Bone repair composite material based on acellular biological tissue matrix material and preparation method of bone repair composite material

一种生物组织基质、复合材料的技术,应用在骨修复用复合材料及其制备领域,能够解决无法满足信号通路需求、丧失生物学性能、提取过程复杂等问题,达到良好骨诱导性及成骨性、完全生物可降解性、优异骨传导性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

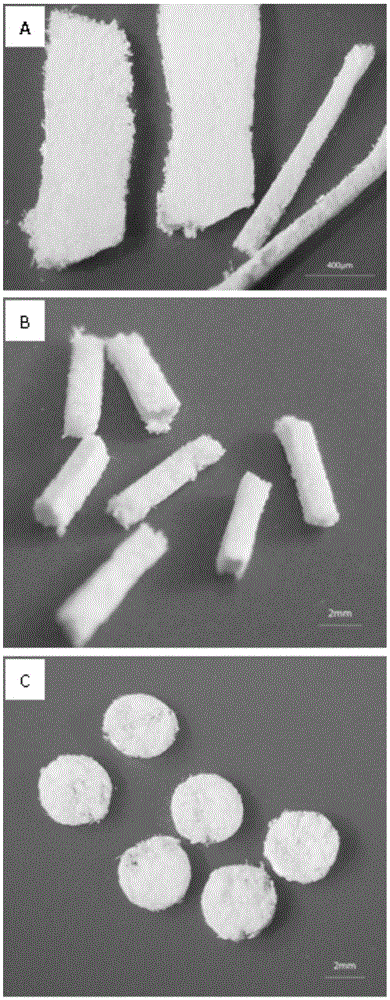

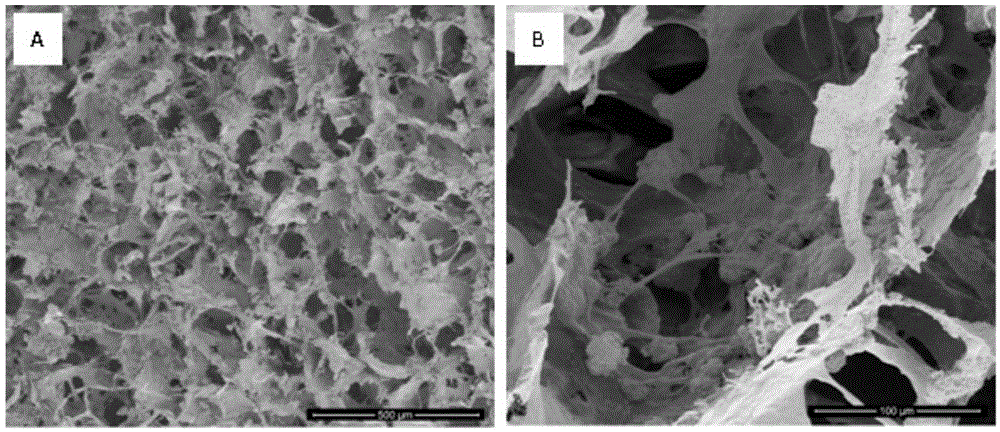

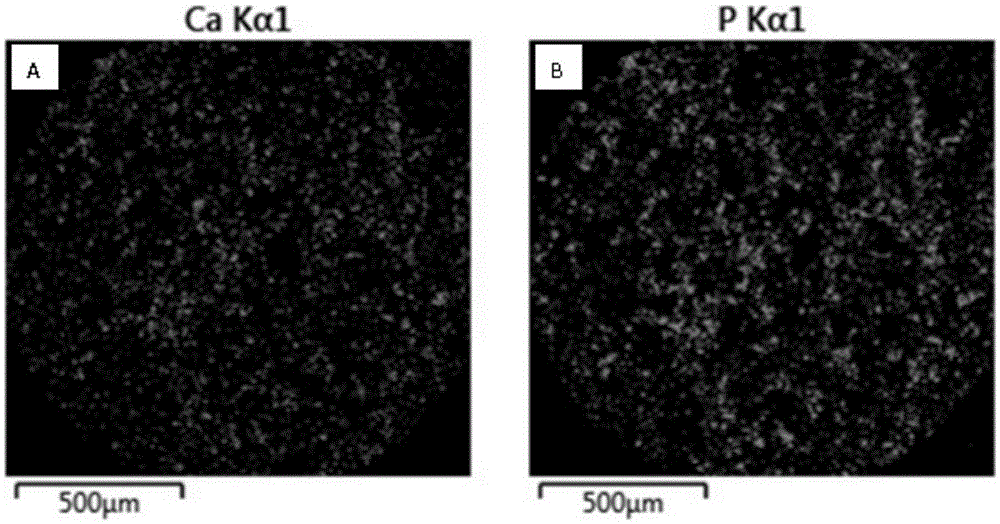

[0054]Get 240 mg of microfibrous biological tissue matrix material after decellularization of pigskin sterilized by gamma rays, add 1 milliliter of deionized water filtered by 0.22 μm PVDF membrane to the biological matrix microfiber material, and use a test tube shaker (vortexmixer) Disperse the microfiber biomatrix evenly in water. In addition, weigh 360 mg of powdered calcium hydrogen phosphate with a particle size of about 25 μm, add 1 ml of deionized water filtered by a 0.22 μm PVDF membrane, and disperse the calcium hydrogen phosphate evenly in the water with a test tube shaker (vortex mixer). Then 1 milliliter of microfiber biomatrix suspension is mixed with 1 milliliter of calcium hydrogen phosphate suspension, and the microfiber biomatrix and calcium hydrogen phosphate are mixed homogeneously with a homogenizer (calcium hydrogen phosphate weight ratio is 60% in the composite material) . The uniformly mixed microfibrous biomatrix and calcium hydrogen phosphate paste w...

Embodiment 2

[0057] Get 240 mg of microfibrous biological tissue matrix material after decellularization of pigskin sterilized by gamma rays, add 1 milliliter of deionized water filtered by 0.22 μm PVDF membrane to the biological matrix microfiber material, and use a test tube shaker (vortexmixer) Disperse the microfiber biomatrix evenly in water. In addition, weigh 103 mg of powdered calcium hydrogen phosphate with a particle size of about 25 μm, add 1 ml of deionized water filtered by a 0.22 μm PVDF membrane, and disperse the calcium hydrogen phosphate evenly in the water with a test tube shaker (vortex mixer). Then 1 milliliter of microfiber biomatrix suspension is mixed with 1 milliliter of calcium hydrogen phosphate suspension, and the microfiber biomatrix and calcium hydrogen phosphate are mixed homogeneously with a homogenizer (calcium hydrogen phosphate weight ratio is 30% in the composite material) . The uniformly mixed microfibrous biomatrix and calcium hydrogen phosphate paste ...

Embodiment 3

[0060] Get 240 mg of microfibrous biological tissue matrix material after decellularization of pigskin sterilized by gamma rays, add 1 milliliter of deionized water filtered by 0.22 μm PVDF membrane to the biological matrix microfiber material, and use a test tube shaker (vortexmixer) Disperse the microfiber biomatrix evenly in water. In addition, weigh 720 mg of powdered calcium hydrogen phosphate with a particle size of about 25 μm, add 1 ml of deionized water filtered by a 0.22 μm PVDF membrane, and disperse the calcium hydrogen phosphate evenly in the water with a test tube shaker (vortex mixer). Then 1 milliliter of microfiber biomatrix suspension was mixed with 1 milliliter of calcium hydrogen phosphate suspension, and the microfiber biomatrix and calcium hydrogen phosphate were mixed homogeneously with a homogenizer (calcium hydrogen phosphate weight ratio is 75% in the composite material) . The uniformly mixed microfibrous biomatrix and calcium hydrogen phosphate past...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com