Biodegradable super-absorbent non-woven fabric

A biodegradable and superabsorbent technology, applied in wet spinning, non-woven fabrics, spinning solution preparation, etc., can solve problems such as allergies, application, white pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

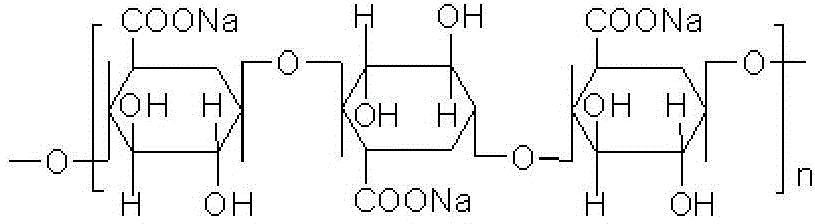

AI Technical Summary

Problems solved by technology

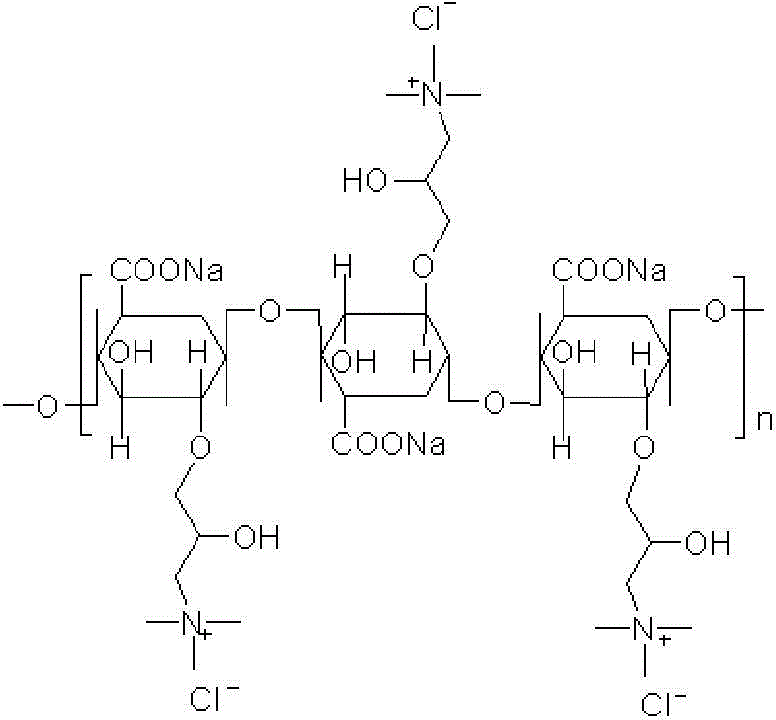

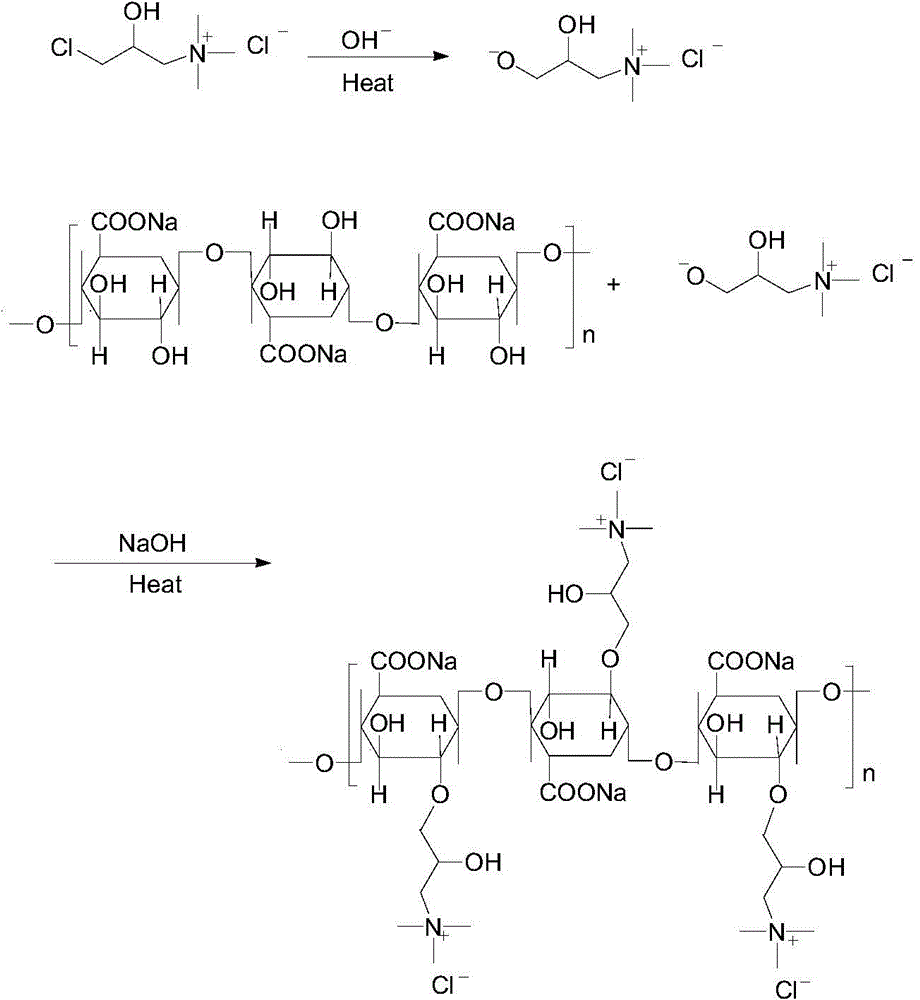

Method used

Image

Examples

Embodiment 1

[0022] Example 1: First prepare 3-chloro-2-hydroxypropyltrimethylammonium chloride, and prepare it into a solution with a mass fraction of 50% for later use; dissolve sodium alginate (molecular weight: 300,000) in the mass fraction In a 5% sodium hydroxide aqueous solution, a sodium alginate solution with a mass fraction of 4% is prepared; a calcium chloride coagulation solution with a mass fraction of 3% is prepared; then the sodium alginate solution is transferred into a reaction kettle, and stirred Heating, stirring at 220 r / min, heating to 60°C, slowly adding 3-chloro-2-hydroxypropyltrimethylammonium chloride solution into the reaction kettle, so that the sugar units on the sodium alginate chain in the solution and the 3 The molar ratio of -chloro-2-hydroxypropyltrimethylammonium chloride is 10:1, and the reaction is completed after stirring for 4 hours at 60°C; the reaction solution is cooled down, degassed under reduced pressure, and the spinning stock solution is obtaine...

Embodiment 2

[0023] Example 2: First prepare 3-chloro-2-hydroxypropyltrimethylammonium chloride, and prepare it into a solution with a mass fraction of 50% for later use; dissolve sodium alginate (molecular weight: 400,000) in a mass fraction of In a 5% sodium hydroxide aqueous solution, a sodium alginate solution with a mass fraction of 5% is prepared; a 5% calcium chloride coagulation liquid is prepared; then the sodium alginate solution is transferred to a reaction kettle, stirred and heated, The stirring rate is 300r / min, heated to 70°C, and slowly adding 3-chloro-2-hydroxypropyltrimethylammonium chloride solution into the reaction kettle, so that the sugar units on the sodium alginate chain in the solution and the 3-chloro- The molar ratio of 2-hydroxypropyltrimethylammonium chloride is 3:1, and the reaction is completed after stirring at 80°C for 12 hours; the reaction solution is cooled down, degassed under reduced pressure, and the spinning stock solution is obtained, and the spinni...

Embodiment 3

[0024] Example 3: First prepare 3-chloro-2-hydroxypropyltrimethylammonium chloride, and prepare it into a solution with a mass fraction of 50% for later use; dissolve sodium alginate (molecular weight: 500,000) in a mass fraction of In a 5% sodium hydroxide aqueous solution, make a sodium alginate solution with a mass fraction of 5%; prepare a 5% calcium chloride coagulation solution; then transfer the sodium alginate solution into a reaction kettle, stir and heat , stirring at a rate of 350r / min, heated to 85°C, and slowly adding 3-chloro-2-hydroxypropyltrimethylammonium chloride solution into the reactor, so that the sugar units on the sodium alginate chain and 3-chloro The molar ratio of -2-hydroxypropyltrimethylammonium chloride is 2:1, and the reaction is completed after stirring for 12 hours at 85°C; % calcium chloride coagulation solution, coagulated at 40°C for 30s to obtain new multifunctional superabsorbent seaweed fibers, and then after stretching, washing, winding,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Square gram weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com