Glass silica gel Fresnel lens and manufacture method thereof

A technology of Fresnel lens and manufacturing method, which is applied in the direction of lens, optics, instruments, etc., can solve the problems of secondary foaming, difficulty in effectively removing air bubbles, and affecting the light-gathering effect of Fresnel lens, so as to improve production efficiency , The effect of shortening the curing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

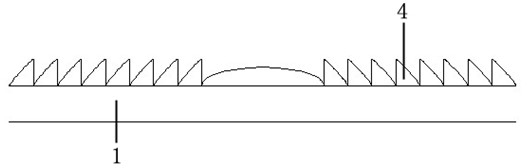

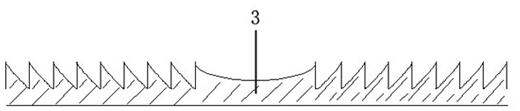

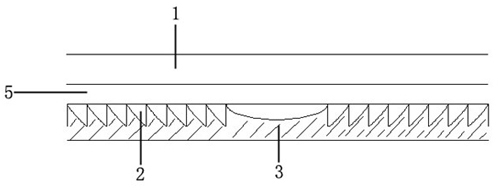

[0021] [Example 1] The process flow of the glass silica gel Fresnel lens manufacturing method is as follows: figure 2 As shown, first the adhesive is evenly coated on the tempered ultra-clear glass 1, and the release agent is evenly coated on the Fresnel lens mold 3; then use silica gel 2 (in this embodiment, the silica gel 2 has a transparency of 92 % more than pure silica gel) evenly spread on the Fresnel lens mold 3; before vacuuming, leave a certain volume of vacuum cavity 5 between the tempered ultra-clear glass 1 and the Fresnel lens mold 3, such as image 3 Shown; Start to vacuumize afterwards, when the degree of vacuum is 0.05Pa, the tempered ultra-clear glass 1 and the Fresnel lens mold 3 will be molded together, the mold clamping pressure is 50 kg / cm2, and the temperature will be lowered after the mold clamping. Heating to 90°C for curing; after curing for 24 minutes under the condition that the vacuum degree, clamping pressure and heating temperature are kept c...

Embodiment 2

[0022] [Example 2] The process flow of the glass silica gel Fresnel lens manufacturing method is as follows: as figure 2 As shown, first the adhesive is evenly coated on the tempered ultra-clear glass 1, and the release agent is evenly coated on the Fresnel lens mold 3; then use silica gel 2 (in this embodiment, the silica gel 2 has a transparency of 92 % more than pure silica gel) evenly spread on the Fresnel lens mold 3; before vacuuming, leave a certain volume of vacuum cavity 5 between the tempered ultra-clear glass 1 and the Fresnel lens mold 3, such as image 3 Shown; Start to vacuumize afterwards, when the degree of vacuum is 0.06Pa, the toughened ultra-white glass 1 and the Fresnel lens mold 3 are molded together, the mold clamping pressure is 100 kg / cm2, and the temperature is adjusted after the mold clamping. Heating to 96°C for curing; after curing for 22 minutes in an environment where the vacuum degree, clamping pressure and heating temperature are kept constant,...

Embodiment 3

[0023] [Example 3] The process flow of the glass silica gel Fresnel lens manufacturing method is as follows: as figure 2 As shown, first the adhesive is evenly coated on the tempered ultra-clear glass 1, and the release agent is evenly coated on the Fresnel lens mold 3; then use silica gel 2 (in this embodiment, the silica gel 2 has a transparency of 92 % more than pure silica gel) evenly spread on the Fresnel lens mold 3; before vacuuming, leave a certain volume of vacuum cavity 5 between the tempered ultra-clear glass 1 and the Fresnel lens mold 3, such as image 3 Shown; Start to vacuumize afterwards, when the degree of vacuum is 0.08Pa, the tempered ultra-clear glass 1 and the Fresnel lens mold 3 will be molded together, the mold clamping pressure is 200 kg / cm2, and the temperature will be lowered after the mold clamping. Heating to 100°C for curing; after curing for 20 minutes in an environment where the vacuum degree, clamping pressure and heating temperature are kept c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transparency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com