Degradable gas-phase fruit and vegetable preservative film and preparation method thereof

A gas-phase technology for fresh-keeping of fruits and vegetables, which is applied in the field of degradable gas-phase fresh-keeping film for fruits and vegetables and its preparation, can solve the problems that the fresh-keeping effect is not obvious, the materials and processes are not the same, and it is difficult to industrialize production. Easy promotion and stable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

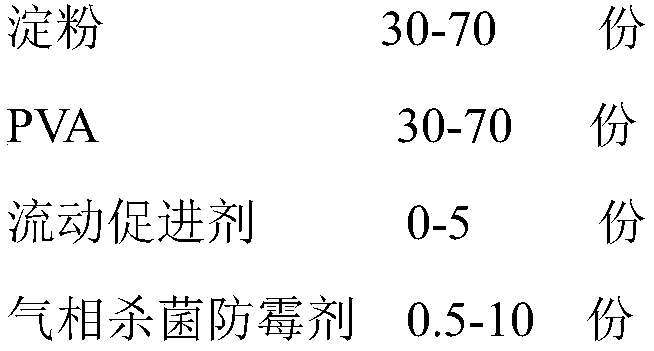

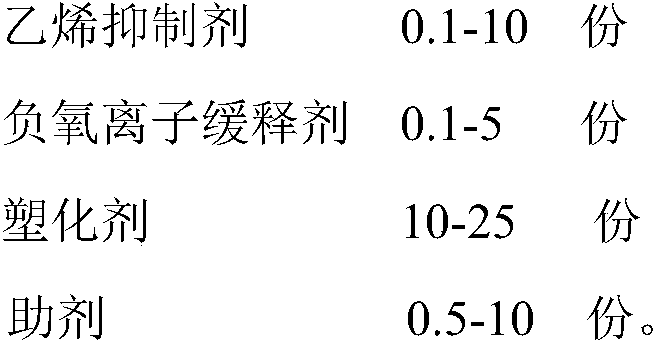

Method used

Image

Examples

Embodiment 1

[0041] 50 parts of corn starch, 50 parts of PVA 1799, 1.5 parts of flow promoter, 1.5 parts of dimethyl fumarate, 0.5 parts of J-100, 1.0 parts of nano-silver ion titanium dioxide, 1.5 parts of tourmaline, 0.3 parts of graphene oxide, 20 parts of plasticizer, 3 parts of additives, 1.5 parts of activated carbon. Weigh it according to the proportion, place it in a high-speed mixer and heat it while stirring, mix at 45-120°C / 30-45 minutes, cool to room temperature, place it in a natural state for 12-24 hours, and then granulate it through a twin-screw granulator , the temperature is controlled within the range of 120-180°C, and then the film is blown.

[0042] The synthetic method of described flow accelerator is as follows:

[0043] Heat and melt 30 parts of polyvinyl acetate, 30 parts of polyvinyl alcohol 0588, 10 parts of glyceryl monoacetate, 10 parts of glyceryl diacetate, 10 parts of glyceryl triacetate and 10 parts of glycerin, and stir evenly to obtain the obtained desc...

Embodiment 2

[0049] 50 parts of tapioca starch, 50 parts of PVA 1799, 1.8 parts of flow promoter (see Example 1 for synthetic method), 1.0 part of dimethyl fumarate, 0.5 part of nano-silver ion zeolite, 1.5 parts of tourmaline, 20 parts of plasticizer , 2.5 parts of auxiliary agents (see Example 1 for the synthetic method), and 1.5 parts of molecular sieves. After weighing according to the proportion, put it in a high-speed mixer and heat it while stirring, mix it at 45-120°C / 30-45 minutes, cool it to room temperature, put it in a natural state for 12-24 hours, and then process it through a twin-screw granulator Granules, the temperature is controlled within the range of 80-180°C, and then the film is blown.

[0050] The synthetic method of described plasticizer is as follows:

[0051] 30 parts of glycerol, 5 parts of glycerol triacetate, 5 parts of ethylene glycol, 10 parts of deionized water, and 5 parts of ethyl acetate and ethylenediamine reactants are mixed evenly.

Embodiment 3

[0053] 50 parts of potato starch, 50 parts of PVA 1799, 1.5 parts of flow enhancer (see Example 1 for the synthetic method), 3 parts of J-1003, 2 parts of 3.3-dimethylcyclopropene, 0.3 part of nano-silver ion titanium dioxide, 1.2 parts of medical stone 2 parts, 2 parts of activated carbon, 25 parts of plasticizer, 2.5 parts of additives (see Example 1 for the synthesis method), weighed in proportion and put into a high-speed mixer while stirring and heating, at 45-120°C / 30-45 minutes Mix, cool to normal temperature, place in the natural state for 12-24 hours, then granulate through a twin-screw granulator, control the temperature within the range of 80-180°C, and then blow the film.

[0054] The synthetic method of described plasticizer is as follows:

[0055] Mix 30 parts of glycerol, 15 parts of propylene glycol, 5 parts of polyethylene glycol, 5 parts of the reaction product of ethyl acetate and triethanolamine, and 10 parts of deionized water until uniform.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com