Method for preparing composite material of poly lacltic acid enhanced by ramie fiber

A technology of ramie fiber and composite materials, which is applied in fiber processing, plant fiber, textiles and papermaking, etc., can solve the problem of interface between hemp fiber and matrix resin, natural fiber and resin interface, Non-biodegradable and other problems, to achieve the effect of excellent interface properties and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

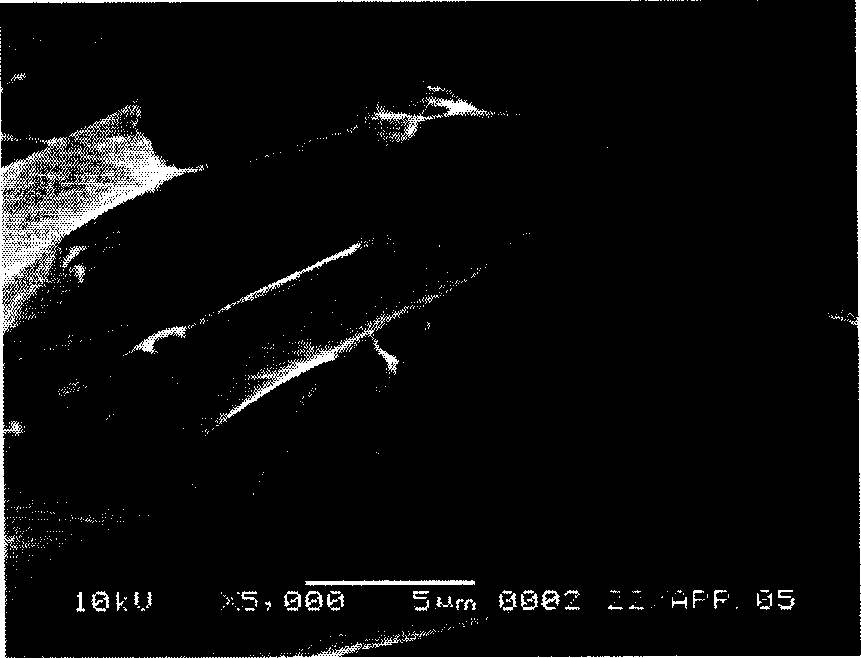

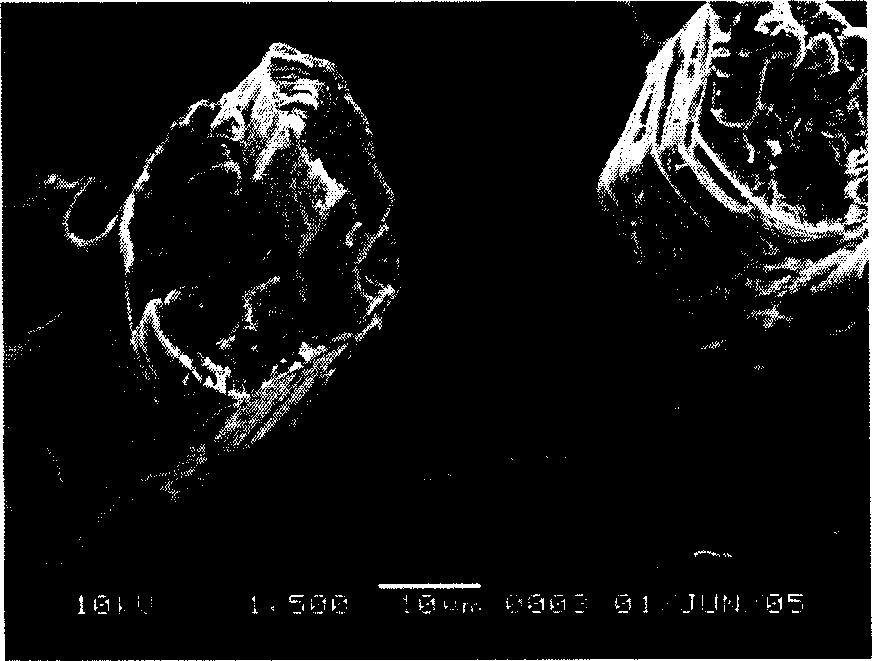

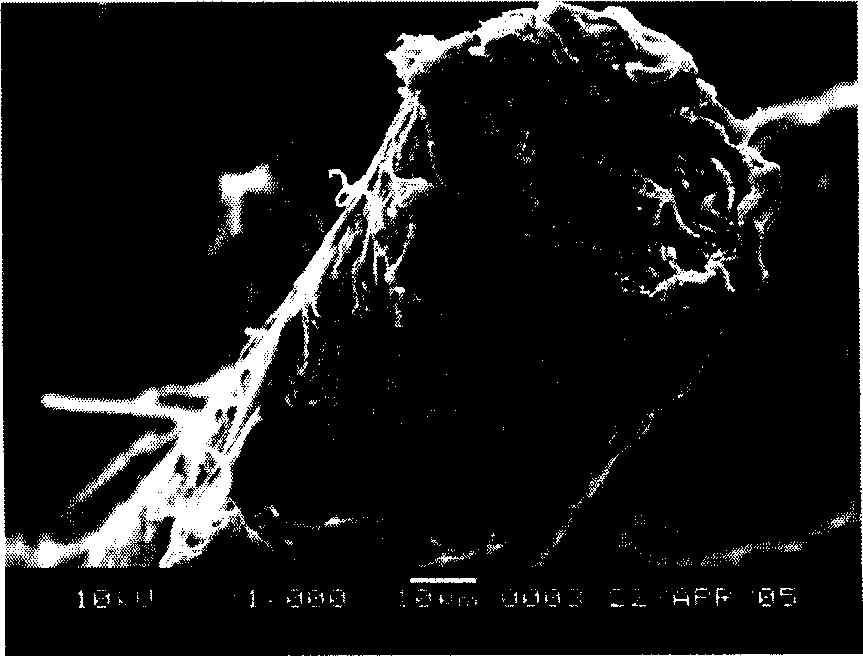

Image

Examples

Embodiment 1

[0022] Weigh respectively 42.0g of polylactic acid prepolymer (PLA) with a viscosity-average molecular weight of 25000 and 18.0g of polycaprolactone (PCL) with a viscosity-average molecular weight of 1000 (PLA / PCL=7: 3), and then prepare them respectively into a 0.1g / ml chloroform solution, then soak the dried KH550-treated ramie fibers in the PCL chloroform solution, and then pour them into a 1000ml glass reactor and seal them. React in a constant temperature water bath at 80° C. while stirring at a constant speed for 2 hours, and then distill the chloroform out under reduced pressure. In this way, a small amount of chloroform in the product is volatilized to obtain the ramie fiber reinforced PLA-PCL copolymer composite material. Then follow the same steps above to prepare reinforced PLA-PCL with untreated ramie and to prepare reinforced PLA-PCL composites with KH560-treated ramie fibers.

[0023] The above-prepared product was put into a mold and pressed at 150°C to form a ...

Embodiment 2

[0026] Weigh 42.0g of PLA with a viscosity-average molecular weight of 80,000 and 42.0g of gPCL (PLA / PCL=7:3) with a viscosity-average molecular weight of 400, and then prepare them into 0.1g / ml tetrahydrofuran solution, then dry the The ramie fibers with a length of 1mm were soaked in the chloroform solution of PCL, and then they were poured into a 1000ml glass reactor and sealed. React in a constant temperature water bath at 80° C. while stirring at a constant speed for 2 hours, and then distill THF under reduced pressure. In this way, a small amount of chloroform in the product is volatilized to obtain the ramie fiber reinforced PLA-PCL copolymer composite material. Then follow the same steps above to prepare ramie fiber reinforced PLA-PCL composites with fiber lengths of 5 mm and 30 mm, and mold the obtained products into standard specimens at 150 °C. The measured mechanical properties are shown in Table 2.

[0027]

Embodiment 3

[0029] Take by weighing 162.0g of PLA with a viscosity-average molecular weight of 1000 and 18.0g of gPCL (PLA / PCL=7:3) with a viscosity-average molecular weight of 2000, and then they are respectively made into 0.1g / ml acetone solution, and then the total Ramie fibers with a weight ratio of 15% were soaked in a chloroform solution of PCL, and then they were poured into a 1000ml glass reactor and sealed. React in a constant temperature water bath at 80° C. while stirring at a constant speed for 2 hours, and then distill out acetone under reduced pressure. In this way, a small amount of chloroform in the product is volatilized to obtain the ramie fiber reinforced PLA-PCL copolymer composite material. Then follow the same steps above to prepare ramie fiber-reinforced PLA-PCL composite materials with fiber content of 5%, 20%, 25%, and 80%, and then mold the product into a standard sample at 150°C to measure the mechanical properties As in Table 3.

[0030]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com