Preparation method of oriented conductive hydrogel fiber material

A technology of conductive hydrogel and fiber materials, applied in the direction of conductive/antistatic filament manufacturing, fiber treatment, fiber chemical characteristics, etc., can solve the problems affecting the sensitivity and limitations of conductive materials, and achieve increased conductivity and tensile strength Elongation and the effect of expanding the application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

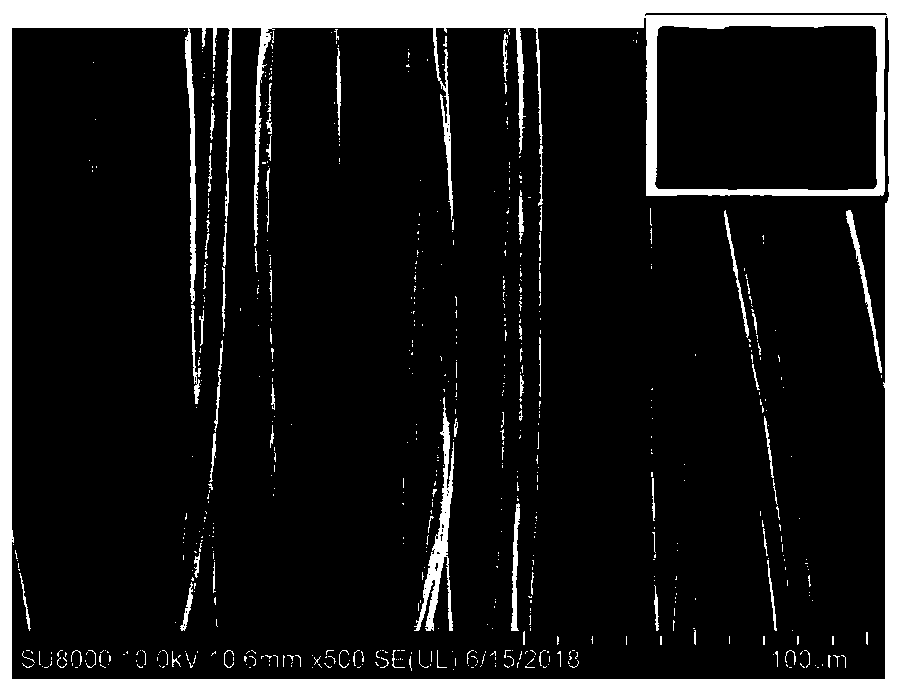

[0018] Example 1: Sodium alginate-carbon nanotube composite oriented conductive hydrogel fiber

[0019] Add different masses of carbon nanotubes and 5% carbon nanotubes of Pluronic F-127 into deionized water for magnetic stirring, then put them in an ice bath for ultrasonic dispersion, the dispersion power is 300W, and the dispersion time is 30-120min. A 0.2mg / ml-5mg / ml carbon nanotube dispersion is obtained. Mix 1% sodium alginate and 0.2% PEO with the above dispersion, and perform magnetic stirring for 1 h to obtain an electrospinning precursor. Inhale the precursor solution into a 1ml electrospinning syringe and fix it on the propulsion pump, set the propulsion speed to 1-2ml / h, connect the positive pole of the high voltage power supply to the spinning nozzle, and the negative pole to the receiving tray, adjust the electrospinning The distance between the needle and the receiving plate is 5-8cm; 50ml 0.5mol / l CaCl 2 The solution is evenly placed in the rotating liquid rec...

Embodiment 2

[0020] Example 2: Sodium alginate-polythiophene (PEDOT) composite oriented conductive hydrogel fiber

[0021] Add different qualities of polythiophene (PEDOT) into deionized water for magnetic stirring and then ultrasonically disperse them. The dispersion power is 300W and the dispersion time is 30-120min to obtain 0.2mg / ml-5mg / ml PEDOT dispersion. 1% sodium alginate and 0.2% PEO were mixed with the above dispersion, and magnetically stirred for 1 h to obtain the electrospinning precursor. Inhale the precursor solution into a 1ml electrospinning syringe and fix it on the propulsion pump, set the propulsion speed to 1-2ml / h, connect the positive pole of the high voltage power supply to the spinning nozzle, and the negative pole to the receiving tray, adjust the electrospinning The distance between the needle and the receiving plate is 5-8cm; 50ml 0.5mol / l CaCl 2 The solution is evenly placed in the rotating liquid receiving tray, and the rotating speed of the receiving tray is...

Embodiment 3

[0022] Example 3: Chitosan-Graphene Composite Oriented Conductive Hydrogel Fiber

[0023] The graphene of different quality and the SDS (sodium dodecyl sulfate) of graphene quality 5% are joined in deionized water and carry out magnetic stirring, then it is placed in ice bath and carry out ultrasonic dispersion, dispersion power is 200W, dispersion time is 30-120min, get 0.2mg / ml-5mg / ml graphene dispersion. Mix 5% chitosan and 0.2% PEO with the above dispersion liquid, carry out magnetic stirring, and obtain electrospinning precursor liquid after dissolution. Inhale the precursor solution into a 1ml electrospinning syringe and fix it on the propulsion pump, set the propulsion speed to 1-2ml / h, connect the positive pole of the high voltage power supply to the spinning nozzle, and the negative pole to the receiving tray, adjust the electrospinning The distance between the needle and the receiving plate is 5-8 cm; 15% NaOH-30% absolute ethanol is evenly placed in the rotating li...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com