Metal-based carbon fiber composite material and producing method thereof

A technology of composite materials and manufacturing methods, applied in the direction of metal layered products, chemical instruments and methods, thin material processing, etc., can solve problems such as high temperature, and achieve the effect of high value and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

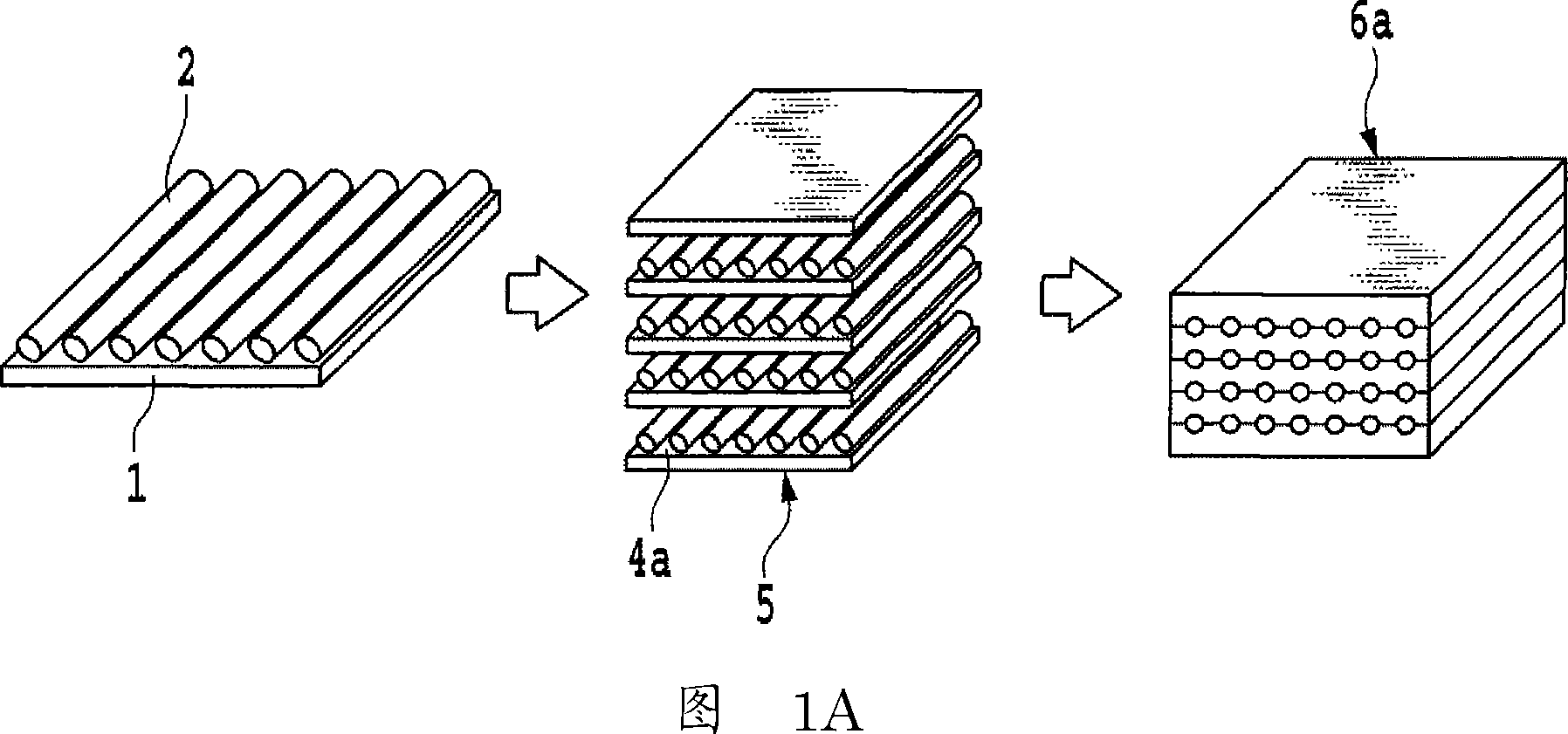

Embodiment 1

[0061] This embodiment provides a metal-based carbon fiber composite material, which uses carbon fibers that can be treated as continuous fibers, and the carbon fibers are aligned in one direction. As the carbon fiber, a pitch-based carbon fiber having a diameter of 10 μm continuous in the longitudinal direction and having a thermal conductivity of 1000 W / mK was used, and an aluminum foil having a thickness of 10 μm was used as the metal support. To fix the carbon fiber on the aluminum foil, the carbon fiber wound on the bobbin was pulled out using the apparatus shown in FIG. 2 , and low molecular weight polyethylene glycol was applied as a binder while applying tension. The following steps are continuously carried out: attaching carbon fibers aligned by tension to the unrolled aluminum foil, and winding up the foil after the adhesive is cured. Unwind the carbon fiber-attached aluminum foil (preform) from the roll, cut out a size of 200×300mm, stack 500 sheets, and laminate th...

Embodiment 2

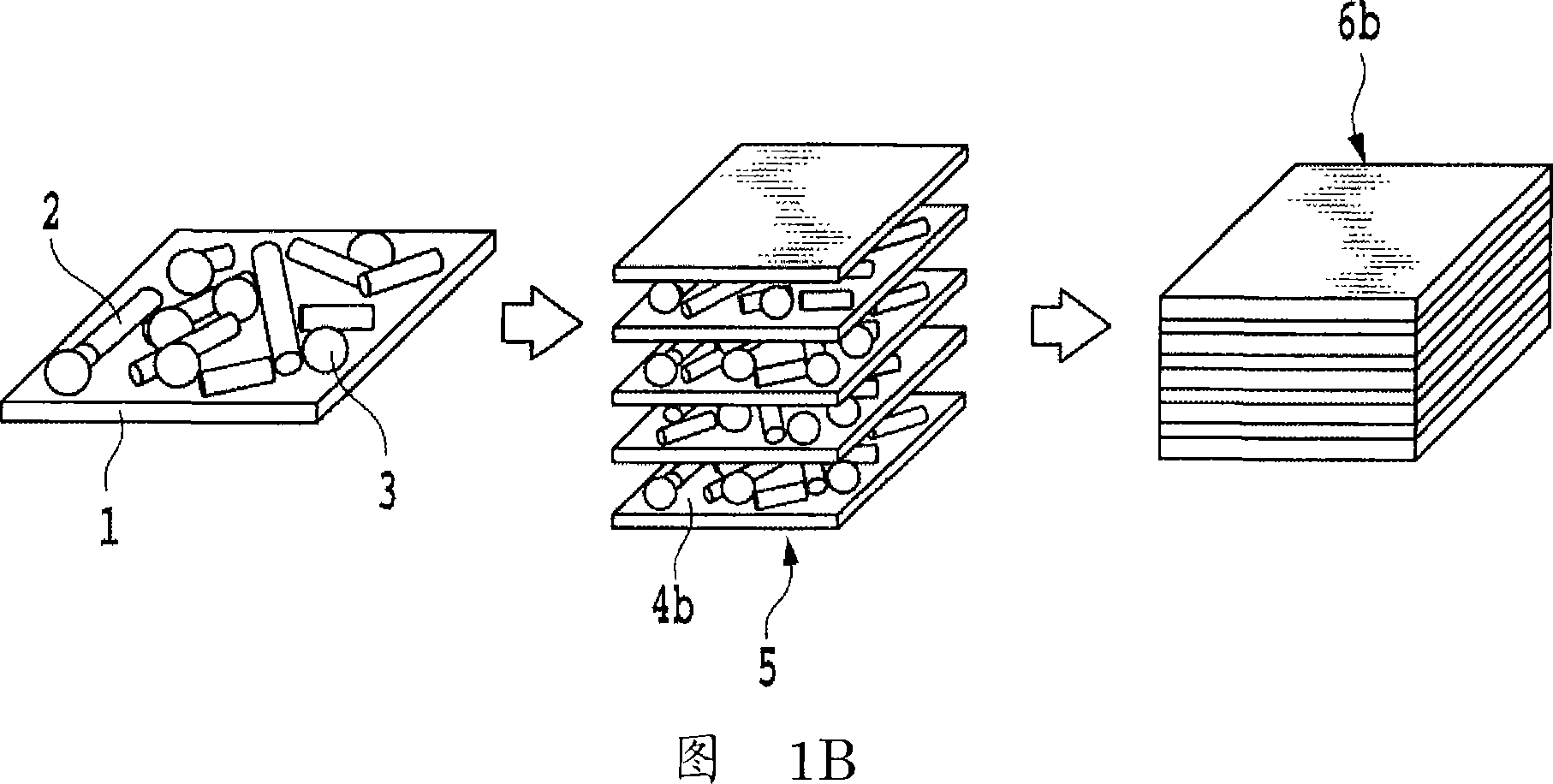

[0064] This embodiment provides a metal matrix carbon fiber composite material, which uses carbon fibers that can be treated as short fibers, and the carbon fibers are aligned in one direction. In a ball mill, the gas-phase grown carbon fiber with a diameter of 200nm, a length of 5-20μm, and a thermal conductivity of 2000W / mK is mixed with 30% of copper powder with a particle size of about 100nm. To the obtained mixture, acetone and Pluronic (registered trademark) F68 dispersion binder were added and mixed to obtain an ink-like coating mixture. By the spray printing method shown in Figure 3, the obtained coating mixture was printed on the entire surface of the copper foil with a thickness of 6 μm, and the film thickness became 6 μm to form a preform, and dispersed in Pluronic (registered trademark) F68 After the binder is cured, it is wound up on a roll. This preform was unwound from a roll, cut out to a size of 200×300 mm, and 500 sheets of the cut out preforms were stacked,...

Embodiment 3

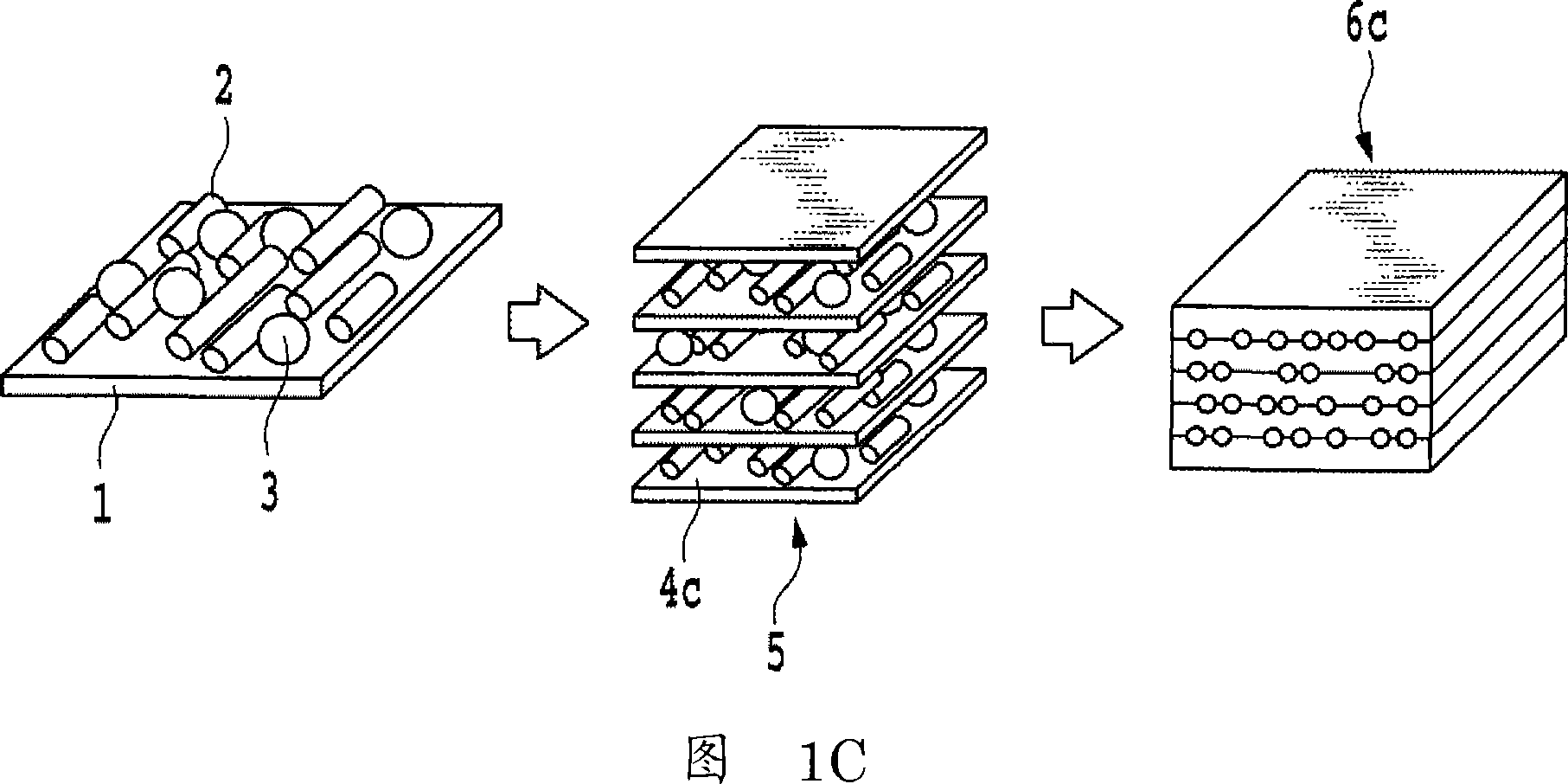

[0067] This embodiment provides a metal-matrix carbon fiber composite material that uses carbon fibers that can be processed as continuous fibers, which are aligned in one direction, and which are formed by pulse energization sintering as a small-scale-oriented method. Use pitch-based carbon fibers with a diameter of 10 μm, continuous in the length direction, and a thermal conductivity of 1,000 W / mK as carbon fibers, aluminum powder with an average particle size of 30 μm as a bonding auxiliary material, and an aluminum sheet with a thickness of 100 μm as a metal support . Initially, aluminum powder was suspended in ethanol solvent. About 6,000 carbon fibers were held in bundles, immersed in the suspension, and then only ethanol was evaporated to obtain carbon fibers in a state where aluminum powder was also adhered to the surface of the carbon fibers by electrostatic force after the solvent was dried. As the pulse energization sintering furnace shown in FIG. 8B , a furnace pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com