Tyre touchdown shape measuring device using laser disperse spot shearing interference method

A technology of laser speckle and measuring device, applied in measuring device, optical device, tire installation, etc., can solve problems such as large embossing error and inability to quantify pressure distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

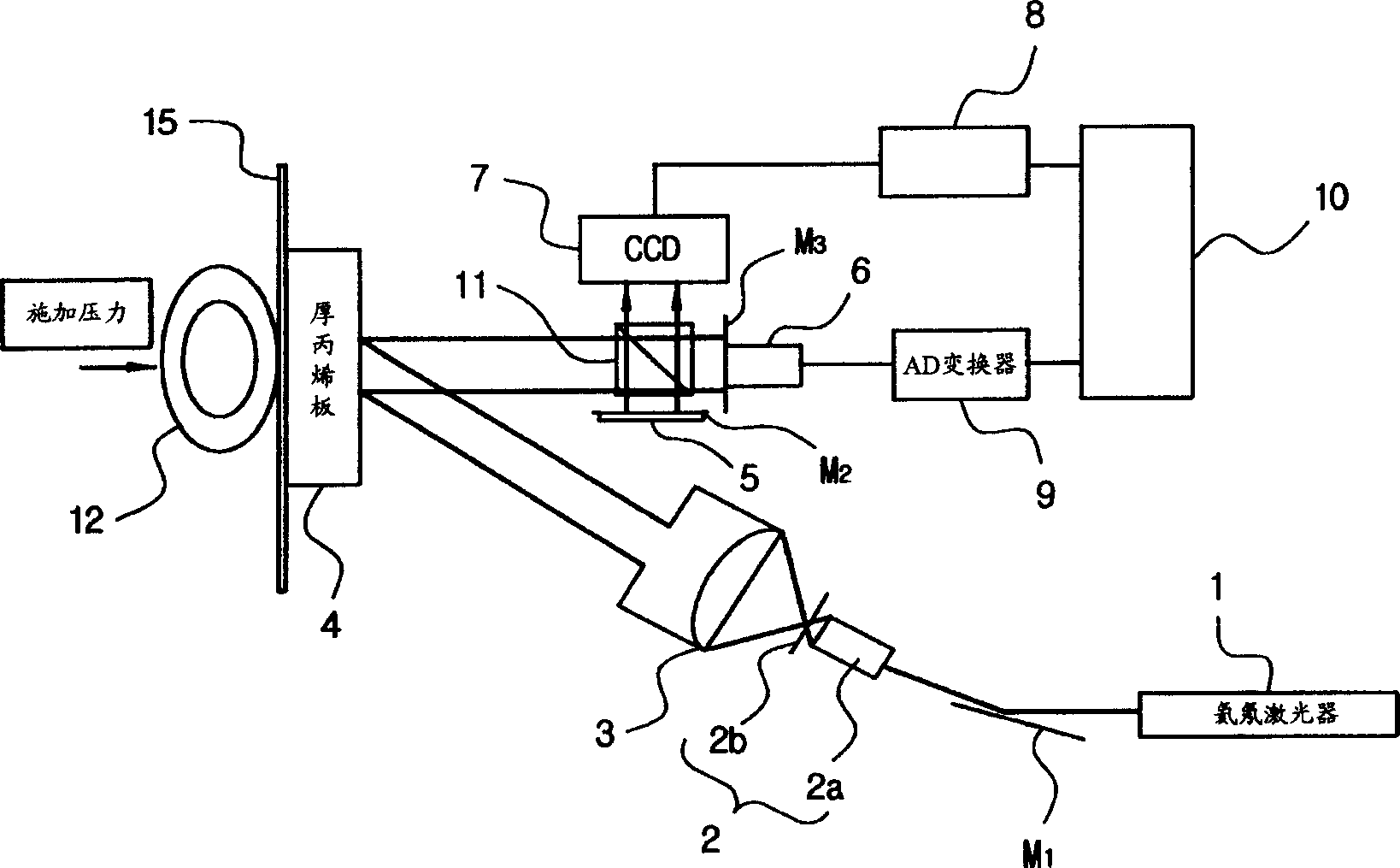

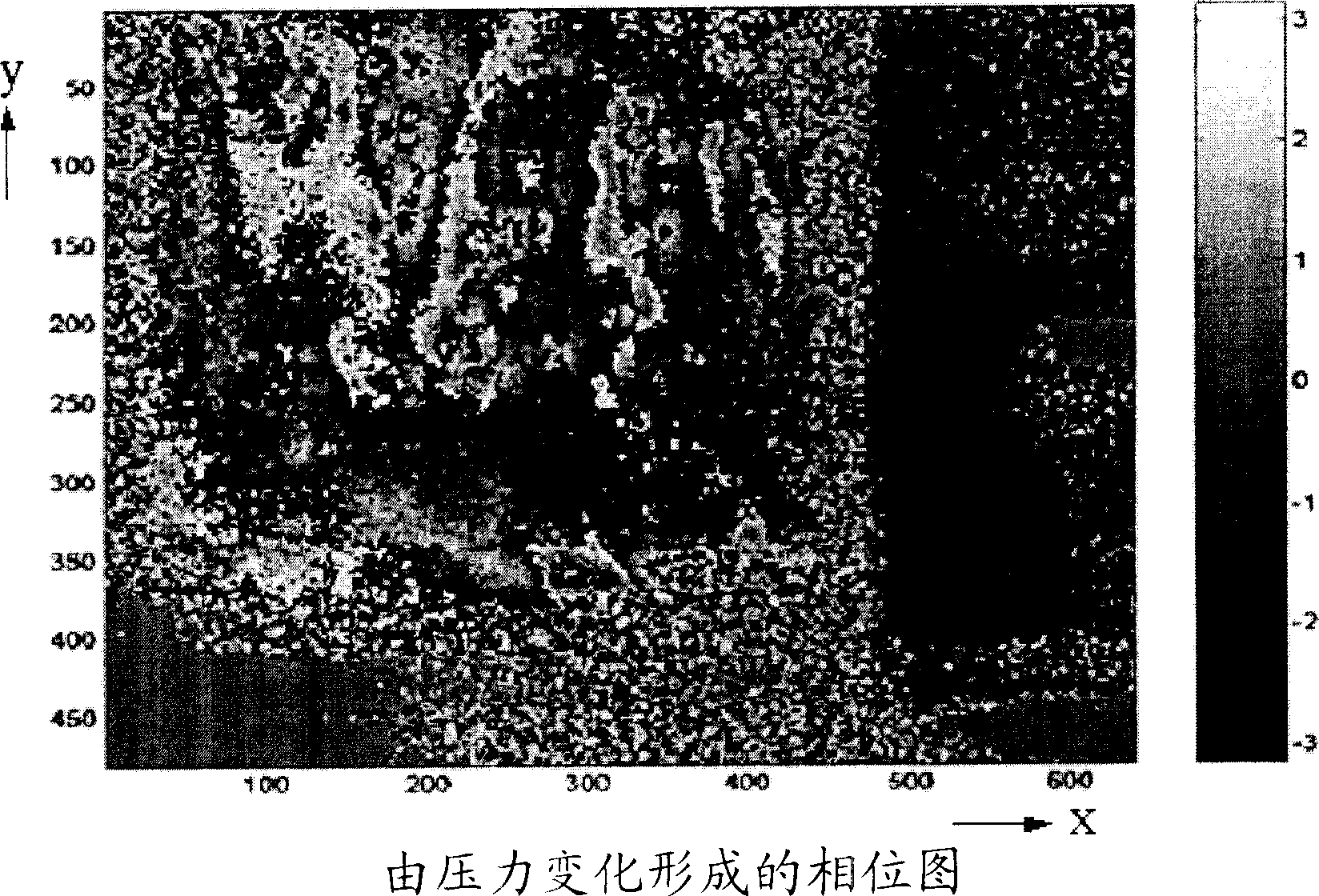

Method used

Image

Examples

Embodiment Construction

[0015] First, technologies in the technical field related to the present invention will be described.

[0016] In general, when a rough surface is irradiated with light with good coherence such as laser light, speckle, which is an unintentional change in brightness distribution, can be observed. This phenomenon is called the speckle effect, and it can be seen sufficiently even with the naked eye. In addition, the speckle effect can be observed regardless of the position of the recording surface or the presence or absence of a lens.

[0017] As mentioned above, speckle contains information such as roughness, deformation, and displacement of the object surface. A speckle pattern interferometer (SPI: Speckle Pattern Interferometer) is an optical interferometer that uses a speckle pattern with the above information as a material to observe the state of an object to be measured.

[0018] Electronic Speckle Pattern Interferometry (ESPI: Electronic Speckle Pattern Interferometry) i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com