Conductive slurry for solar battery and preparation method

A technology of solar cells and conductive pastes, applied in circuits, electrical components, semiconductor devices, etc., can solve the problems of unsatisfactory photoelectric conversion efficiency of solar cells, and achieve excellent mesh performance, uniform appearance and texture, and small bending degree Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

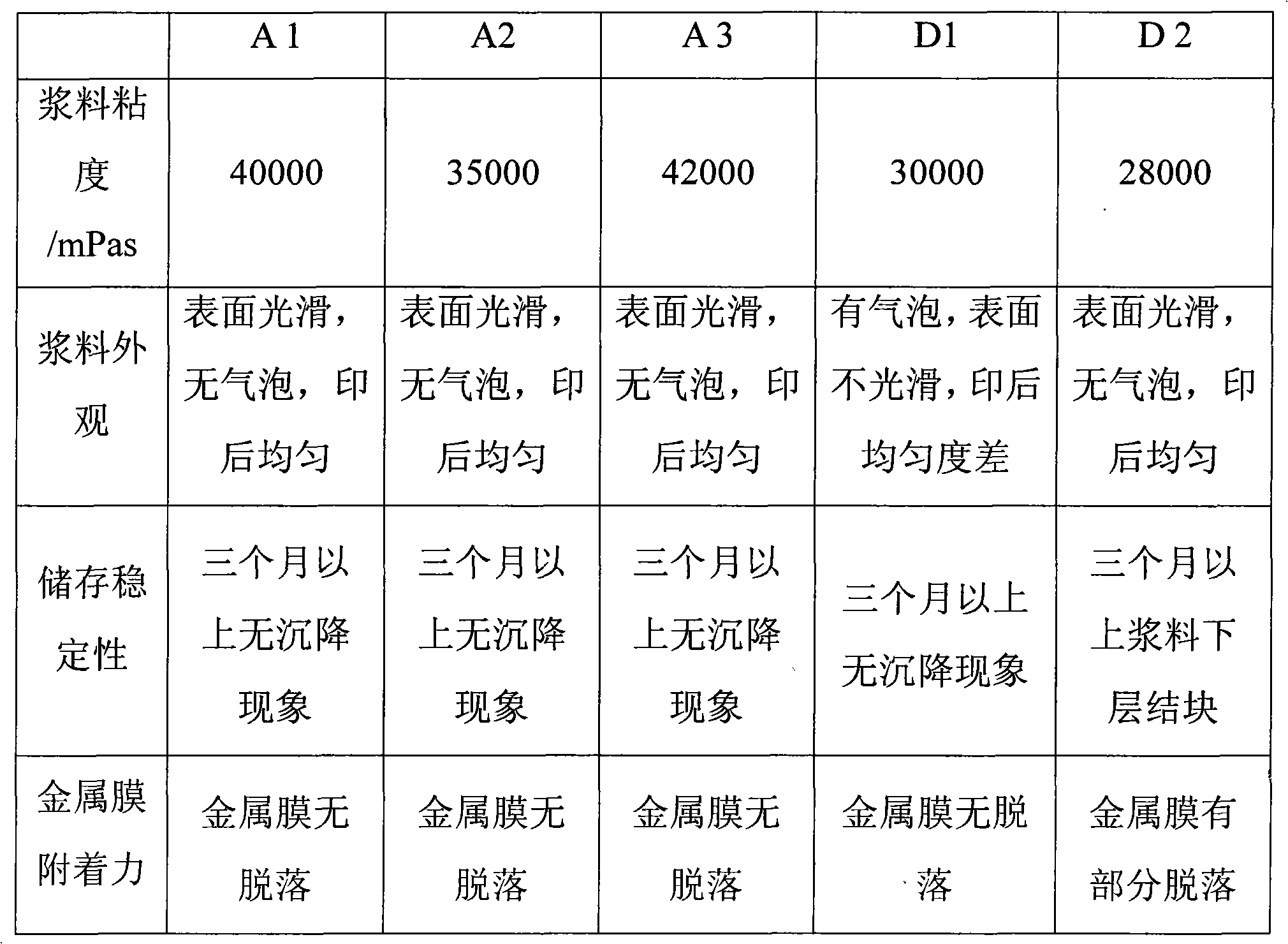

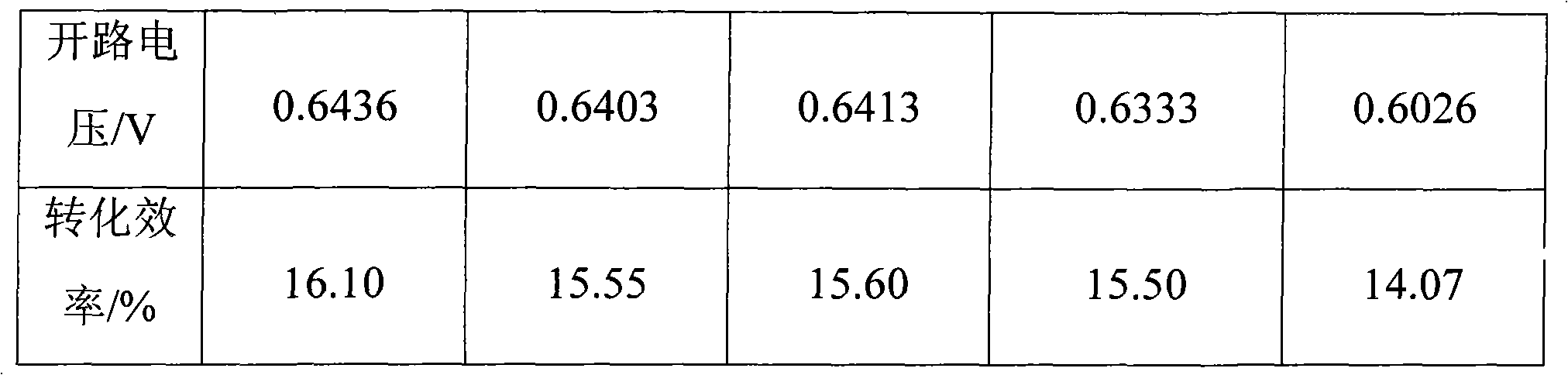

Examples

Embodiment 1

[0019] Step 1: Preparation of glass powder

[0020] Get 65wt% bismuth oxide (Bi 2 o 3 ) (oxides are all purchased from Tianjin Kemiou Chemical Reagent Co., Ltd., analytically pure, the same below), 12wt% boron oxide (B 2 o 3 ), 8.0wt% of silicon dioxide (SiO 2 ), 10wt% zinc oxide (ZnO), 3.0wt% aluminum oxide (Al 2 o 3 ), 2.0wt% magnesium oxide (MgO) was evenly mixed with a V-type mixer, put into a porcelain crucible, put into a silicon carbide rod furnace, heat up to 500°C, keep it warm for 0.5 hours, then rise to 950°C, and smelt After 0.5 hour, quench and filter with water, put the obtained glass beads into a ball mill tank, control the mass ratio, zirconia ball: glass beads: deionized water = 4:1:0.5, tank speed 150-250r / min, ball mill for more than 48h, filter , dried to obtain the medium particle size D 50 The glass powder at 0.2μm is ready for use.

[0021] Step 2: Configuration of organic carrier

[0022] Get terpineol according to mass ratio (organic solvent i...

Embodiment 2

[0026] Step 1: Preparation of glass powder

[0027] Same as Example 1.

[0028] Step 2: Configuration of organic carrier

[0029] Same as Example 1.

[0030] Step 3: Preparation of conductive paste

[0031] Change the large particle size aluminum powder into aluminum powder with a particle size of 6 μm, and change the small particle size aluminum powder into aluminum powder with a particle size of 35 nm. The rest is the same as step 3 of Example 1 to obtain the finished aluminum conductive paste A2.

Embodiment 3

[0033] Step 1: Preparation of glass powder

[0034] Same as Example 1.

[0035] Step 2: Configuration of organic carrier

[0036] Same as Example 1.

[0037] Step 3: Preparation of conductive paste

[0038] Change the aluminum powder with large particle size to aluminum powder with a particle size of 6 μm, and the aluminum powder with small particle size to aluminum powder with a particle size of 10 nm. The rest is the same as Step 3 of Example 1 to obtain the finished aluminum conductive paste A3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com