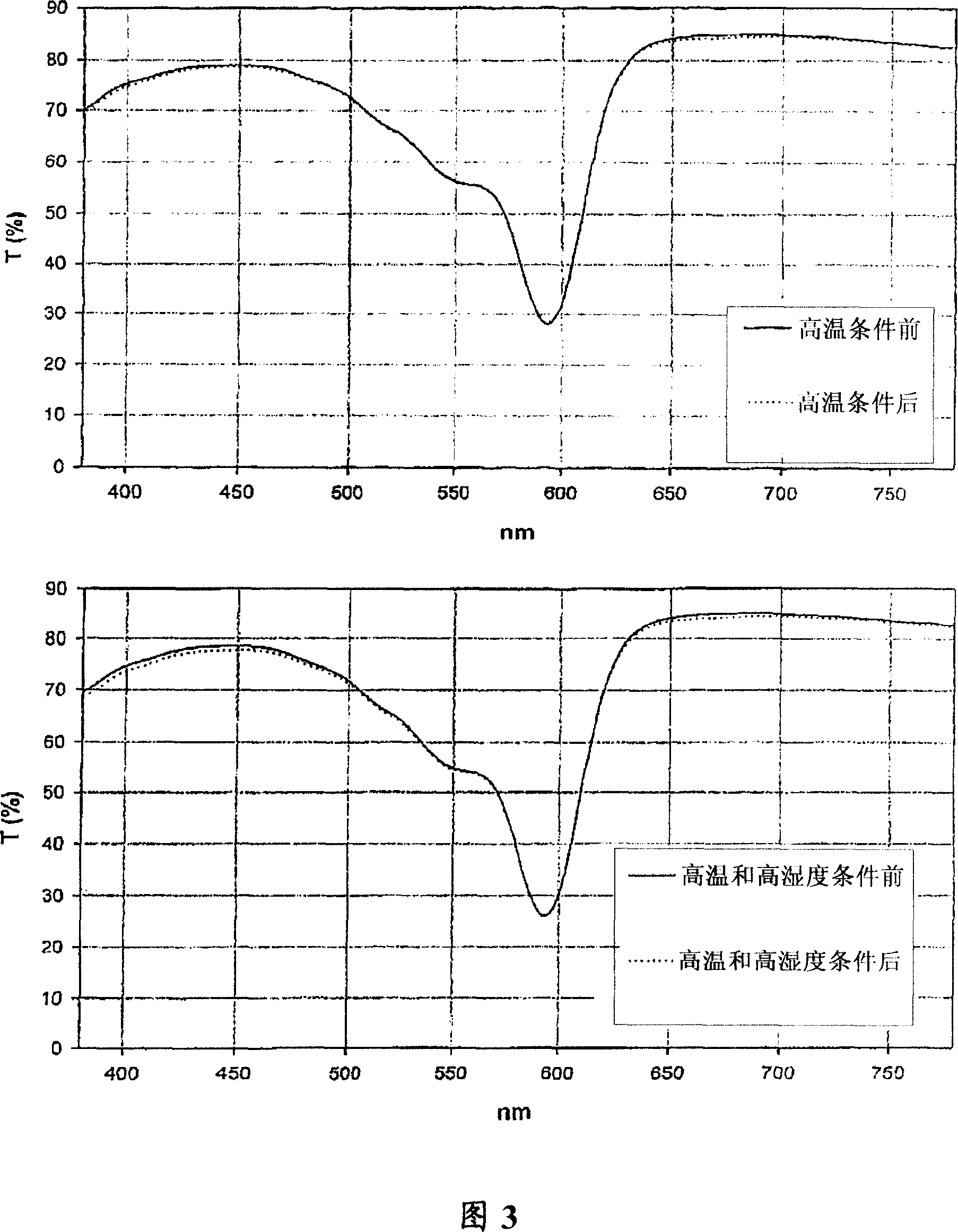

[0088] In addition to using the acrylic copolymer A shown in Table 1 below, as shown in Table 2 below, 0.1 parts by weight of a polyether-modified polydimethylsiloxane copolymer (GE Toshiba Silicones L-7500 Silwet(R)) having an HLB of 8 was added ), and 0.05 parts by weight of the porphyrin color compensation dye (Japan Yamada chemistry, TAP-2 level, porphyrazine dye), carry out the present embodiment in the same way as Example 1 (in the functional film layer No color compensation layer is used). The results for 180° peel strength, reworkability and durability are given in Table 3 below. In addition, in order to measure the change of adhesive force with time, each adhesive force of the PDP filter after intervals of 4 hours, 72 hours, 100 hours, and 150 hours was measured under the same conditions as measuring the initial adhesive force. Table 4 and Figure 2 below present the results. In addition, the results of the optical durability test are given in Table 5 below, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com