Efficient antibacterial waterborne polyurethane floor coating and preparation method thereof

A technology for water-based polyurethane and floor coatings, applied in polyurea/polyurethane coatings, antifouling/underwater coatings, coatings, etc., can solve the problems of poor compatibility between antibacterial agents and water, difficulty and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

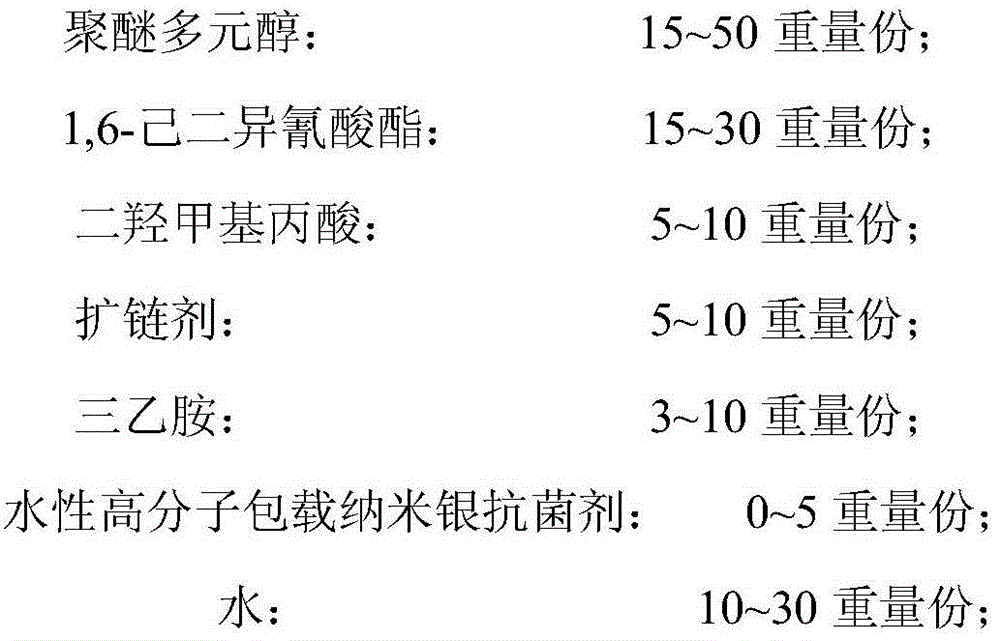

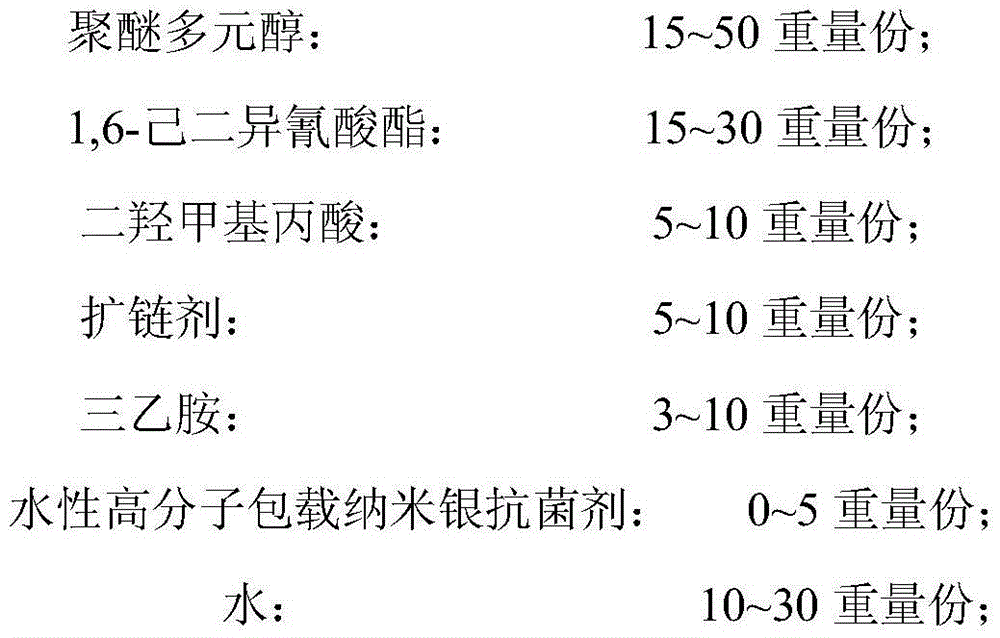

[0025] Preparation of component A: 25 parts by weight of polyethylene glycol ether and 25 parts by weight of 1,6-hexamethylene diisocyanate (HDI) are added to a three-necked flask equipped with a thermometer, a stirring device and a reflux condenser, and the Under protection, heat to 90°C for 2 hours, then add 5 parts by weight of dimethylolpropionic acid DMPA to react for 1 hour, finally add 7 parts by weight of chain extender diethyltoluenediamine, react at 60°C for 4 hours, and cool to 30°C Discharge, neutralize the prepolymer with triethylamine (TEA) to pH = 7, then add 2 parts by weight of water-based epoxy-coated silver-loaded (Ag / EP-PEG) antibacterial agent, 30 parts by weight of deionized water, high-speed Emulsified for 30 minutes to obtain a white emulsion.

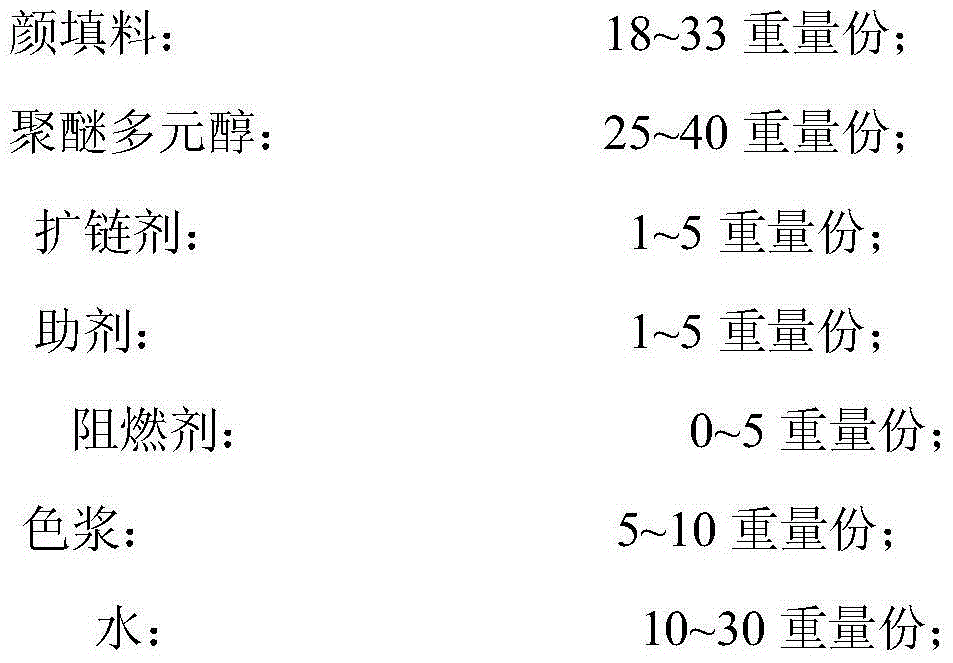

[0026] Preparation of component B: add 10 parts by weight of silicon micropowder, 8 parts by weight of titanium dioxide, 8 parts by weight of talcum powder, 30 parts by weight of polyethylene glycol ether, 25 pa...

Embodiment 2

[0029] Preparation of component A: 22 parts by weight of polypropylene glycol ether and 28 parts by weight of 1,6-hexamethylene diisocyanate (HDI) were added to a three-necked flask equipped with a thermometer, a stirring device and a reflux condenser, under nitrogen protection , heated to 90°C for 2 hours, then added 7 parts by weight of dimethylolpropionic acid DMPA to react for 1 hour, and finally added 4 parts by weight of chain extender dimethylmercaptotoluenediamine, reacted at 60°C for 3 hours, cooled to 30°C and discharged , neutralize the prepolymer with triethylamine (TEA) to pH = 7, then add 1 weight part of water-based epoxy-coated silver (Ag / EP-PEG) antibacterial agent, 30 weight parts of deionized water, and emulsify at high speed for 10 minutes A white emulsion was obtained.

[0030] Preparation of component B: add 8 parts by weight of silicon micropowder, 10 parts by weight of titanium dioxide, 10 parts by weight of talcum powder, 25 parts by weight of polypent...

Embodiment 3

[0033] Preparation of component A: 30 parts by weight of polycarbonate diol and 26 parts by weight of 1,6-hexamethylene diisocyanate (HDI) are added to a three-necked flask equipped with a thermometer, a stirring device and a reflux condenser. Under nitrogen protection, heat to 80°C for 3 hours, then add 5 parts by weight of dimethylolpropionic acid DMPA for 1 hour, finally add 5 parts by weight of chain extender 1,4-butanediol, react at 60°C for 5 hours, and cool to Discharge at 25°C, neutralize the prepolymer with triethylamine (TEA) to pH = 7, then add 1 part by weight of water-based epoxy-coated silver (Ag / EP-PEG) antibacterial agent, and 30 parts by weight of deionized water , high-speed emulsification for 30 minutes to obtain a white emulsion.

[0034] Preparation of component B: add 10 parts by weight of silicon micropowder, 8 parts by weight of titanium dioxide, 10 parts by weight of talcum powder, 25 parts by weight of polytetrahydrofuran ether glycol, 30 parts by wei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com