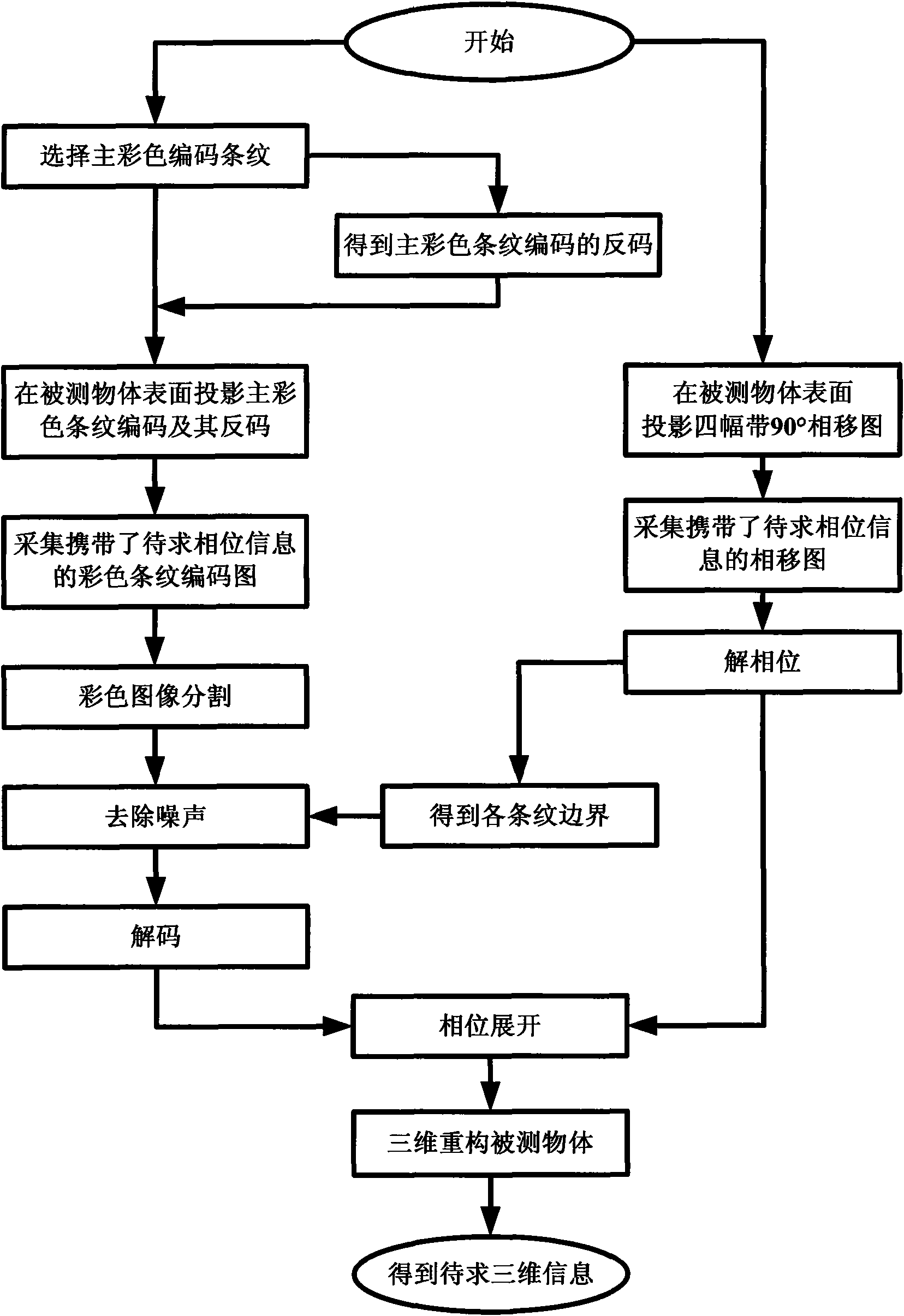

Three-dimensional measuring method based on positive and inverse code color encoding stripes

A color-coded, three-dimensional measurement technology, used in measurement devices, image data processing, instruments, etc., to solve problems such as segmentation deviation, misjudgment, and inaccurate thresholds.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The specific implementation manners of the present invention will be further described below in conjunction with the drawings. According to the above-mentioned method, the operation of the fringe color coding method of the grating fringe image based on the gray coding principle is realized by using the VC++6.0 platform in the Windows operating system with C++ programming.

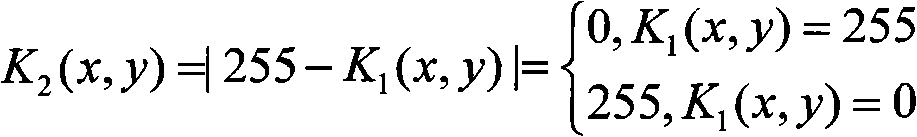

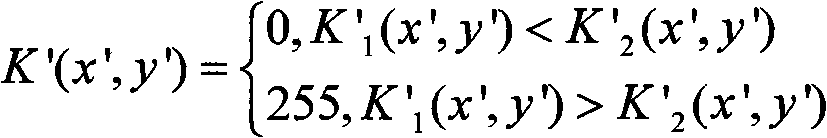

[0040] The requirements for real-time and effectiveness of 3D measurement are a pair of contradictions. Color images contain more information than grayscale images. Using color gratings can achieve faster measurement speeds than using black and white gratings. In order to improve the real-time performance of 3D measurement, use One color-coded stripe replaces seven black-and-white stripes that are gradually dichotomized. However, color-coded stripes are more likely to be affected by the surface color of the measured object and change color than black and white stripes. The CCD collects the background,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com