Method for preparing high-strength alginic acid/gelatin cross-blend fiber and its use

A technology of gelatin blended fiber and alginic acid, which is applied in the field of polymer chemical materials, and can solve the problems of unsatisfactory elasticity and strength of alginic acid fiber

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

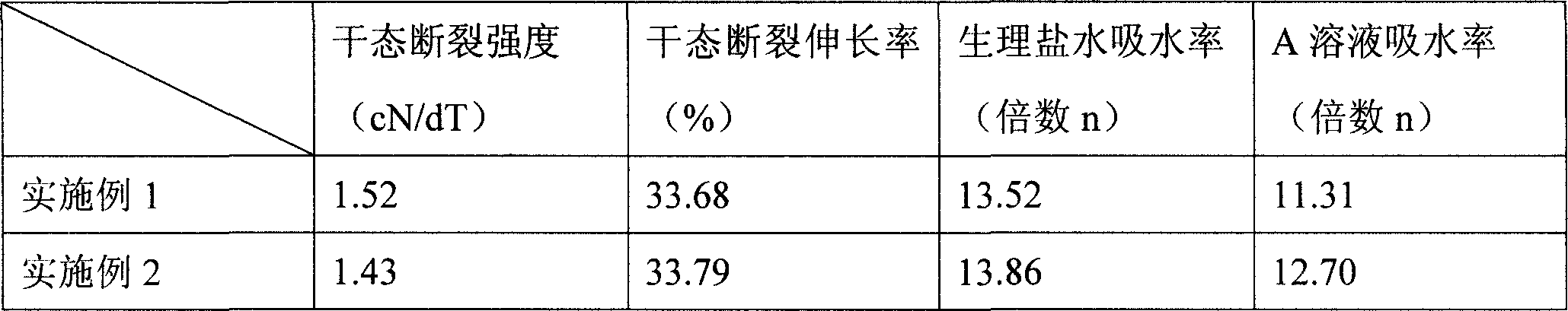

Embodiment 1

[0022] Example 1: Dissolve 30g of sodium alginate powder in 970g of distilled water at room temperature, stir and dissolve to obtain sodium alginate solution; dissolve 30g of gelatin in 470g of distilled water at 50°C, stir and dissolve to obtain gelatin aqueous solution; choose NaOH, triethanolamine or Na 2 HPO 4 Any one of the aqueous solutions in the gelatin aqueous solution is used as an alkali agent to adjust the pH value of the aqueous gelatin solution, and the pH value of the aqueous gelatin solution is adjusted to 8.0, 8.2, 8.25, 8.3, 8.5 or 9.0. The above two solutions are blended, and the aqueous gelatin solution and sodium alginate solution The mixing ratio (volume ratio) can be selected as 10:100, 20:100, 30:100 or 50:100, the blended solution is vigorously stirred to a homogeneous system, and degassing under reduced pressure at 33°C; at 33±1°C Next, the primary fiber is first formed by wet spinning in a metal coagulation bath, the metal coagulation bath can be 2%,...

Embodiment 2

[0023] Example 2: Dissolve 60g of sodium alginate powder in 940g of distilled water at room temperature, stir and dissolve to obtain sodium alginate solution; dissolve 60g of gelatin in 440g of distilled water at 70°C, stir and dissolve to obtain gelatin aqueous solution; choose NaOH, triethanolamine or Na 2 HPO 4 Any one of the aqueous solutions in the gelatin aqueous solution is used as an alkali agent to adjust the pH value of the aqueous gelatin solution, and the pH value of the aqueous gelatin solution is adjusted to 8.0, 8.2, 8.25, 8.3, 8.5 or 9.0. The above two solutions are blended, and the aqueous gelatin solution and sodium alginate solution The mixing ratio (volume ratio) can be selected as 10:100, 20:100, 30:100 or 50:100, the blended solution is vigorously stirred until it becomes a homogeneous system, and degassing under reduced pressure at 33°C; at 33±1 At ℃, first adopt the wet spinning method to form the primary fiber in the metal coagulation bath, the metal c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com