Electronic component package and method for producing same

一种电子部件、制造方法的技术,应用在半导体/固态器件制造、电气元件、电固体器件等方向,能够解决镀敷层剥落、未涉及系统级封装等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

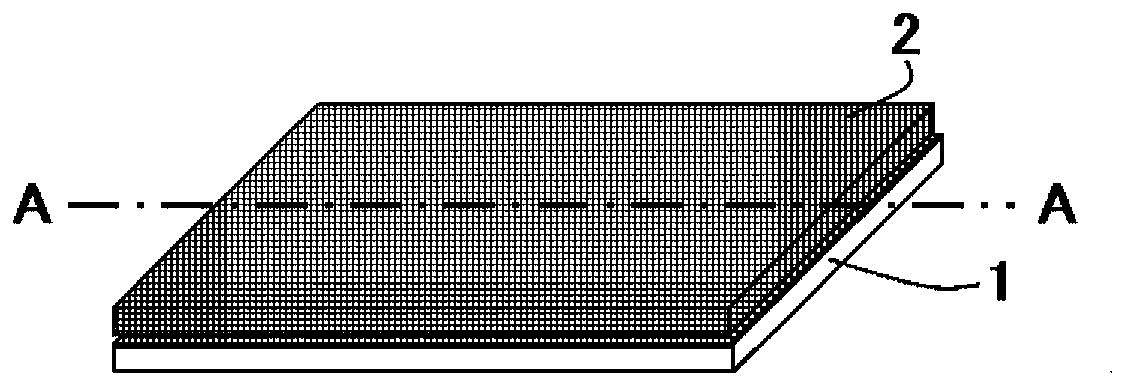

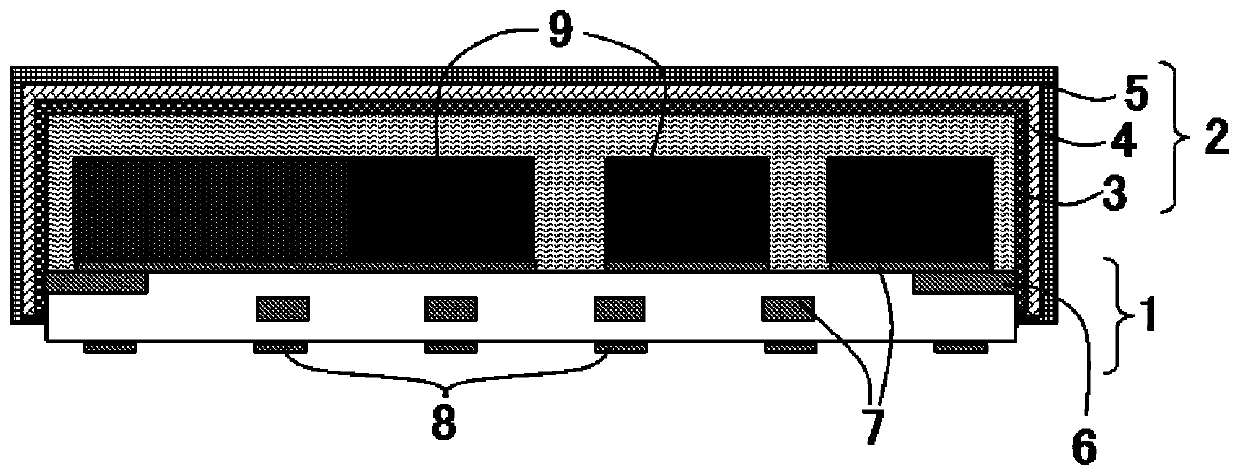

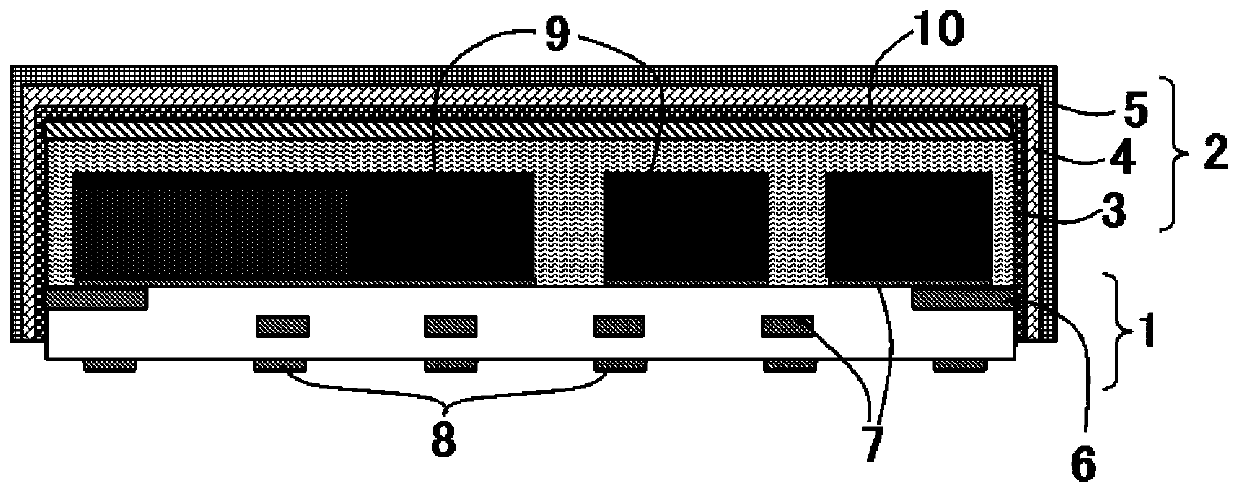

Image

Examples

Embodiment

[0095] Hereinafter, the present invention will be described in detail through examples.

[0096] (Preparation example 1: Preparation of metal particle dispersion liquid)

[0097] In a mixed solvent of 30 parts by mass of ethylene glycol and 70 parts by mass of ion-exchanged water, a compound obtained by adding polyethylene oxide to polyethyleneimine was used as a dispersant to disperse silver particles with an average particle diameter of 30 nm, and then add Water, ethanol, and surfactant were ion-exchanged, and the viscosity was adjusted to 10 mPa·s to prepare a metal particle dispersion. It should be noted that the metal particle dispersion liquid contains metal particles and a polymer dispersant having a nitrogen atom-containing basic group as a reactive functional group.

manufacture example 1

[0098] (Manufacturing example 1: Manufacture of polymer layer resin)

[0099] In a reaction vessel equipped with a stirrer, a reflux cooling pipe, a nitrogen gas introduction pipe, and a thermometer, in a mixed solvent of 111 parts by mass of methyl ethyl ketone, polycarbonate polyol (1,4-cyclohexanedimethanol and 100 parts by mass of polycarbonate diol having an acid group equivalent of 1,000 g / equivalent), 9.7 parts by mass of 2,2-dimethylolpropionic acid, and 5.5 parts by mass of 1,4-cyclohexanedimethanol obtained by the carbonate reaction 51.4 parts by mass of dicyclohexylmethane diisocyanate were reacted to obtain an organic solvent solution of a urethane prepolymer having an isocyanate group at a molecular terminal.

[0100]Next, by adding 7.3 parts by mass of triethylamine to the organic solvent solution of the above-mentioned polyurethane resin to neutralize part or all of the carboxyl groups contained in the above-mentioned polyurethane resin, and further adding 355 p...

Embodiment 1

[0107] An electronic component mounted on a circuit board having a ground pattern is sealed with a resin composition for encapsulating a semiconductor containing an epoxy resin, a phenolic resin curing agent, and a filler. On the surface of the sealing body, the metal particle dispersion liquid prepared in Preparation Example 1 was coated with a spray device (a spray device equipped with a spray tip QTKA (flow size: 0.1 L / min) of a nozzle manufactured by Spraying Systems Japan Co., Ltd.). The film thickness after drying as the metal particle layer was 150 nm. Then, it was dried at 180° C. for 10 minutes to form a metal particle layer. The surface resistance value of this metal particle layer was 4Ω / □.

[0108] Next, on the metal particle layer formed by the above method, phosphorus-containing copper is set as an anode, and an electroplating solution containing copper sulfate is used at a current density of 2.5A / dm 2 Copper electroplating was performed for 10 minutes to lamin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| viscosity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com