Self-repairing reprocessable polyurea material as well as preparation method and application

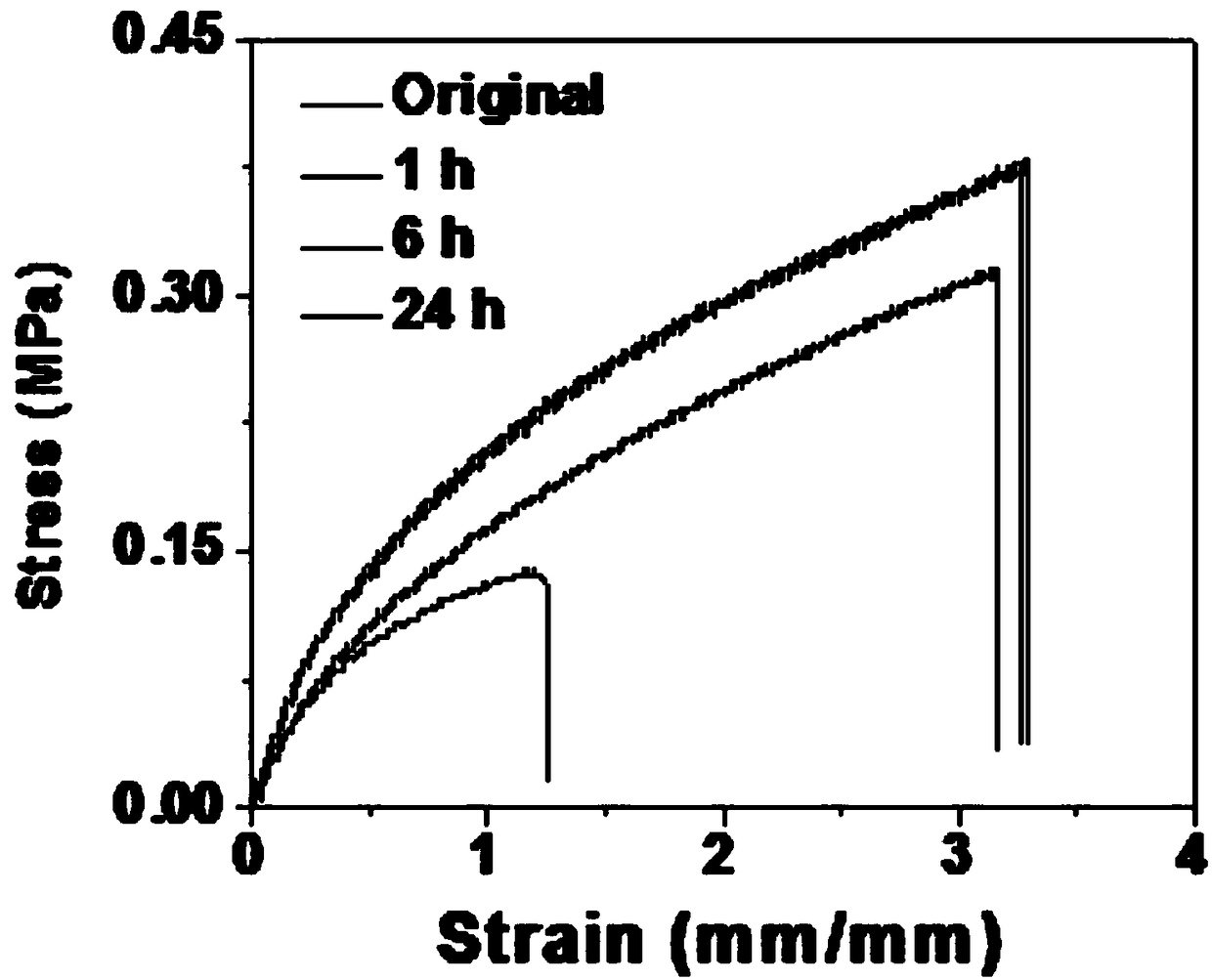

A repetitive processing and self-repairing technology, applied in polyurea/polyurethane coatings, additive processing, anti-corrosion coatings, etc., can solve problems such as storage difficulties and poor stability of polyurea, and achieve improved mechanical strength, good reprocessing performance, and self-healing The effect of high repair efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

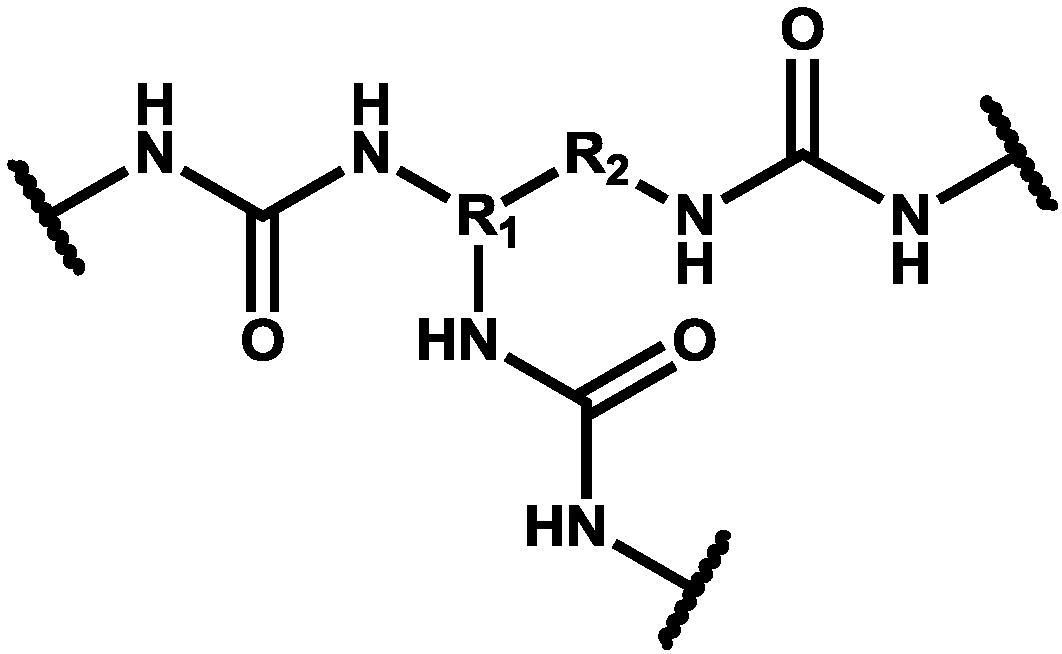

[0031] The amino-terminated polyetheramine is an amino-terminated polyetheramine with a molecular weight of 200-20000. The diisocyanate is any one of toluene diisocyanate, diphenylmethane diisocyanate, xylylene diisocyanate, hexamethylene diisocyanate, and dicyclohexylmethane diisocyanate. The crosslinking agent is hexamethylene diisocyanate trimer, toluene diisocyanate trimer, and diphenylmethane diisocyanate trimer. The catalyst is zinc acetate, trifluoromethanesulfonate (such as zinc trifluoromethanesulfonate, nickel trifluoromethanesulfonate, lanthanum trifluoromethanesulfonate, cerium trifluoromethanesulfonate, etc.), dibutyltin dilaurate , Stannous octoate, iron trichloride, cesium fluoride, ammonium fluoride, triethylamine, N,N-dimethylcyclohexylamine or any one of Lewis acid and Lewis base catalyst. The polyetheramine is an amino-terminated polyamide, an amino-terminated polysiloxane, an amino-terminated dihydrazide, an amino-terminated nylon, an amino-containing organ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com