Preparation method of reinforced polylactic acid composite material for ramie-fabric

A composite material and fabric reinforcement technology, used in textiles, papermaking, fiber processing, etc., can solve the problems of interface problems that have not been well solved and cannot be solved, and achieve the effect of excellent interface properties and mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

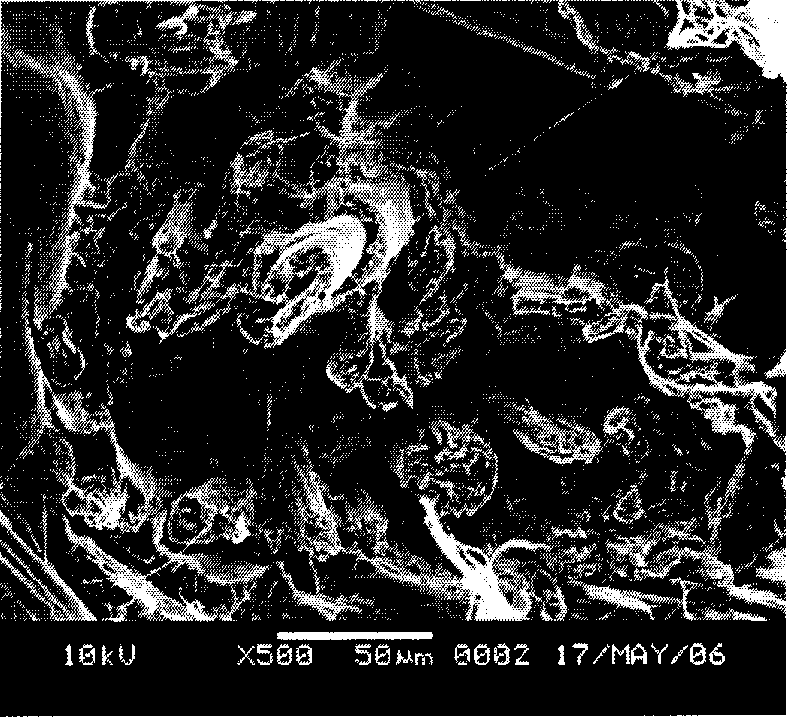

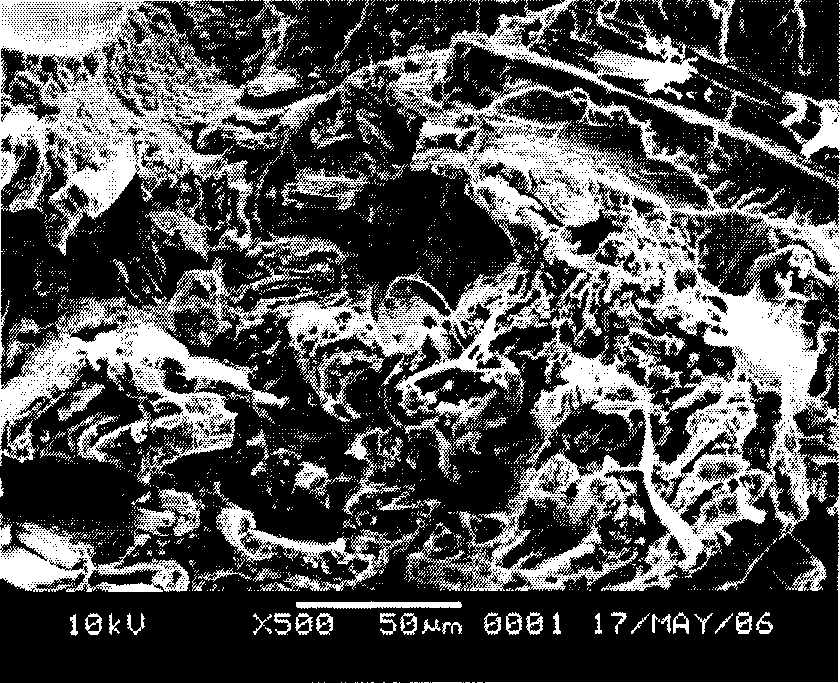

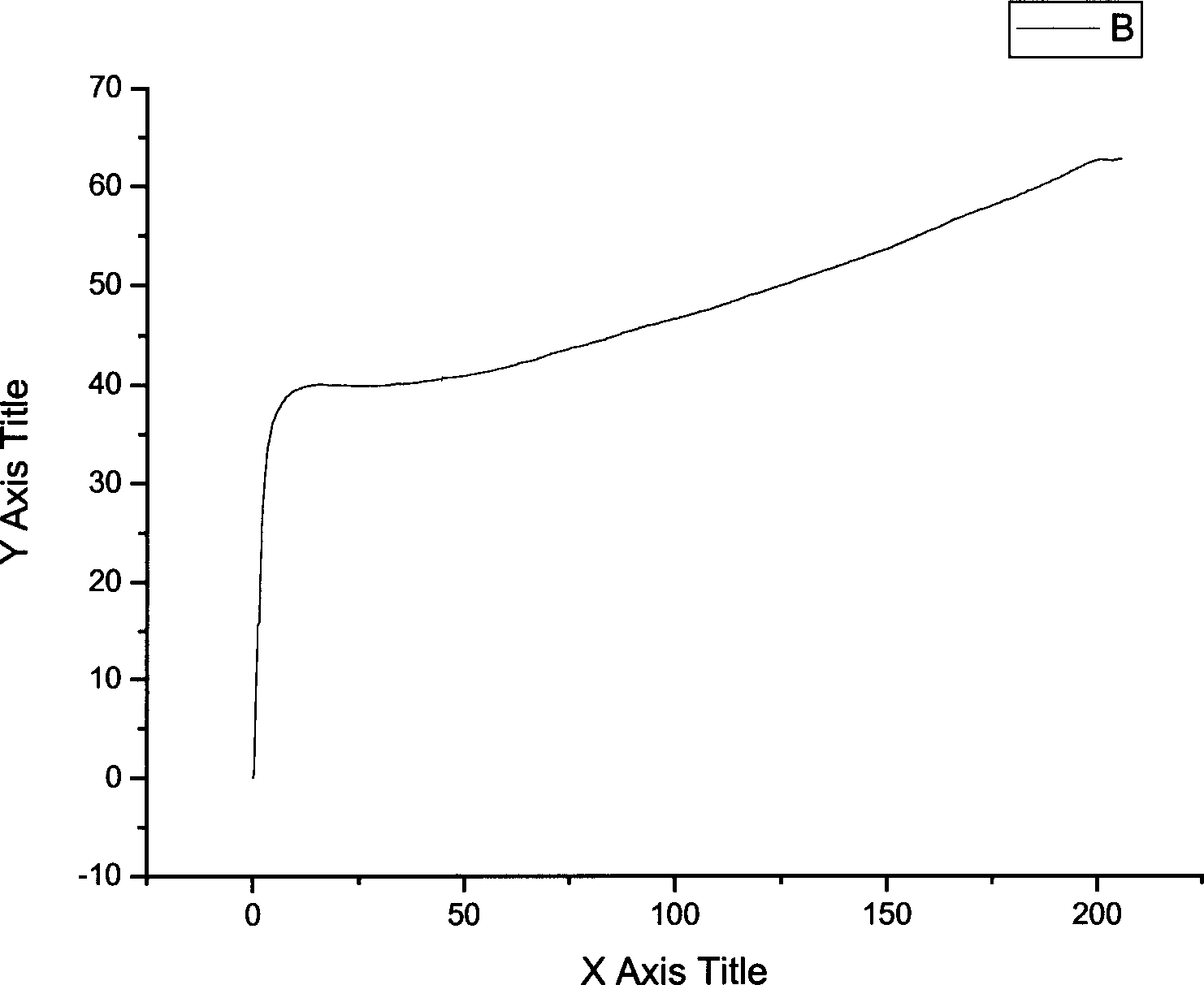

Image

Examples

Embodiment 1

[0024] Weigh polylactic acid (PLLA) with a viscosity-average molecular weight of 27,000 and polycaprolactone (PCL) with a viscosity-average molecular weight of 1000 with a weight ratio of 7:3, and make them into 0.1g / ml chloroform solutions respectively, and then KH550-treated ramie fabrics accounting for 45% by weight of the total were soaked in a chloroform solution of PCL, and then they were poured into a 1000 ml glass reactor and sealed. Magnetic stirring was carried out in a constant temperature water bath at 80°C for 4 hours, and the prepreg layer was laminated into a sample strip.

[0025] Tensile

Embodiment 2

[0027] Take by weighing the PLLA that the viscosity-average molecular weight of 1:1 is 1000 and the PCL that the viscosity-average molecular weight is 2000, they are respectively made into the acetone solution of 0.1g / ml, will account for the ramie fabric of 35% of gross weight afterwards soak in PCL in acetone solution, and then pour them into a 1000ml glass reactor and seal it well. Magnetically stir the reaction in a constant temperature water bath at 60°C for 4 hours, pour out the product, evaporate the solvent, and place it in a vacuum oven for 24 hours to obtain a prepreg. According to the above method, the fabric content is respectively 45%, 55%, 65%, and 75% ramie fabric reinforced PLA-PCL composite material, and then laminated into standard splines at 170 ° C on a flat vulcanizer. The measured mechanical properties are as follows: Table 2.

[0028] fabric

Embodiment 3

[0030] Weigh PLLA with a viscosity-average molecular weight of 80,000 and a viscosity-average molecular weight of 400 with a weight ratio of 9:1, and make them respectively into 0.1 g / ml tetrahydrofuran solution, and then account for 75% of the total weight of KH560. The ramie fabrics were soaked in the tetrahydrofuran solution of PCL, and then they were poured into a 1000ml glass reactor and sealed well. Magnetic stirring was carried out in a constant temperature water bath at 90°C for 4 hours, and the prepreg layer was laminated into a sample strip.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com