Drilling and milling carbon fiber composite material follow-up dust collection device

A dust removal device and composite material technology, applied in the direction of dust removal, maintenance and safety accessories, use of liquid separation agent, etc., can solve the problem that dust cannot be fully collected in real time, and achieve the effect of non-destructive fast connection and prevention of floating everywhere

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

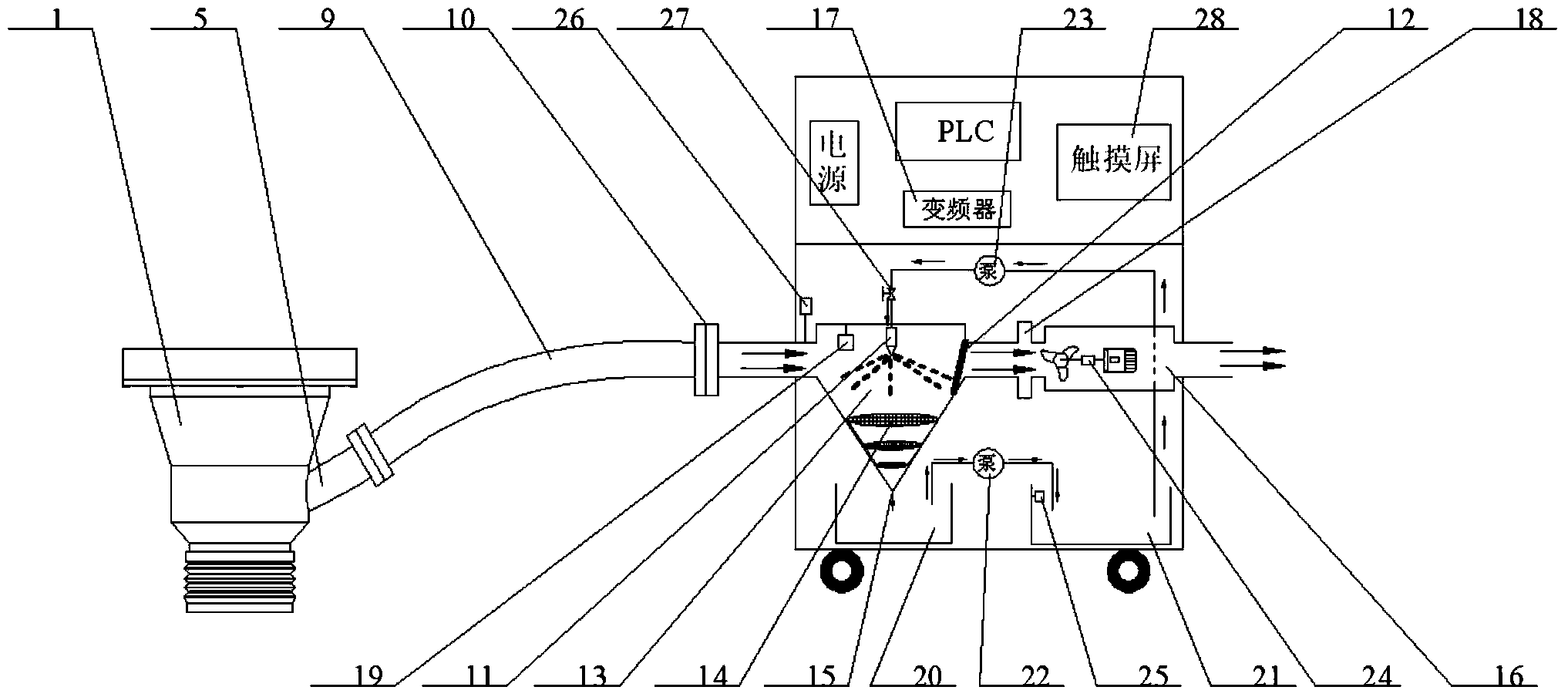

[0012] The specific implementation of the present invention is described in detail below in conjunction with accompanying drawing and technical scheme, present embodiment a kind of drilling and milling carbon fiber composite material follow-up dedusting device, the frequency converter in this device, PLC, high-pressure centrifugal fan, muffler, dust concentration transmitter , wind pressure sensor, displacement sensor, wet dust collector and water circulation filter device are all installed in the electric control cabinet to realize the online detection, control, adjustment and diagnosis functions of the dust removal system.

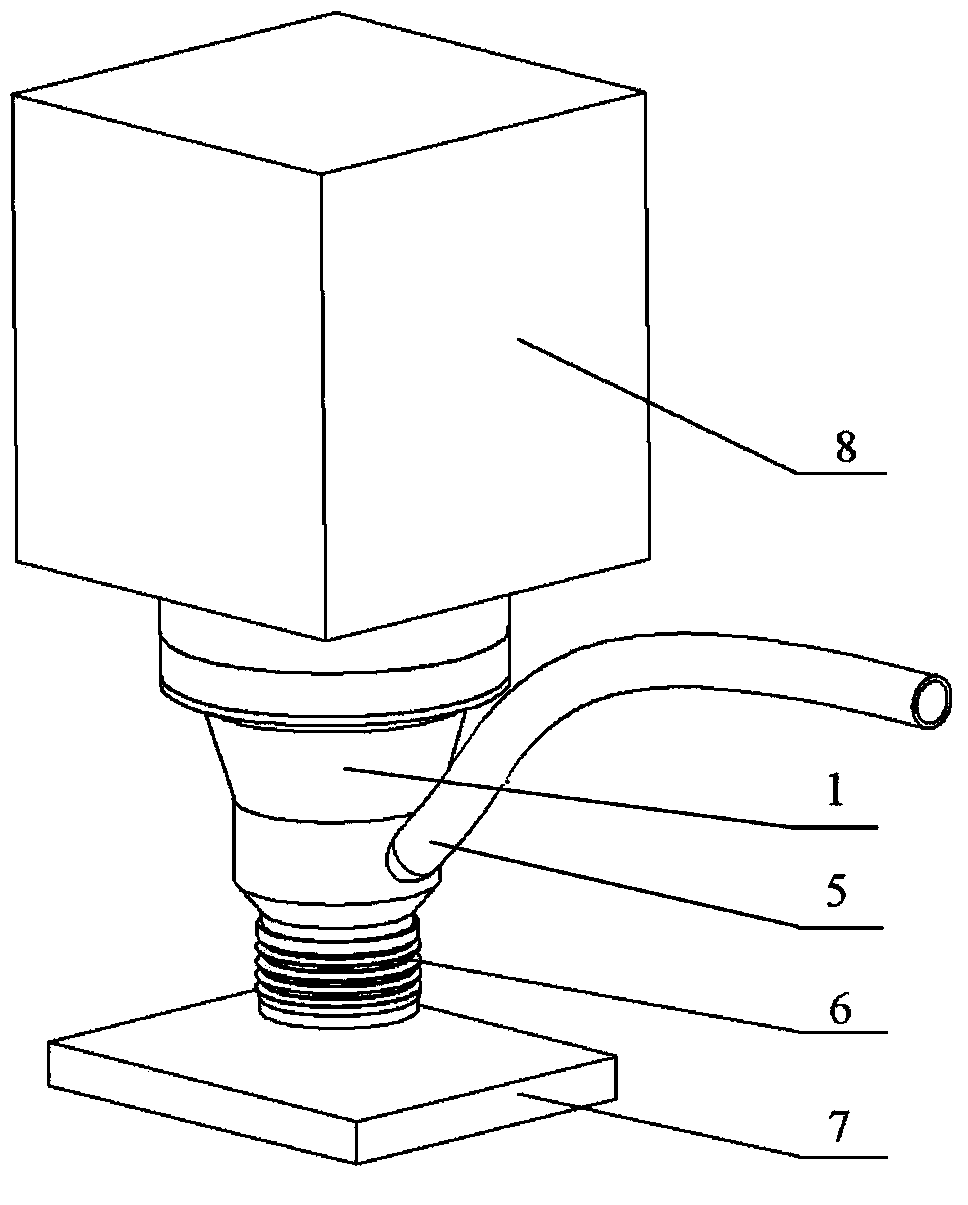

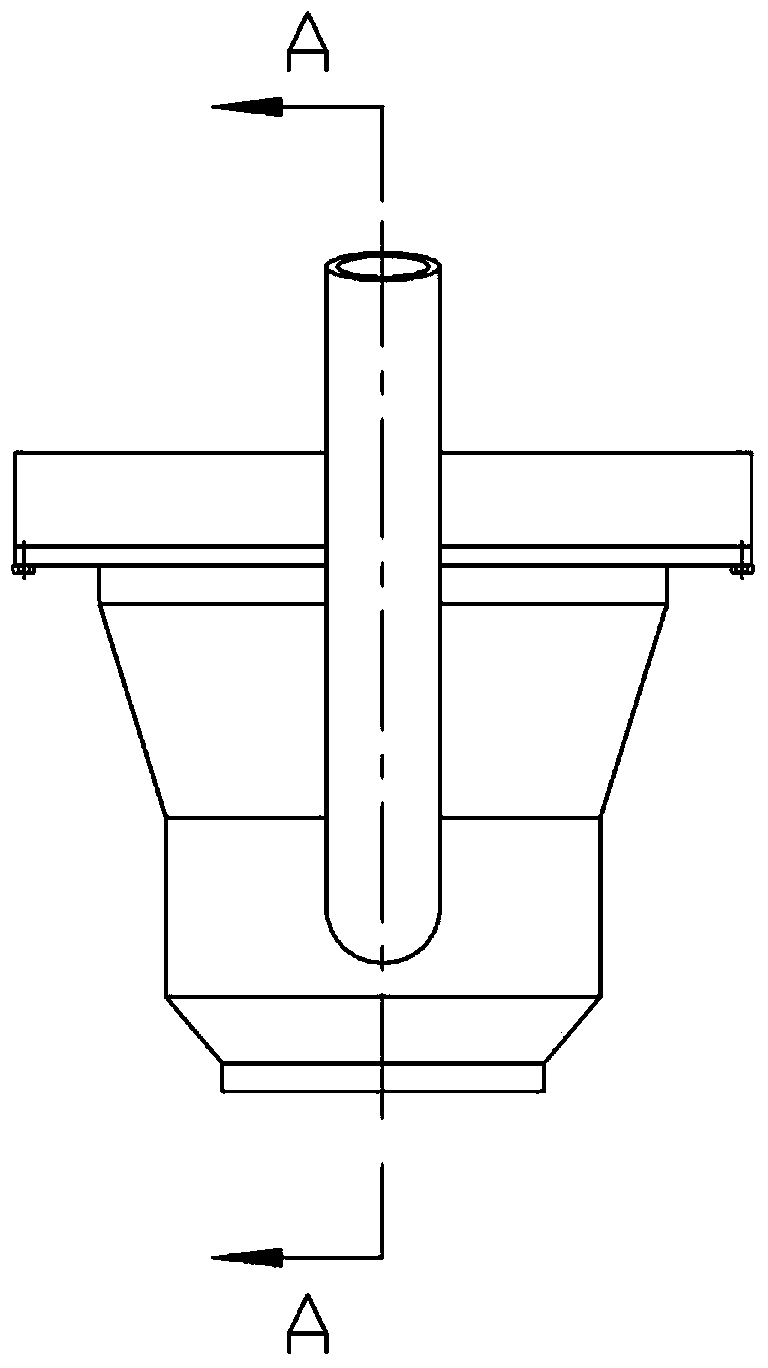

[0013] The working principle of the present invention is: the follow-up dust removal device has a chip collection assembly, a wet dust collector, a power part and a water filtration and circulation device, see the attached figure 1 . Fast and non-destructive connection is realized through the electromagnet chuck 3 in the chip collection assembly and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com