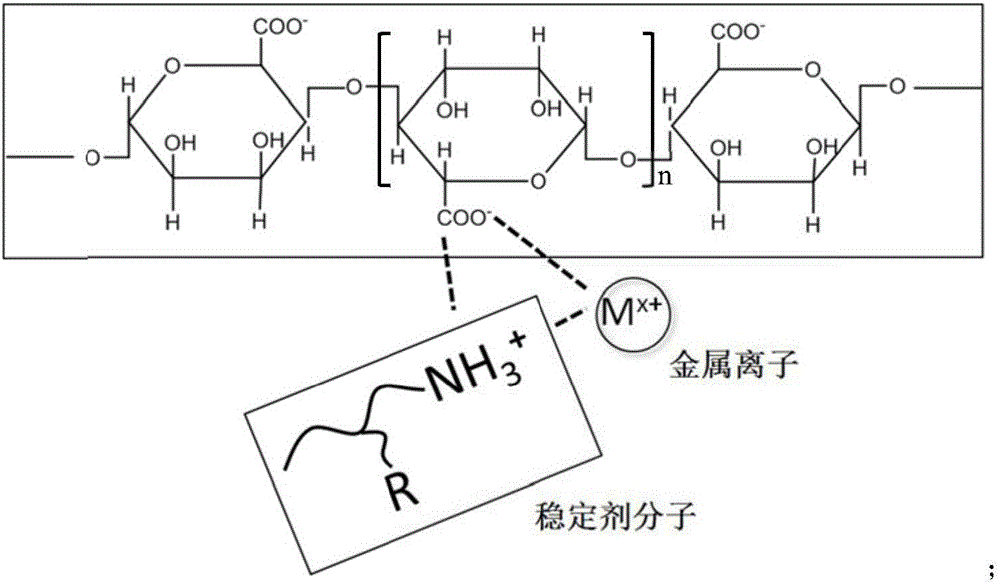

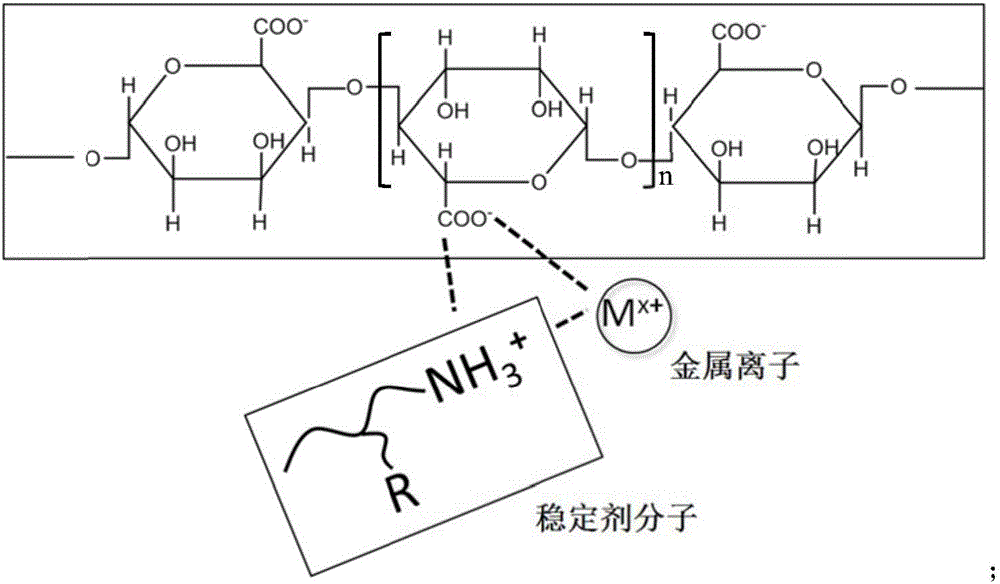

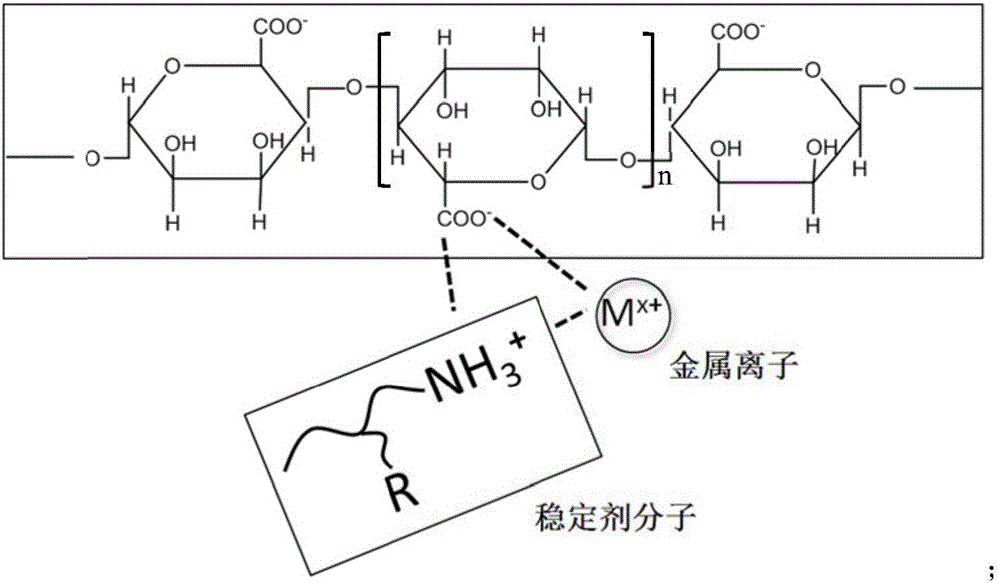

Sodium alga acid flame retardant fibers loaded with metal ions and manufacture method thereof

A sodium alginate and metal-loaded technology, which is applied in the manufacture of fire-resistant and flame-retardant filaments, alginate artificial filaments, wet spinning, etc., can solve problems such as poor stability and poor dispersion of metal nanoparticles, and achieve breaking strength High, easy post-processing, environmental pollution-free effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] A loaded Ag + The preparation method of the sodium alginate flame retardant fiber, under the condition of 20 ℃, the aqueous solution of the sodium alginate with the mass percentage concentration of 0.5% is mixed with the aqueous solution of the n-pentylamine with the mass percentage concentration of 3%, and the sodium alginate and the normal The molar ratio of pentylamine is 1:0.3, and the relative molecular weights of sodium alginate and n-pentylamine are 25000 and 87.16 respectively. When mixing, the pH value of the system is adjusted to 4 with 0.1mol / L HCl solution, and then to AgNO with a concentration of 0.005 g / mL was added dropwise to the mixture 3 Aqueous solution, AgNO 3 The molar ratio to sodium alginate is 0.1:1, stir after the dropwise addition, and the duration is 1h, that is, the loaded Ag + The aqueous solution of the hybrid material of sodium alginate, its mass percent concentration is 0.5%, continuously stirring and adding precipitant ethanol, precipi...

Embodiment 2

[0056] A loaded Fe 2+ The preparation method of the sodium alginate flame retardant fiber, under the condition of 60 ℃, the aqueous solution of sodium alginate with a mass percentage concentration of 0.6% is mixed with the aqueous solution of n-butylamine with a mass percentage concentration of 6%, and the sodium alginate and n-butylamine are mixed. The molar ratio of butylamine is 1:0.7, and the relative molecular weights of sodium alginate and n-butylamine are 250,000 and 73.14 respectively. When mixing, the pH value of the system is adjusted to 6 with 0.15mol / L HCl solution, and then to FeCl with a concentration of 0.2 g / mL was added dropwise to the mixture 2 Aqueous solution, FeCl 2 The molar ratio to sodium alginate is 2.5:1, stir after the dropwise addition, and the duration is 2h, that is, the loaded Fe 2+ The aqueous solution of hybrid material of sodium alginate, its mass percent concentration is 1.2%, continuously stirs and adds precipitant acetone, precipitant ace...

Embodiment 3

[0059] A loaded Fe 3+ The preparation method of the sodium alginate flame retardant fiber, under the condition of 25 ℃, the aqueous solution of sodium alginate with a mass percentage concentration of 1% is mixed with the aqueous solution of polyetheramine D400 with a mass percentage concentration of 4%, and the sodium alginate and The molar ratio of polyetheramine D400 is 1:0.5, and the relative molecular weights of sodium alginate and polyetheramine D400 are 10000 and 400 respectively. When mixing, the pH value of the system is adjusted to 6. Then add FeCl with a concentration of 0.1g / mL dropwise to the mixture 3 Aqueous solution, FeCl 3 The molar ratio to sodium alginate is 0.5:1, stir after the dropwise addition, and the duration is 1.5h, that is, the loaded Fe 3+ The aqueous solution of hybrid material of sodium alginate, its mass percent concentration is 1.5%, continuously stirs and adds precipitant acetone, precipitant acetone and load Fe 3+ The volume ratio of the aq...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Linear density | aaaaa | aaaaa |

| Linear density | aaaaa | aaaaa |

| Linear density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com