Surface modifying method for lithium nickel manganese oxide positive electrode material

A technology of lithium nickel manganese oxide and surface modification, which is applied in the direction of battery electrodes, electrical components, circuits, etc., can solve the problems of uniform and complete coating of difficult materials, large energy consumption, complex process, etc., and achieve improved activation effect, electrical Improved chemical properties and uniform nickel coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

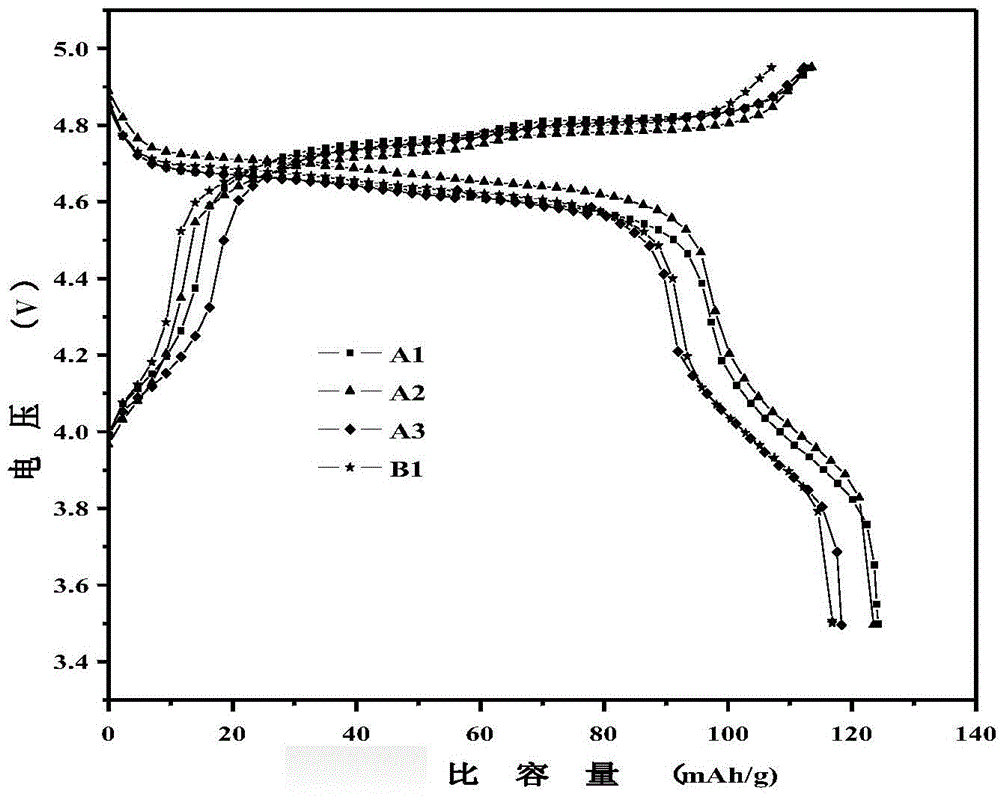

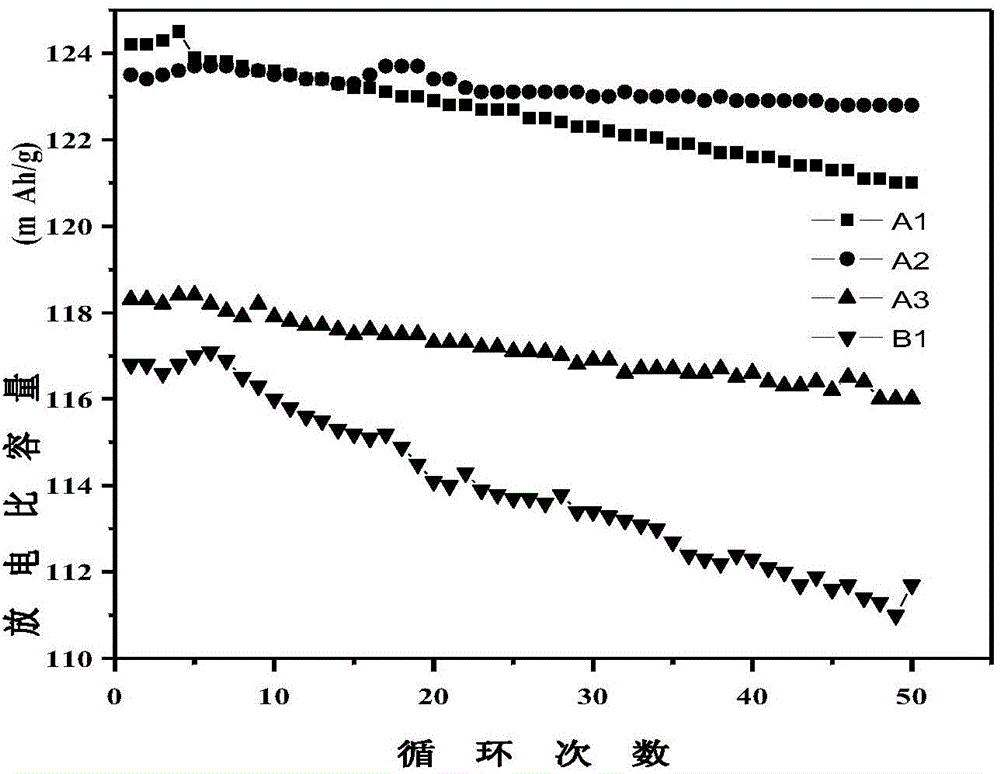

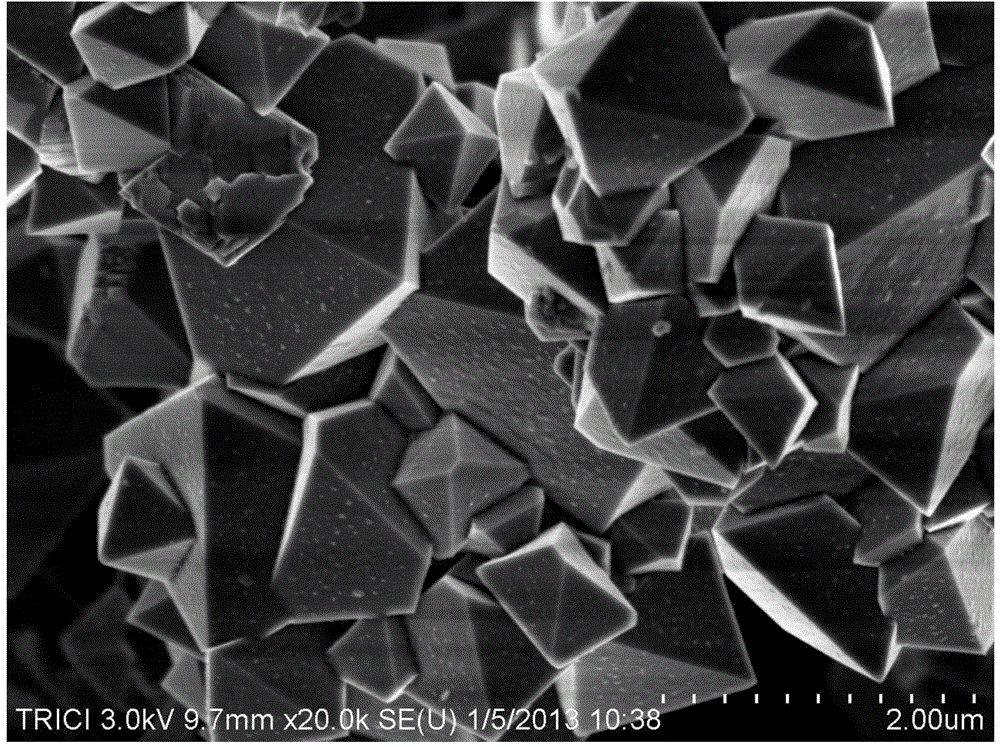

[0025] Example 1: First, prepare lithium nickel manganese oxide powder, and prepare an activation solution according to the ratio of 80 g of nickel acetate, 96 g of sodium citrate, and 1 L of methanol, and adjust the pH value of the activation solution to 8 with ammonia water; Immerse in the 200mL activation solution prepared above, ultrasonically disperse and activate at room temperature for 30min, filter with suction, and wash with water until neutral; heat the activated lithium nickel manganese oxide at 300°C for 20min in a constant temperature electric heating box to obtain a substrate with elemental nickel on the surface 80.2g (activation treatment is a catalyst for forming a layer of electroless nickel plating on the surface of the nickel-plated substance, so that the nickel plating can proceed smoothly, and the activation solution used can be reused);

[0026] nickel sulfate (NiSO 4 )7g (0.045mol), sodium hypophosphite (NaH 2 PO 2 )7g (0.080mol), ammonium chloride (NH...

Embodiment 2

[0028] Example 2: First, prepare lithium nickel manganese oxide powder, and prepare an activation solution according to the ratio of 80 g of nickel acetate, 96 g of sodium citrate, and 1 L of methanol, and adjust the pH value of the activation solution to 8 with ammonia water; Immerse in the 200mL activation solution prepared above, ultrasonically disperse and activate at room temperature for 40min, filter with suction, and wash with water until neutral; heat the activated lithium nickel manganese oxide at 310°C for 20min in a constant temperature electric heating box to obtain a substrate with elemental nickel on the surface ;

[0029] Dissolve 7g (0.045mol) of nickel sulfate, 7g (0.080mol) of sodium hypophosphite, 3g (0.056mol) of ammonium chloride, and 5g (0.045mol) of sodium lactate in 200mL of deionized water to form a plating solution. The concentration of pH value is 10mL The / L triethanolamine was adjusted to 9, and the surface-activated lithium nickel manganese oxide ...

Embodiment 3

[0030] Example 3: First, prepare lithium nickel manganese oxide powder, and prepare an activation solution according to the ratio of 80 g of nickel acetate, 96 g of sodium citrate, and 1 L of methanol, and adjust the pH value of the activation solution to 8 with ammonia water; mix 80 g of lithium nickel manganese oxide Immerse in the 200mL activation solution prepared above, ultrasonically disperse and activate at room temperature for 40min, filter with suction, and wash with water until neutral; heat the activated lithium nickel manganese oxide at 310°C for 20min in a constant temperature electric heating box to obtain a substrate with elemental nickel on the surface ;

[0031] Dissolve 10g (0.064mol) of nickel sulfate, 10g (0.114mol) of sodium hypophosphite, 3g (0.056mol) of ammonium chloride, and 6g (0.054mol) of sodium lactate in 200mL of deionized water to form a plating solution. The concentration of pH value is 10mL The / L triethanolamine was adjusted to 9, and the surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com