Biodegradable modified polylactic acid material and preparation method thereof and method for preparing non-woven fabric by same

A polylactic acid material, biodegradable technology, applied in the direction of non-woven fabrics, textiles and papermaking, etc., can solve the problems of difficult prediction of biodegradability, performance requirements, physical and chemical properties, etc., to achieve comprehensive excellent degradation performance, preparation The process is environmentally friendly and the effect of easy implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] (1) Ingredients and composition: take by weight 100 parts of polylactic acid resin (produced by Nature Work, model 3051D), polyadipate-terephthalate-butylene glycol ester resin (PBAT) (produced by BASF company, Melting point Tm=110℃, glass transition temperature Tg=-30℃) 20 parts, inorganic filler (talc, 5000 mesh) 5 parts, plasticizer (acetylated tributyl citrate) 5 parts, functional additive stearin 0.5 part of zinc acid.

[0041] (2) Pretreatment of raw materials:

[0042] ①Drying: In a vacuum oven, the drying temperature of PLA and inorganic fillers is 80°C and the drying time is 5 hours, and the drying temperature of PBAT is 60°C and the drying time is 4 hours;

[0043] ②Mixing of raw materials: at room temperature, mix the raw materials prepared according to the pre-determined ratio in a mixer until uniform;

[0044] (3) Twin-screw extrusion granulation:

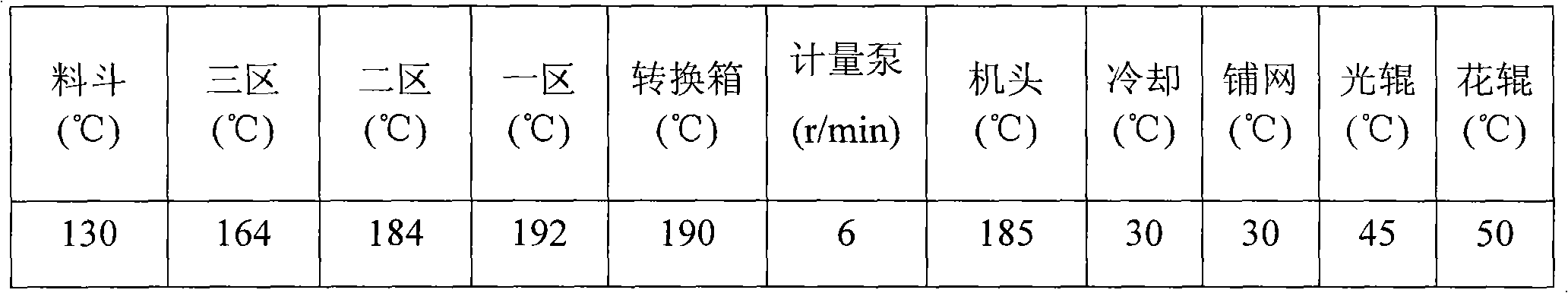

[0045] ①The twin-screw extruder controls the reactive extrusion according to the following 7-stage tempera...

Embodiment 2

[0051] (1) Ingredients and composition: weigh 100 parts of polylactic acid resin (produced by Nature Work, model 3051D), polyglutaric acid-ethylene terephthalate (PEGT) (produced by Far East Textile Co., Ltd.) by weight , melting point Tm=140℃, glass transition temperature Tg=-27℃) 30 parts, inorganic filler (talc, 5000 mesh) 10 parts, plasticizer (acetylated tributyl citrate) 5 parts, functional additives hard Zinc fatty acid 0.5 part, isocyanate 0.5 part.

[0052] Other steps and process conditions are the same as in Example 1.

[0053] The various test data of the non-woven fabrics of Examples 1 and 2 all meet or exceed the indicators in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com