Electrostatic spinning nano-fiber film, and preparation method and finger detection method of electrostatic spinning nano-fiber film

A nanofiber membrane and electrospinning technology are applied in the preparation method and the field of fingerprint detection and fiber membrane, which can solve the problems of rapid detection and analysis of unfavorable fingerprints, complicated and cumbersome pretreatment processes, and poor quality of fingerprints, and achieve no toxic and side effects. , The process is fast and convenient, and the fingerprint comparison is clear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] 1. Configuration of spinning solution

[0045] Weigh 0.3323g of fluorescein and dissolve in 23g of DMF / THF solvent, wherein the mass ratio of DMF to THF is 15 / 8. Then 2 g of TPU was added and stirred for several hours until completely dissolved.

[0046] 2. Electrospinning process

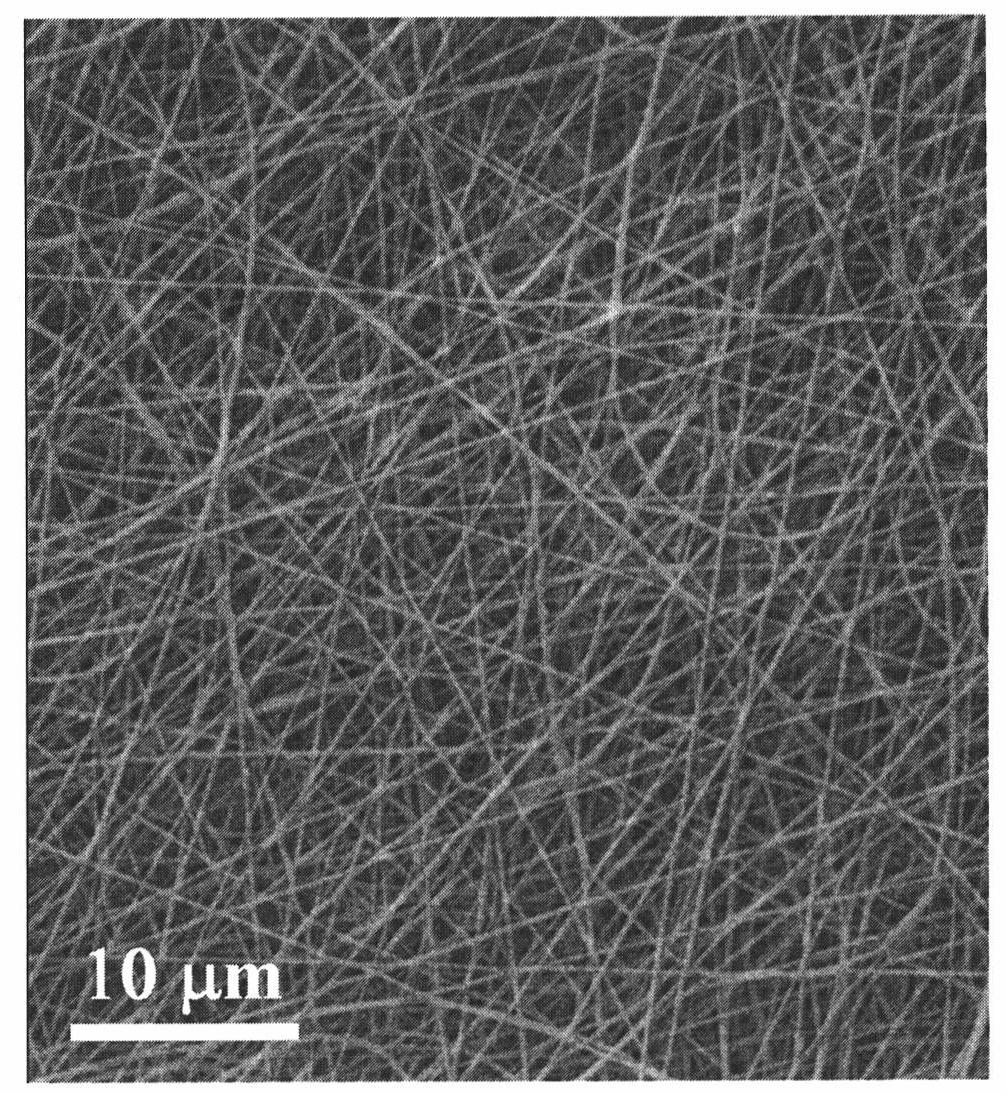

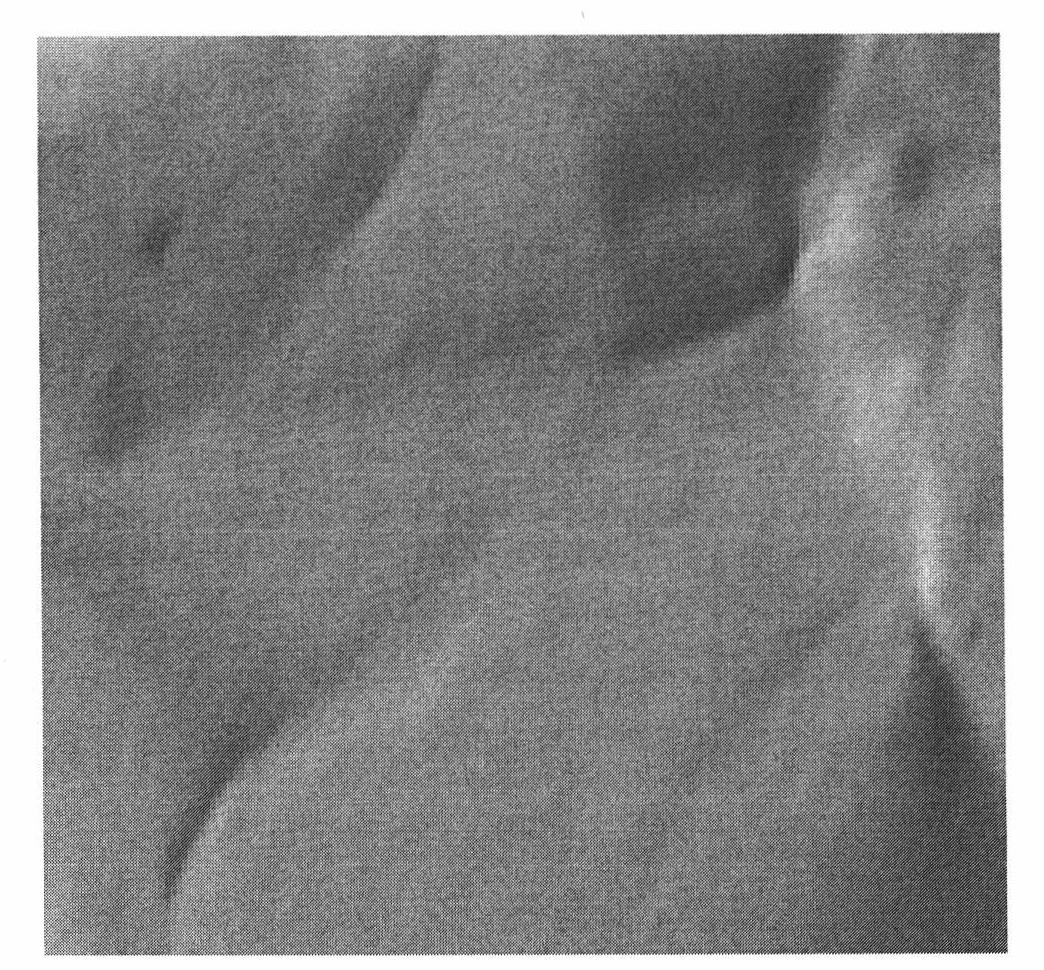

[0047] The spinning solution prepared above was taken for spinning, the flow rate of the spinning solution was 5mL / h, the voltage was 15kV, and the distance between the needle and the drum was 15cm. The obtained spun fiber diameter is uniform, between 200-300nm, the scanning electron microscope picture sees figure 1 . For photos of the fiber membrane see figure 2 .

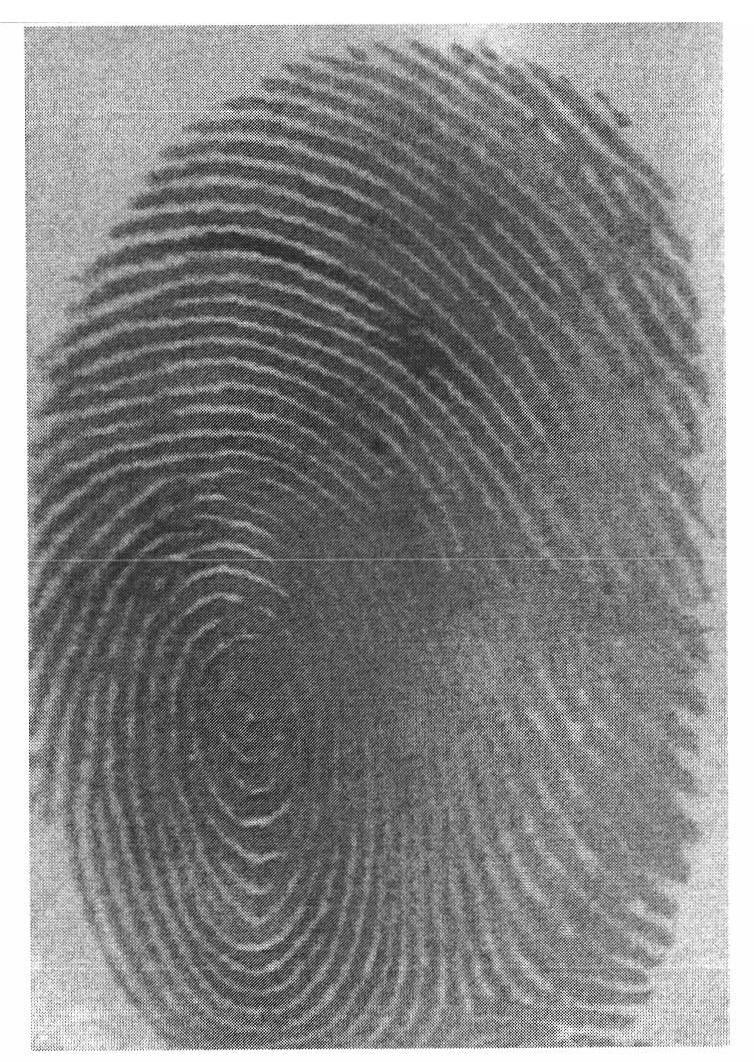

[0048] 3. Fingerprint display

[0049] Fingers are directly touched on the prepared fiber film, leaving latent fingerprints that are easier to distinguish with the naked eye, and then heated with 100 degrees Celsius hot air, and the fingerprints can be clearly identified in an instant (see image 3 ). In addition, the l...

Embodiment 2

[0051] 1. Configuration of spinning solution

[0052] 1 g of fluorescein was weighed and dissolved in 23 g of DMF / THF solvent, wherein the mass ratio of DMF to THF was 15 / 8. Then 2 g of TPU was added and stirred for several hours until completely dissolved.

[0053] 2. Electrospinning process

[0054] The spinning solution prepared above was taken for spinning, the flow rate of the spinning solution was 5mL / h, the voltage was 15kV, and the distance between the needle and the drum was 15cm. The obtained spun fiber diameter is uniform, between 200-300nm, the scanning electron microscope picture sees Figure 5 .

[0055] 3. Fingerprint display

[0056] Put your fingers directly on the prepared fiber film, leaving latent fingerprints that can be distinguished by naked eyes, and then heat it with hot air at 100 degrees Celsius, and the fingerprints can be clearly identified in an instant. In addition, the latent fingerprints on the surface of quartz, glass, stainless steel, po...

Embodiment 3

[0058] 1. Configuration of spinning solution

[0059] 0.02 g of fluorescein was weighed and dissolved in 23 g of DMF / THF solvent, wherein the mass ratio of DMF to THF was 15 / 8. Then 2 g of TPU was added and stirred for several hours until completely dissolved.

[0060] 2. Electrospinning process

[0061] The spinning solution prepared above was taken for spinning, the flow rate of the spinning solution was 5mL / h, the voltage was 15kV, and the distance between the needle and the drum was 15cm. The obtained spun fiber diameter is uniform, between 200-300nm, the scanning electron microscope picture sees Figure 6 .

[0062] 3. Fingerprint display

[0063] Put your fingers directly on the prepared fiber film, leaving latent fingerprints that are difficult to distinguish with the naked eye, and then heat it with hot air at 120 degrees Celsius. After 30 seconds, the fingerprints can be identified. In addition, the latent fingerprints on the surface of quartz, glass, stainless s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com