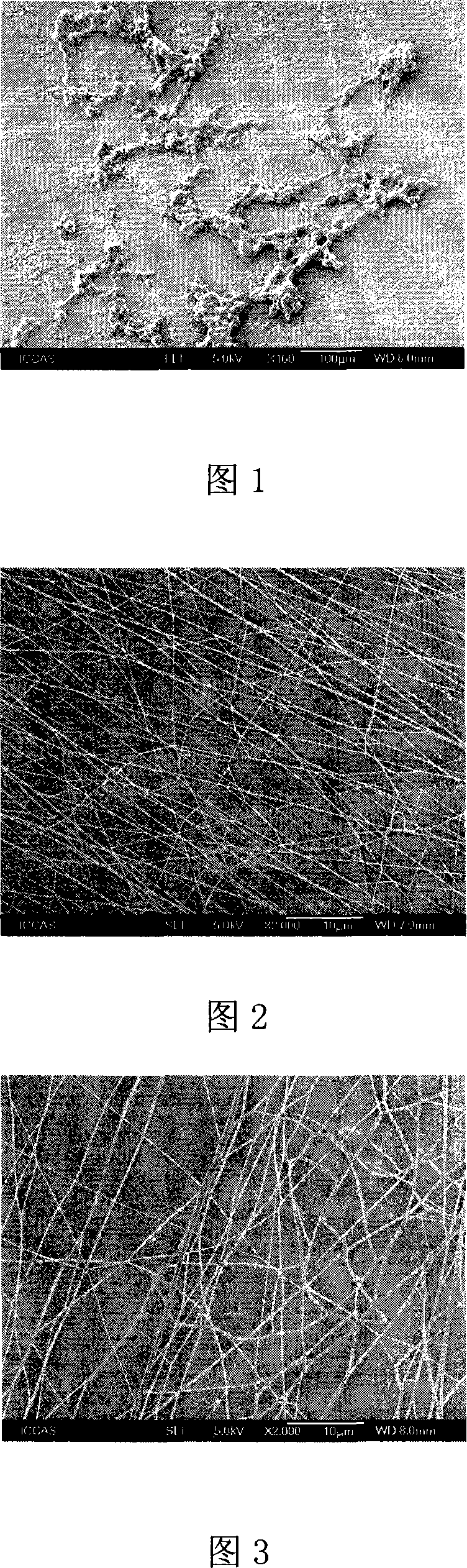

Method for preparing pure sodium alginate nano fiber membrane material

A technology of nanofiber membrane and sodium alginate, which is applied in fiber treatment, spinning solution preparation, alginate artificial filament, etc., can solve the problems such as no pure sodium alginate electrospinning reported in the literature, and achieve cost cheap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

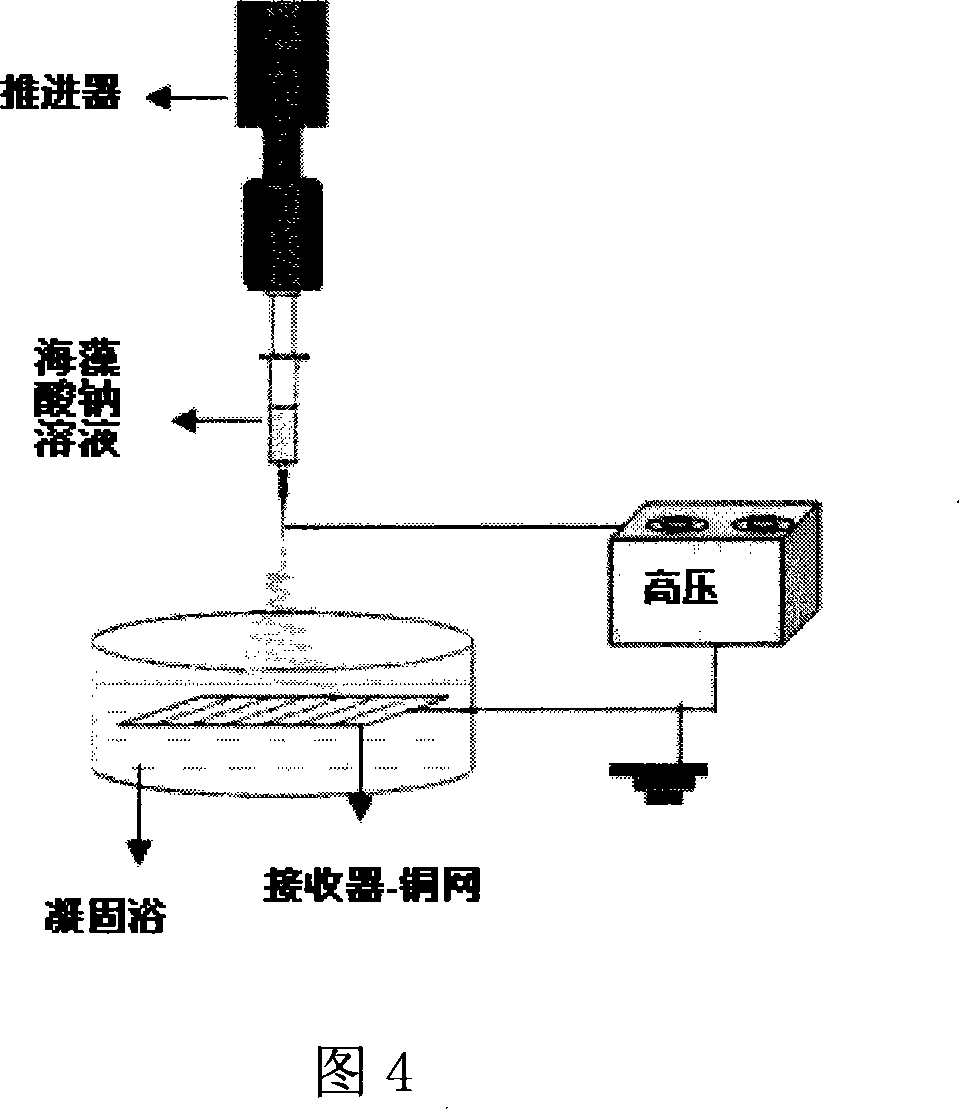

[0022] Step 1: Use sodium alginate with a viscosity of 3500 centipoise as the raw material, and the modifier is glycerin, and uniformly disperse the sodium alginate in glycerin at room temperature, wherein the weight-to-volume ratio of sodium alginate to glycerin is 4g / ml %.

[0023] Step 2: Add solvent water to the above suspension, wherein the volume ratio of water to glycerin is 1, and continue to stir until it dissolves into a uniform and transparent solution.

[0024] Step 3: Inject the above-mentioned solution that has been left standing to remove air bubbles into the electrospinning container. ) and the distance between the spinneret is 12cm. Turn on the feeding device pump equipped with the sodium alginate electrospinning stock solution, the jet stream is sprayed on the collector, the electrospinning process is stable, and the collector completely immersed in the coagulation bath (the coagulation bath is a mass percent concentration of 10% CaCl 2 The mixed solution ...

Embodiment 2

[0027]Step 1: Use sodium alginate with a viscosity of 3500 centipoise as the raw material, and the modifier is glycerin, and uniformly disperse the sodium alginate in the modifier at room temperature, wherein the weight-to-volume ratio of sodium alginate to glycerol is 3g / ml%.

[0028] Step 2: Add solvent water to the above suspension, wherein the volume ratio of water to glycerin is 0.5, and continue to stir until it dissolves into a uniform and transparent solution.

[0029] The third step: inject the above-mentioned solution that has been left to remove air bubbles into the electrospinning container, the spinning temperature is room temperature, the output voltage of the high-voltage power supply is 28KV, and the feeding rate is 108μl / min. The distance between the wire heads is 12cm. Open the feeding device pump equipped with sodium alginate electrospinning stock solution, the jet stream is sprayed on the collector, the electrospinning process is stable, and the collector...

Embodiment 3

[0032] The first step: the sodium alginate with a viscosity of 5000 centipoise is a raw material, and the modifier is a mixture of glycerol and ethylene glycol (the volume ratio of glycerol and ethylene glycol is 3: 1), and the sodium alginate is mixed at room temperature Uniformly dispersed in the modifier, wherein the weight-to-volume ratio of sodium alginate to the mixed modifier is 3.0 g / ml%.

[0033] The second step: add the mixed solution of solvent water and ethanol (the volume ratio of water and ethanol is 2: 1, wherein the volume ratio of solvent (i.e. the total volume of water and ethanol) to modifying agent is 4: 3 in the suspension) , continue to stir until it dissolves into a homogeneous and transparent solution.

[0034] The third step: inject the above-mentioned solution that has been left to remove air bubbles into the electrospinning container, the spinning temperature is room temperature, the output voltage of the high-voltage power supply is 28KV, and the fe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com