Cosmetic container for preventing nozzle discharging opening from dripping

The technology of cosmetic container and material outlet is applied in the direction of cosmetic powder container, cosmetic packaging container, dressing container, etc. It can solve the problems of residual material flowing out of nozzle, pollution of household environment, waste of cosmetic material, etc., so as to avoid waste and protect well. The effect of avoiding pollution of the home environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

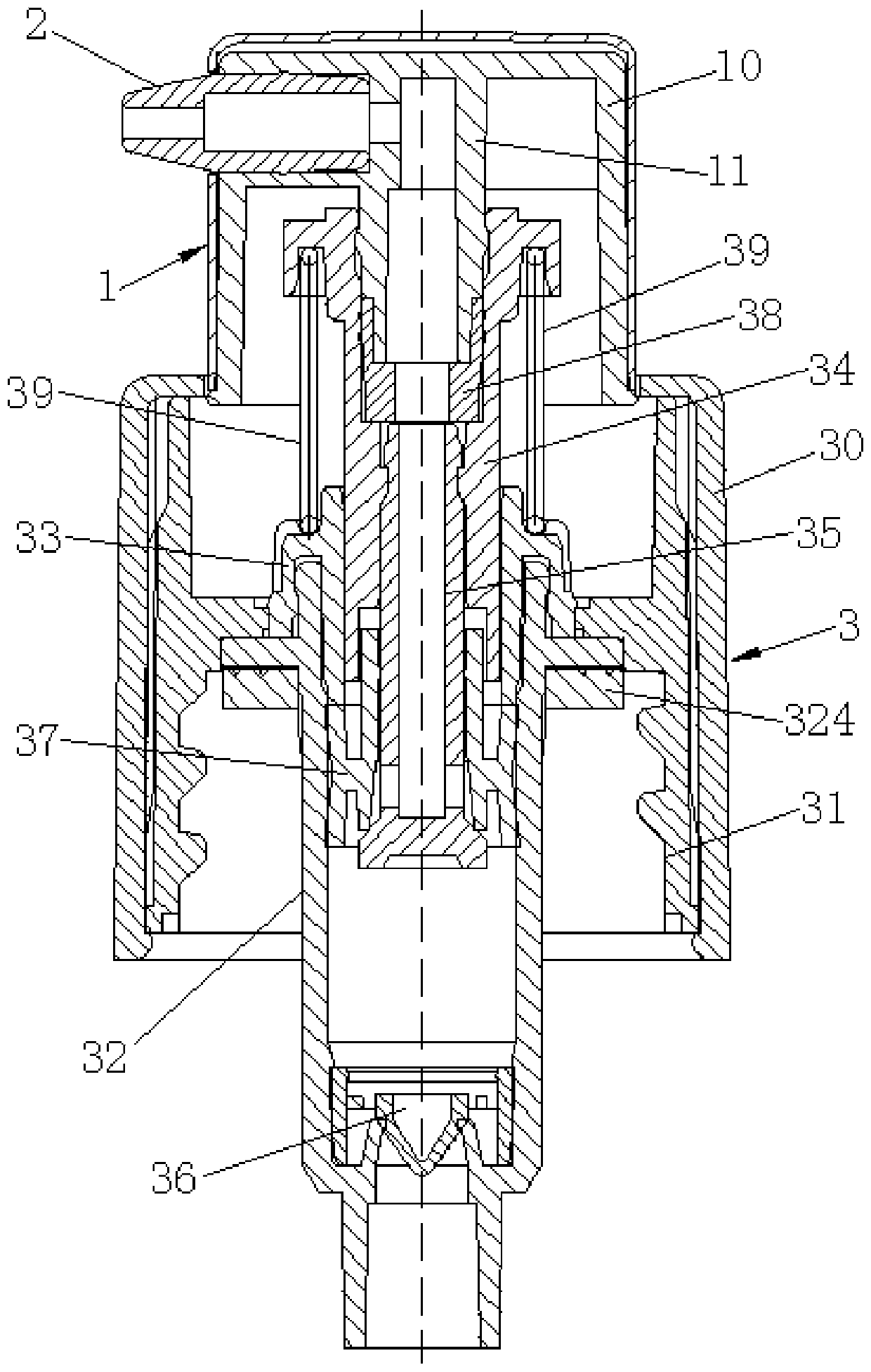

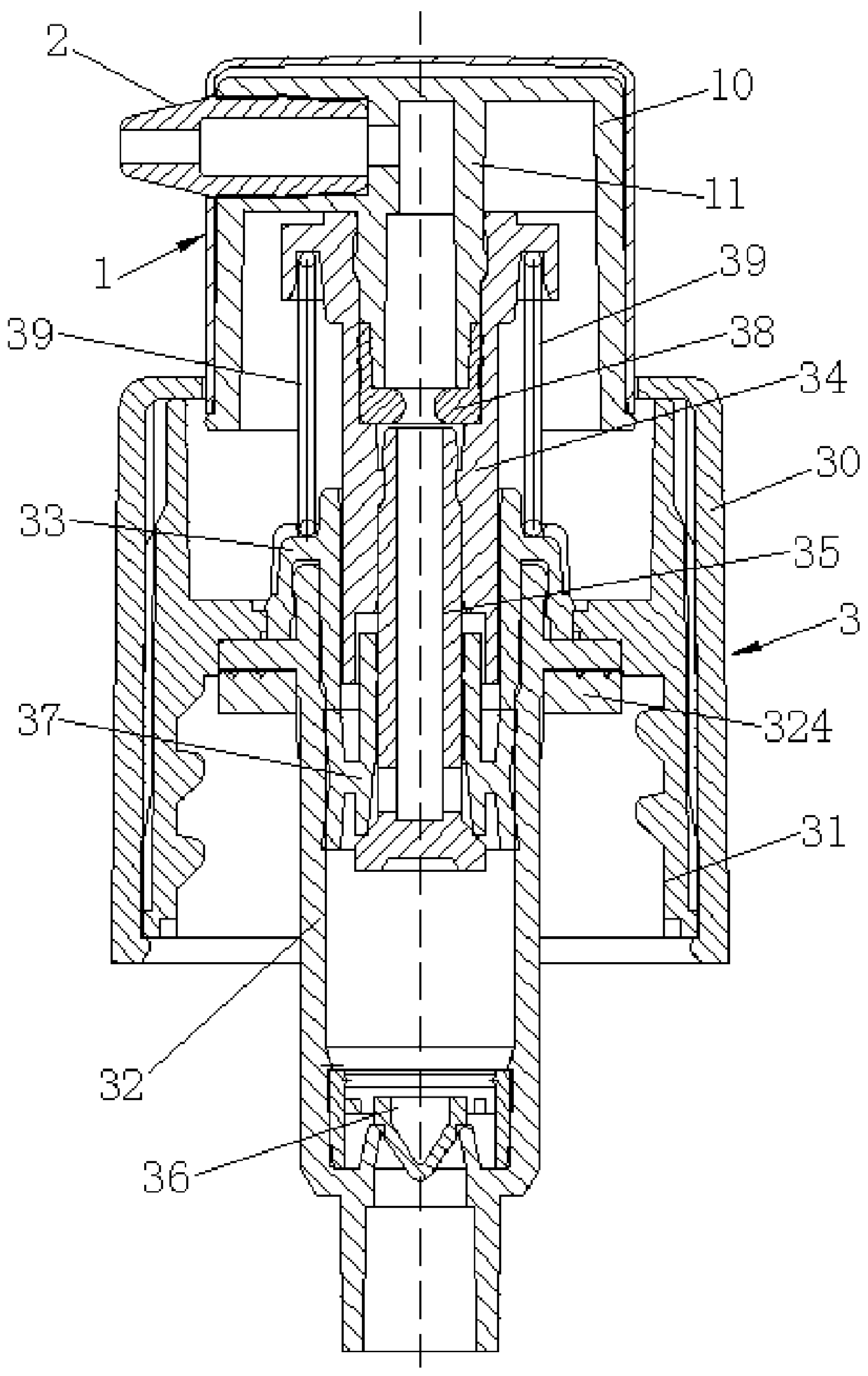

[0067] Please refer to the attached figure 1 And attached figure 2 Shown are the schematic structural diagrams of the first implementation structure of the cosmetic container of the present invention before the button is pressed or after the button rebounds, and the structural schematic diagram of the state when the button is pressed.

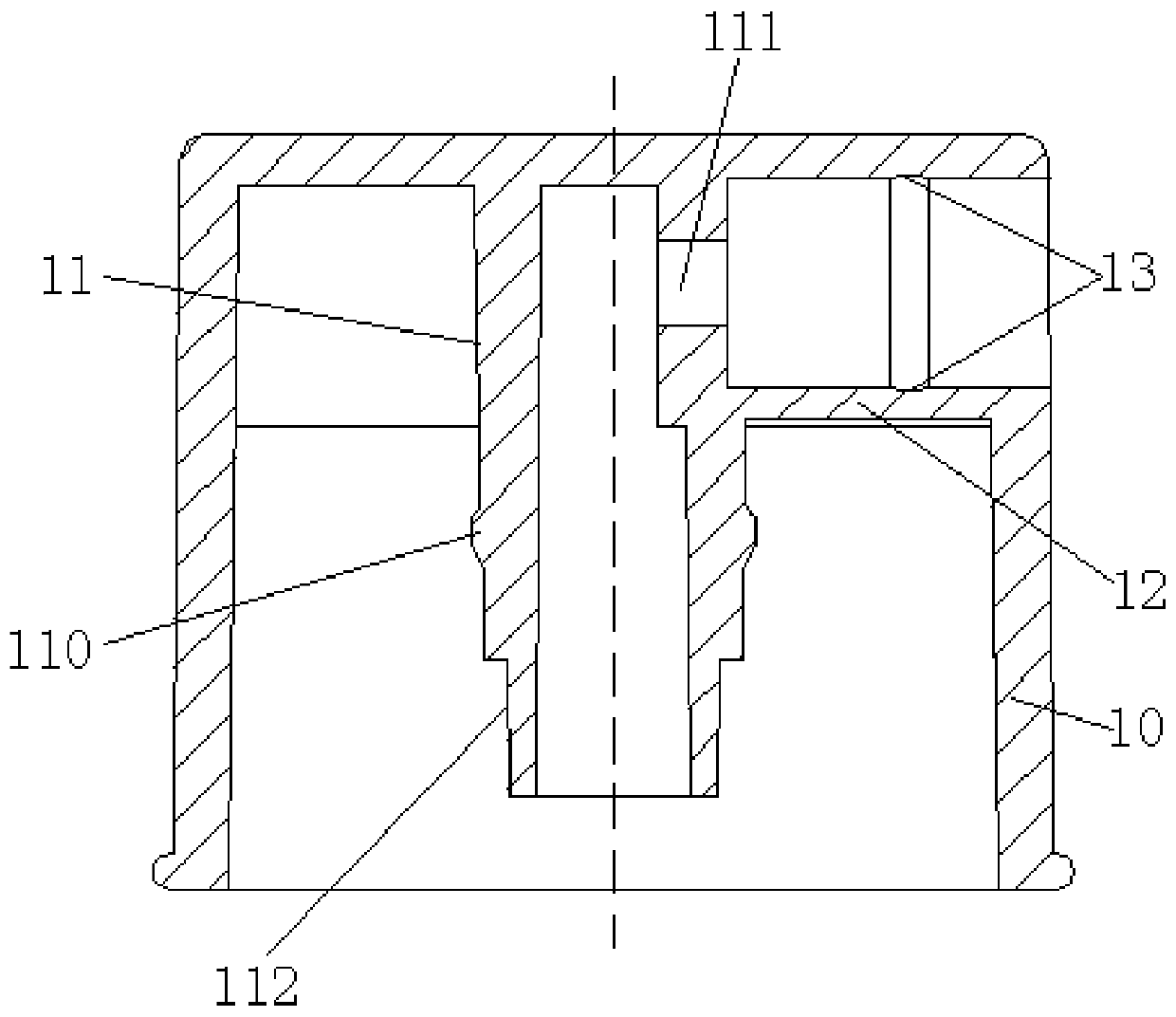

[0068] The cosmetic container for preventing dripping at the outlet of the nozzle includes a button 1, a nozzle 2, a pump assembly 3 and a bottle for containing cosmetic materials. The button 1 has a hollow button body 10 and a positioning built-in The connecting body 11 in the button main body 10 and arranged coaxially with the button main body, and the connecting body 11 is also hollow; the nozzle 2 is positioned and installed in the button main body 10, and the The feed port of the nozzle 2 is also communicated with the inner cavity of the connecting body 11, and the discharge port of the nozzle 2 is also extended outside the button body 1...

Embodiment 2

[0086] Please refer to the attached Figure 14 And attached Figure 15 As shown, the second implementation structure of the cosmetic container of the present invention is a schematic structural diagram of the state before the button is pressed or after the button rebounds, and a schematic structural diagram of the state when the button is pressed.

[0087] Compared with the cosmetic container shown in embodiment 1, the main difference of the cosmetic container shown in embodiment 2 is that the elastic member 38 used in embodiment 2 is different from the elastic member 38 used in embodiment 1.

[0088] In Embodiment 2, the elastic member 38 is a back-suction spring, and the upper part of the back-suction spring is inserted into the connecting body 11 and elastically abuts against the inner wall of the connecting body 11, so The lower part of the suction spring is elastically arranged between the bottom end of the connecting body 11 and the step portion 341;

[0089] In additi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com