Method for preparing fluorescent fiber membrane

A technology of fluorescent fibers and fluorescent dyes, applied in the fields of chemical characteristics of fibers, preparation of spinning solutions, chemical instruments and methods, etc., can solve the problems of limited variety of dyes, complex synthesis routes, and limited potential for industrial development, and achieve linear optical performance. Excellent, simple synthesis reaction, high yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

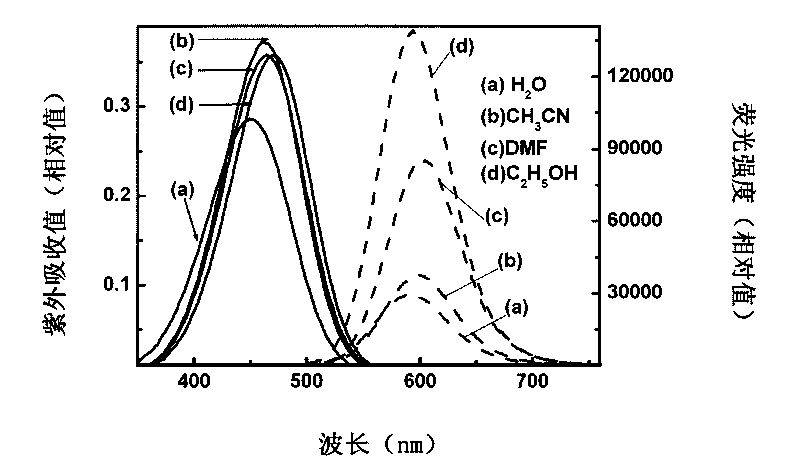

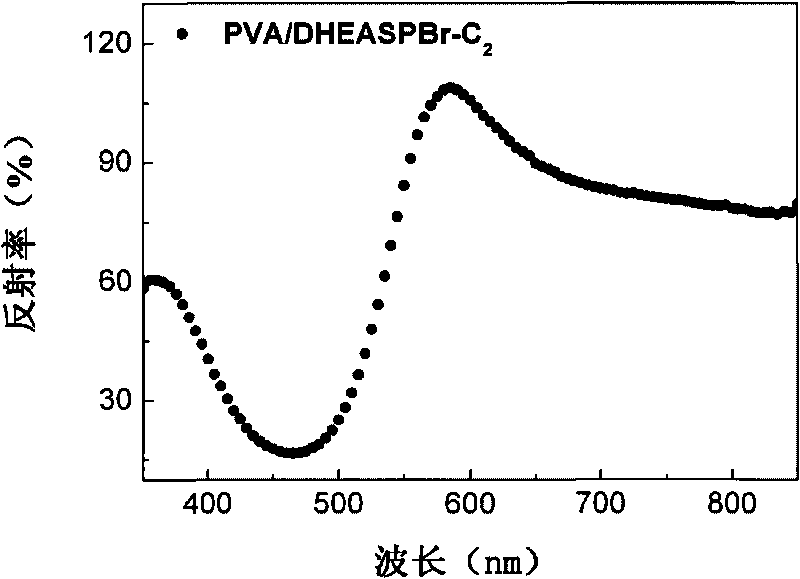

[0029] The preparation of fluorescent dye styrene pyridinium salt specifically relates to trans-4-[4'-(N, N-dihydroxyethylamino) styryl]-N-ethylpyridinium bromide salt (DHEASPBr-C 2 ) preparation:

[0030] (1) 4-N, the synthesis of N-diethanolamine benzaldehyde: Weigh N, N-bishydroxyphenethylamine (0.15mol, 27.189g) and pyridine (0.45mol, 36.43mL) and acetic anhydride (0.45mol, 42.48mL) in a round bottom flask, under N 2 Under protection, reflux and stir the reaction for 5 hours. After the reaction, the solution is poured into ice water, purified with ethyl acetate, and anhydrous MgSO 4 After drying, N,N-diacetoxyphenethylamine was obtained. POCl 3 (0.0876mol, 9.06mL) was poured into the constant pressure funnel, and then 2It was dropped into DMF (0.365mol, 31.63mL) in an ice-bath environment while stirring under protection. After the drop was completed, it was left at room temperature for 30min, and then N,N-diacetoxybenzene dissolved in a small amount of DMF (0.365mol, 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com