High-toughness and high-thermal-conductivity polymer material and preparation method thereof

A polymer material and high thermal conductivity technology, which is applied in the fields of polymer materials and their preparation, high toughness and high thermal conductivity polymer materials and their preparation, can solve the problem that thermally conductive plastics cannot meet the processing performance requirements of polymer materials and affect the scale of thermally conductive plastics Use, reduce the mechanical properties of composite materials and other issues, achieve good surface quality and mechanical properties, avoid stress cracking, and improve the effect of interface properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

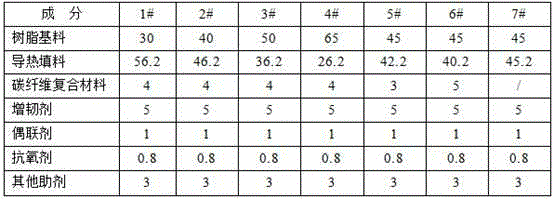

[0035] Example 1 According to the formula in Table 1, 6 different formula products (1#~6# in Table 1) were produced, and compared with the products produced by the formula (7#) without adding carbon fiber composite materials. The physical property measurement results of 7 different products produced according to the formula in Table 1 are shown in Table 2. The results show that the high toughness and high thermal conductivity polymer material obtained by the method of the present invention has mechanical properties such as bending strength and elongation at break and It has a better effect in terms of heat conduction effect.

[0036] Table 1 Product formula table (unit: parts by weight)

[0037]

[0038] In the above formula, the specific ingredients adopted are as follows:

[0039] (1) Resin base material: translucent or opaque milky white granular polycaprolactam with a relative viscosity of 2.8;

[0040] (2) Thermally conductive filler: whisker-shaped thermally conduct...

Embodiment 2

[0057] Embodiment 2 The following formula and steps are used to realize the preparation of the high toughness and high thermal conductivity polymer material thermal conductive plastic of the present invention.

[0058] 1. Formula: 55 parts of resin base material (polycaprolactam, compounded with industrial liquid crystal polymer and polypropylene at 2:1:1), 4 parts of carbon fiber composite material (microcrystalline graphite), thermally conductive filler (zinc oxide whisker and Zinc oxide particles are compounded with talcum powder, aluminum oxide, silicon oxide, zinc oxide, magnesium oxide, calcium oxide, aluminum nitride, boron nitride, silicon carbide) in a mass ratio of 1:1) 16 parts, toughening agent (maleic anhydride Grafted SEBS) 0.5 parts, coupling agent (3-glycidyl ether oxypropyltrimethoxysilane) 3 parts, antioxidant (antioxidant 1010) 2 parts, processing aid (release agent) 1 part .

[0059] 2. Preparation steps:

[0060] (1) After atomizing 3-glycidyl etheroxypr...

Embodiment 3

[0068] Embodiment 3 The following formula and steps are used to realize the preparation of the high toughness and high thermal conductivity polymer material thermal conductive plastic of the present invention.

[0069] 1. Formula: 35 parts of resin base material (polyhexamethylene adipamide, polyphenylene sulfide, acrylonitrile-butadiene-styrene copolymer, compounded according to 1:1:1), carbon fiber composite material (short cut carbon fiber) 3.5 parts, thermally conductive filler (zinc oxide whiskers and calcium oxide particles compounded at a mass ratio of 1:3) 36 parts, toughening agent (POE and EVA compounded) 3 parts, coupling agent (liquid silane coupling Antioxidant) 0.1~2 parts, antioxidant (primary antioxidant 1098, auxiliary antioxidant 168) 1 part, processing aid (flame retardant) 5 parts.

[0070] 2. Preparation steps:

[0071] (1) After atomizing the coupling liquid silane coupling agent, pass the thermally conductive filler and carbon fiber composite material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com