Preparation method of sodium alginate nanofiber

A technology of sodium alginate and nanofibers, applied in fiber treatment, spinning solution preparation, fiber chemical characteristics, etc., can solve the problem of lack of entanglement, achieve the effect of increasing the strength of the solution and controlling the diameter of the fiber

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

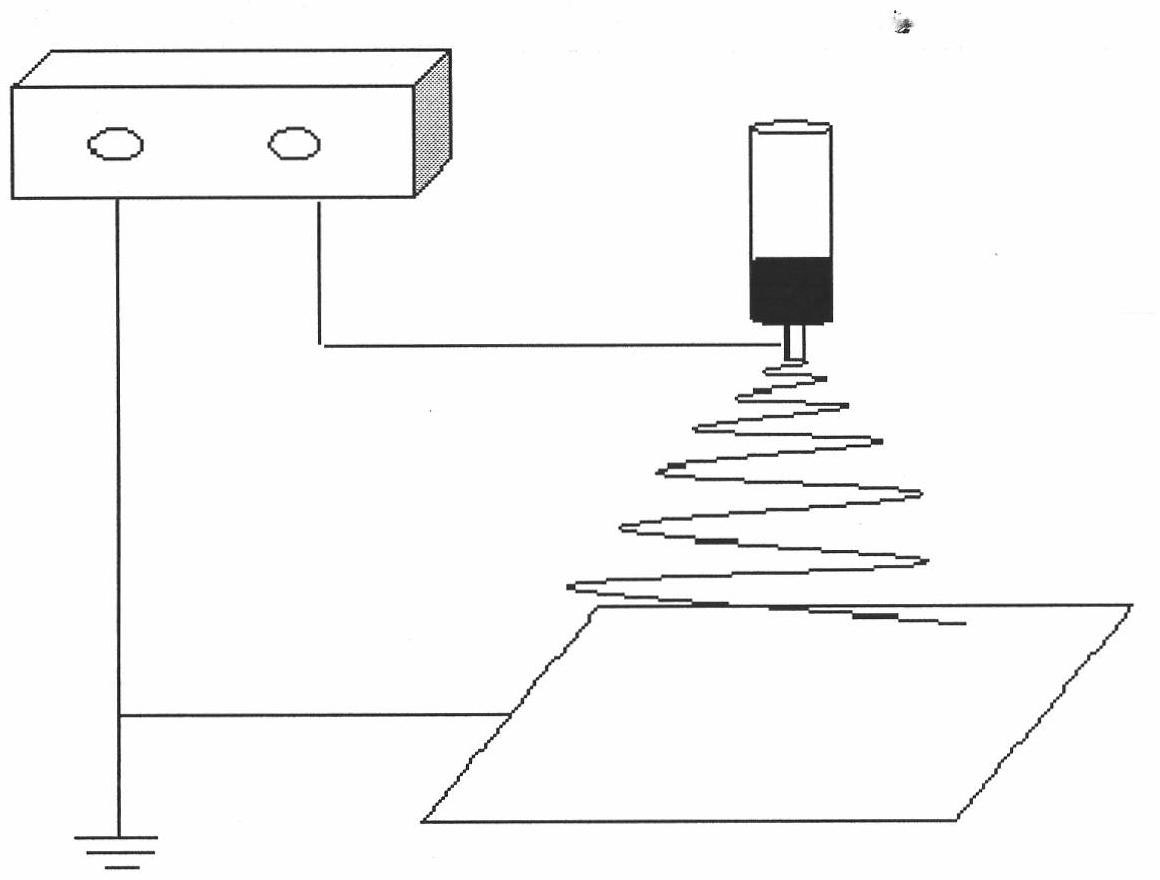

Method used

Image

Examples

Embodiment 1

[0020] 1) preparation concentration is the aqueous solution of the ethanol of 40wt%, the aqueous solution of preparation 20wt% DMF;

[0021] 2) Disperse the sodium alginate SA powder into 40wt% ethanol solution, the SA concentration is 4wt%, stir until the SA is completely dissolved, let it stand until the bubbles escape;

[0022] 3) Add 0.1wt% CaCl to the above SA solution 2 Aqueous to CaCl 2 The content is 2wt% of SA, stir while adding dropwise, let it stand after the dropwise addition is completed, and wait for the bubbles to escape. At this time, the concentration of SA solution is 2.2wt%;

[0023] 4) Add 20wt% N,N-dimethylformamide aqueous solution to SA spinning solution, the mass ratio of N,N-dimethylformamide solution and ethanol solution is 0.5, add water to adjust the concentration of SA to be 1.5wt % as spinning solution;

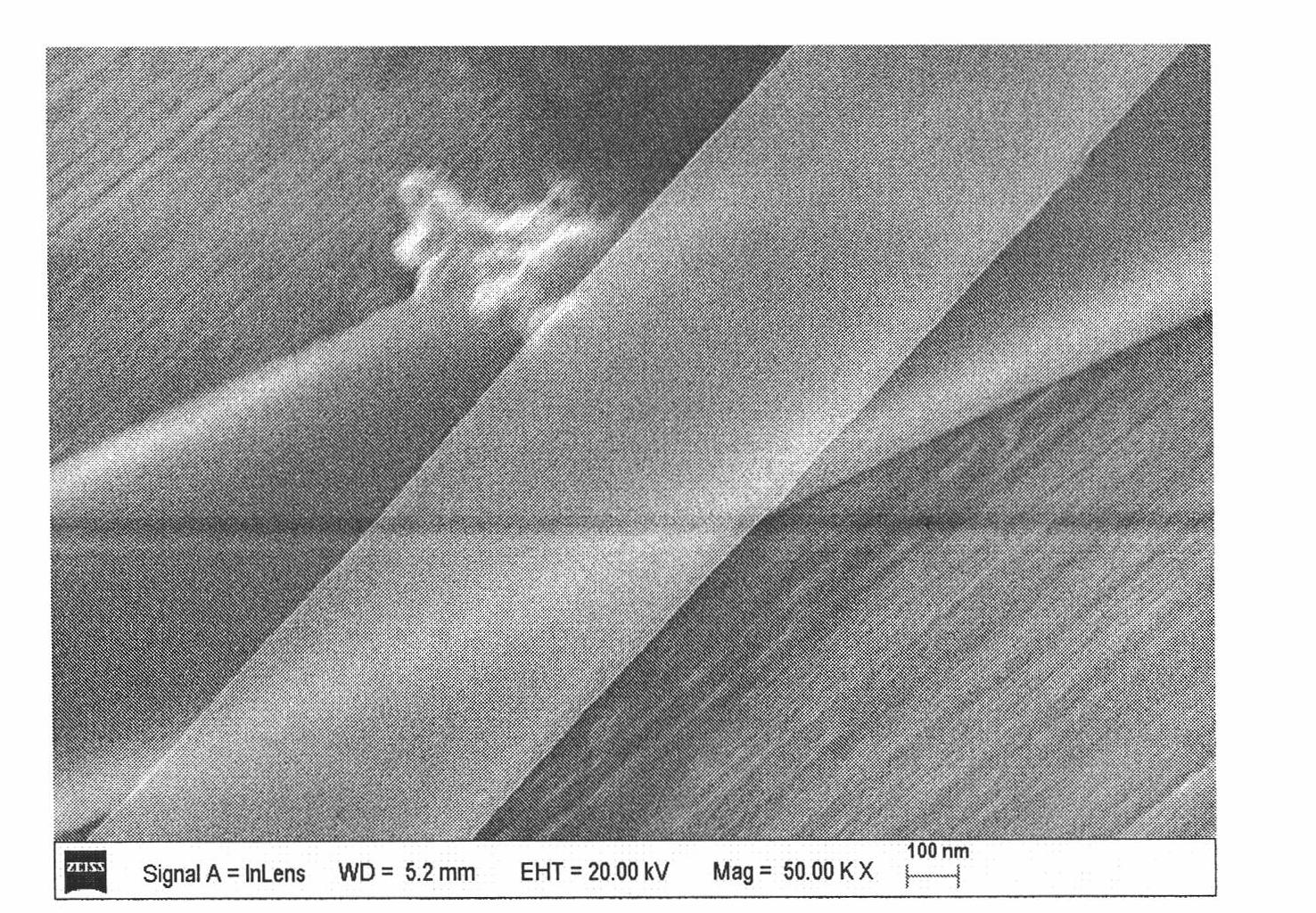

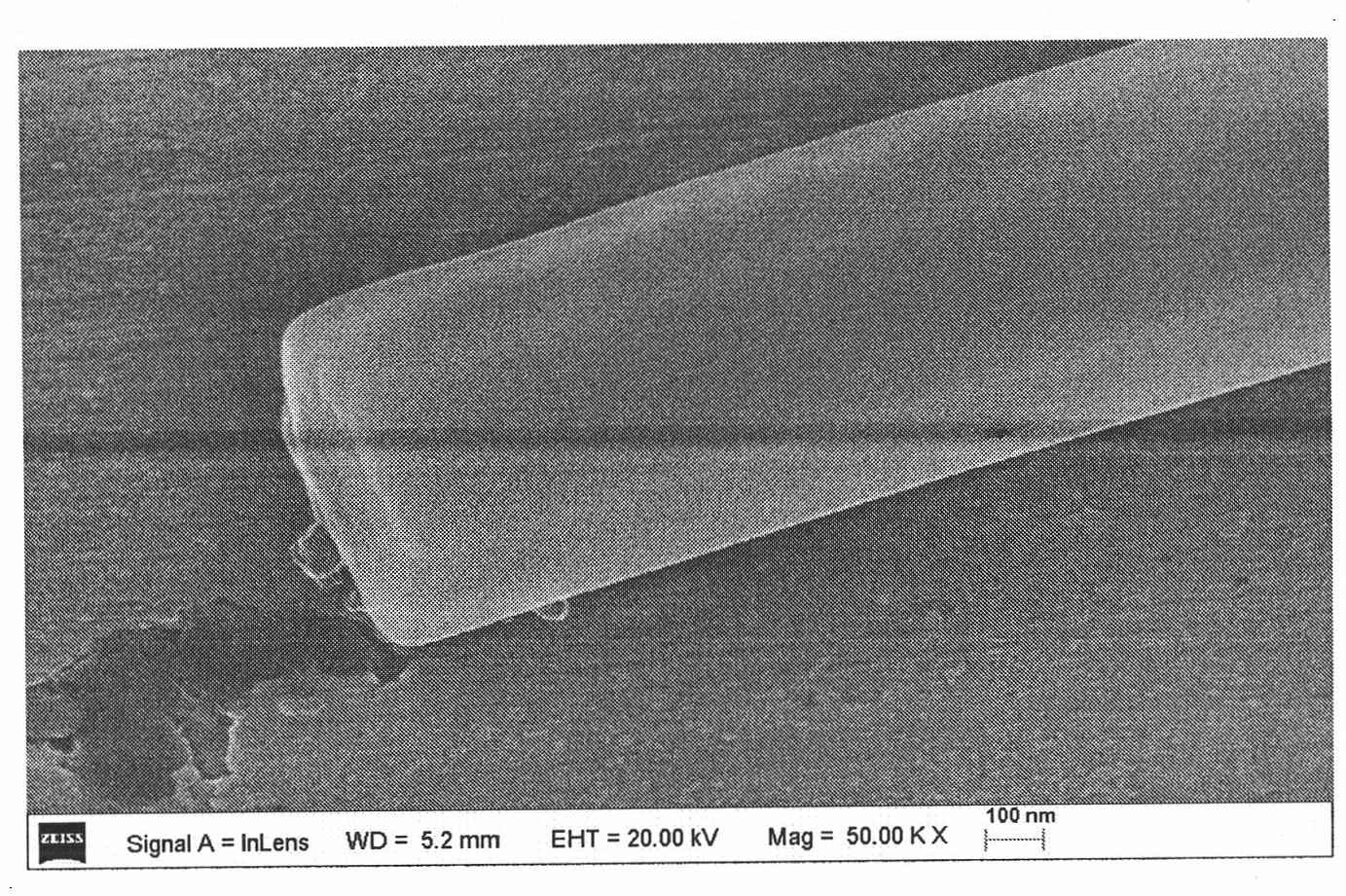

[0024] 5) Add the prepared spinning solution with a concentration of 1.5wt% into the syringe, adjust the voltage to 25kV, the distance from t...

Embodiment 2

[0026] 1) preparation concentration is the aqueous solution of the ethanol of 40wt%, the aqueous solution of preparation 20wt% DMF;

[0027] 2) Disperse the sodium alginate SA powder into a 40wt% ethanol solution, the SA concentration is 6wt%, stir until the SA is completely dissolved, and let it stand until the bubbles escape;

[0028] 3) Add 0.1wt% CaCl to the above SA solution 2 Aqueous to CaCl 2 The content is 2wt% of SA, stir while adding dropwise, let it stand after the dropwise addition is completed, and wait for the bubbles to escape. At this time, the concentration of SA solution is 2.72wt%;

[0029] 4) Add 20wt% N,N-dimethylformamide aqueous solution to SA spinning solution, the mass ratio of N,N-dimethylformamide solution and ethanol solution is 0.5, add water to adjust the concentration of SA to be 2wt% as a spinning solution;

[0030] 5) Add the prepared spinning solution with a concentration of 2wt% into the syringe, adjust the voltage to 25kV, the distance fr...

Embodiment 3

[0032] 1) preparation concentration is the aqueous solution of the ethanol of 20wt%, the aqueous solution of preparation 10wt% DMF;

[0033] 2) Disperse the sodium alginate SA powder into a 20wt% ethanol solution, the SA concentration is 4wt%, stir until the SA is completely dissolved, and let it stand until the bubbles escape;

[0034] 3) Add 0.1wt% CaCl to the above SA solution 2 Aqueous to CaCl 2 The content is 2wt% of SA, stir while adding dropwise, let it stand after the dropwise addition is completed, and wait for the bubbles to escape. At this time, the concentration of SA solution is 2.2wt%;

[0035] 4) Add 10wt% N,N-dimethylformamide aqueous solution to SA spinning solution, the mass ratio of N,N-dimethylformamide solution and ethanol solution is 0.5, add water to adjust the concentration of SA to be 1.5wt % as spinning solution;

[0036]5) Add the prepared spinning solution with a concentration of 1.5wt% into the syringe, adjust the voltage to 25kV, the distance f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com