Coating method of high-density Ni layer of carbon nano tube

A carbon nanotube, high-density technology, applied in the nano field, can solve the problems of difficult control of process parameters, high energy consumption, complex equipment, etc., and achieve the effects of excellent throwing and deep plating ability, uniform coating and simple process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

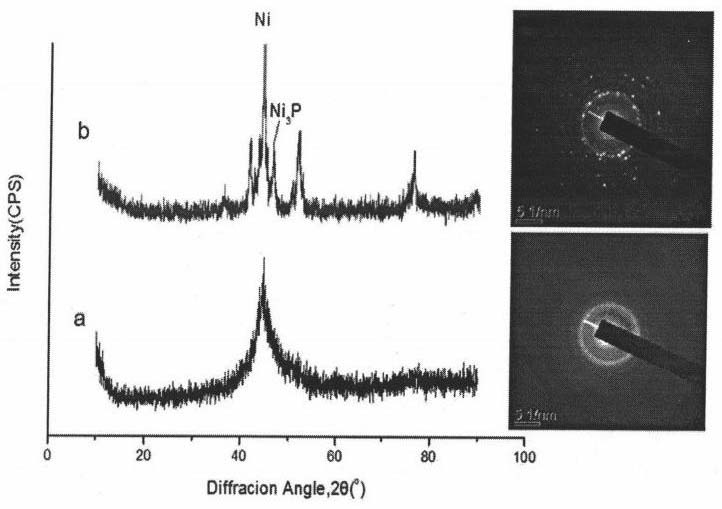

Image

Examples

Embodiment Construction

[0014] The present invention is a kind of coating method of carbon nanotube high-density Ni layer, and its steps are:

[0015] (1) Purify the carbon nanotubes first: put the carbon nanotubes into the 3 and concentrated H 2 SO 4 Soak in the mixed acid prepared at a volume ratio of 1:3 for 24 hours, then rinse repeatedly with deionized water, let it stand for 4 hours, collect the supernatant, and rinse several times until PH=7; all the collected supernatant The liquid was allowed to stand for 24 hours to make it precipitate, and then the precipitate was filtered and dried;

[0016] (2) Sensitize the carbon nanotubes of the purified supernatant: put the purified carbon nanotubes into the sensitization solution for 30 minutes, so that the SnCl 2 Deposit on the surface of carbon nanotubes, then wash the solution repeatedly until pH = 7, then dry it; the composition of the sensitization solution is SnCl 2 2H 2 O: 20g / L, HCl: 40g / L;

[0017] (3) Activating the sensitized carbon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com