Electric spinning-in-situ photopolymerization apparatus and process for preparing nanometer fiber

A nanofiber and electrospinning technology, which is applied in the field of electrospinning, can solve the problems of poor mechanical strength of electrospun membranes, achieve the effect of improving mechanical strength and water resistance, and leaving no residue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

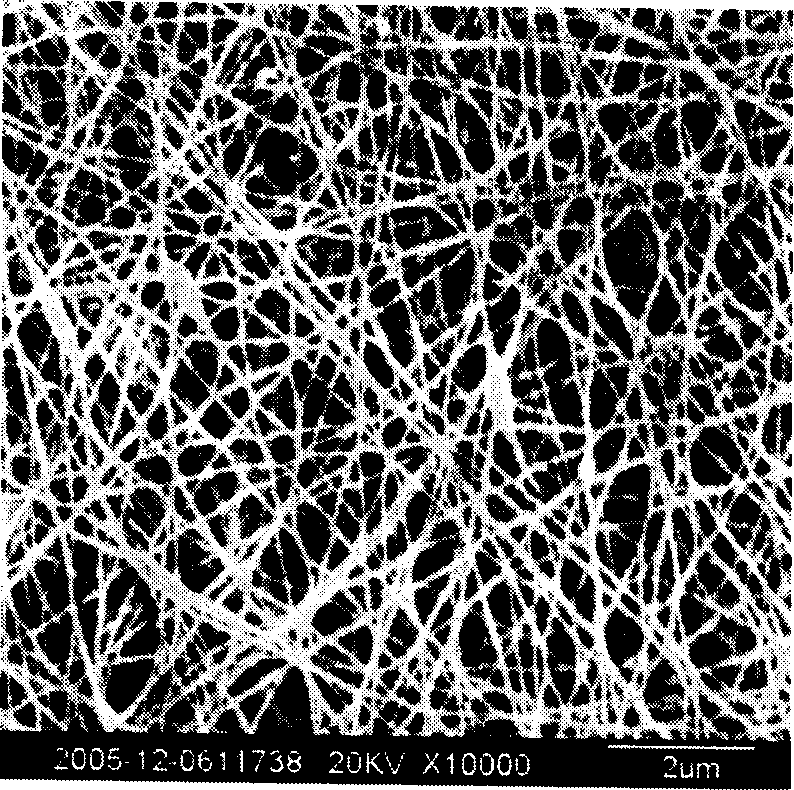

[0025] (1) Weigh 9.00 g polyvinyl alcohol (polymerization degree 3500, alcoholysis degree 88%), dissolve in 100 ml deionized water, and prepare 9% PVA aqueous solution. Weigh 7.00g chitosan (viscosity average molecular weight 120000, degree of deacetylation 82.5%) and dissolve in 20% (v / v) acrylic acid solution (acrylic acid 20.0ml, deionized water 80.0ml). Take 3.0ml of PVA aqueous solution and 1.6ml of chitosan acrylic acid solution, mix well, add ethylene glycol diacrylate 0.0764g, then add photoinitiator 1173 (2-hydroxy-2-methyl-1-phenylacetone -1) 0.0076g, mix well and defoam.

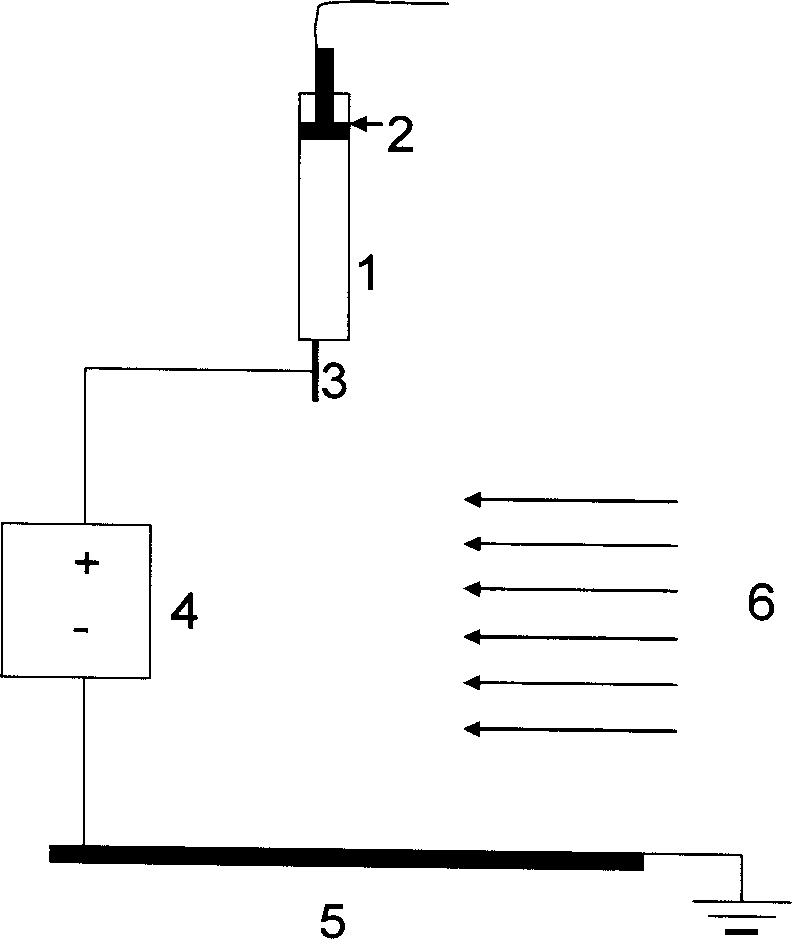

[0026] (2) Electrospinning the mixed liquid obtained in the step (1), supplemented by UV ultraviolet light at the same time, to obtain a nanofiber nonwoven fabric with excellent mechanical properties and water resistance. The mixed solution is added in the spinning vessel 1 of the spinning device, the flow velocity at the solution spinning outlet 3 is about 1.0ml / h, the applied voltage is 26KV, a...

Embodiment 2

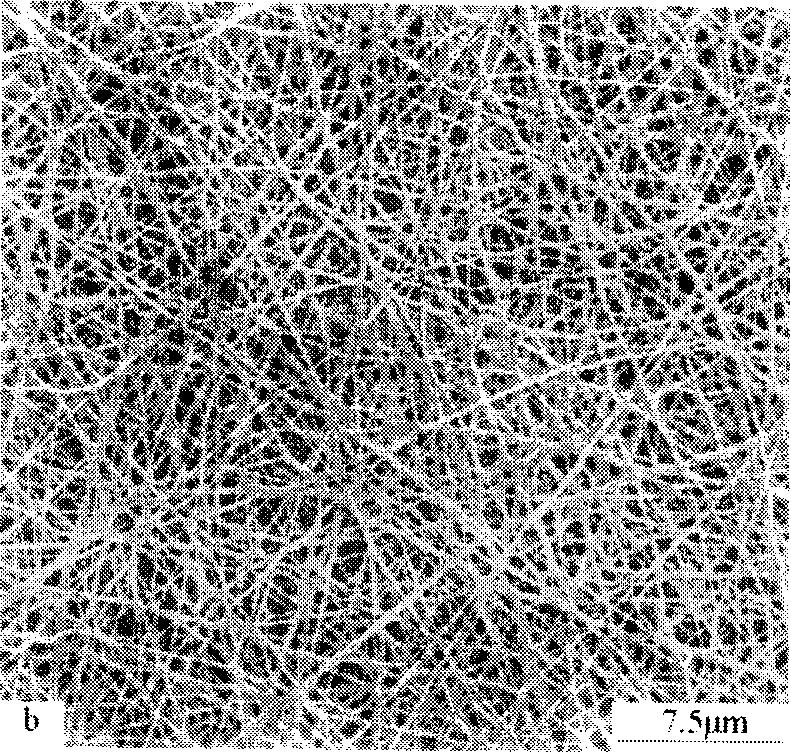

[0031] All other steps, conditions are with embodiment 1. The difference is that 0.0038 g of polyethylene glycol bis(meth)acrylate was added, and 0.00004 g of DMPA (α,α-dimethoxy-α-phenylacetophenone) was added.

Embodiment 3

[0033] All other steps, conditions are with embodiment 1. The difference is that 0.0764 g of pentaerythritol tetraacrylate was added, and 0.0008 g of photoinitiator 1173 (2-hydroxy-2-methyl-1-phenylacetone-1) was added.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com