Active and adaptive photochromic fibers, textiles and membranes

A photochromic and thermochromic technology, applied in fiber processing, fiber chemical characteristics, textiles and papermaking, etc., can solve the problem of reducing the quantum efficiency of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0043] Embodiments include fibers composed of a polymer matrix. In PMMA (M W =540,000) embedded in the following photochromic molecules:

[0044]

[0045] Wherein the average value of n is 7-8.

[0046] DYE3 is of the same formula as DYE1 and where n=1.

[0047] DYE1 shown above is a photochromic backbone polymer comprising 7-8 repeating units (degree of polymerization (DP) = 7-8), while DYE2 shown above is a photochromic molecule with specially selected terminal groups (Stellacci F, Bertarelli C, Toscano F, Gallazzi MC, Zerbi G, CHEM PHYS LETT 302(5-6):563-570, 1999 ("Stellacci")). DYE3 has the same chemical formula as DYE1 and where n=1.

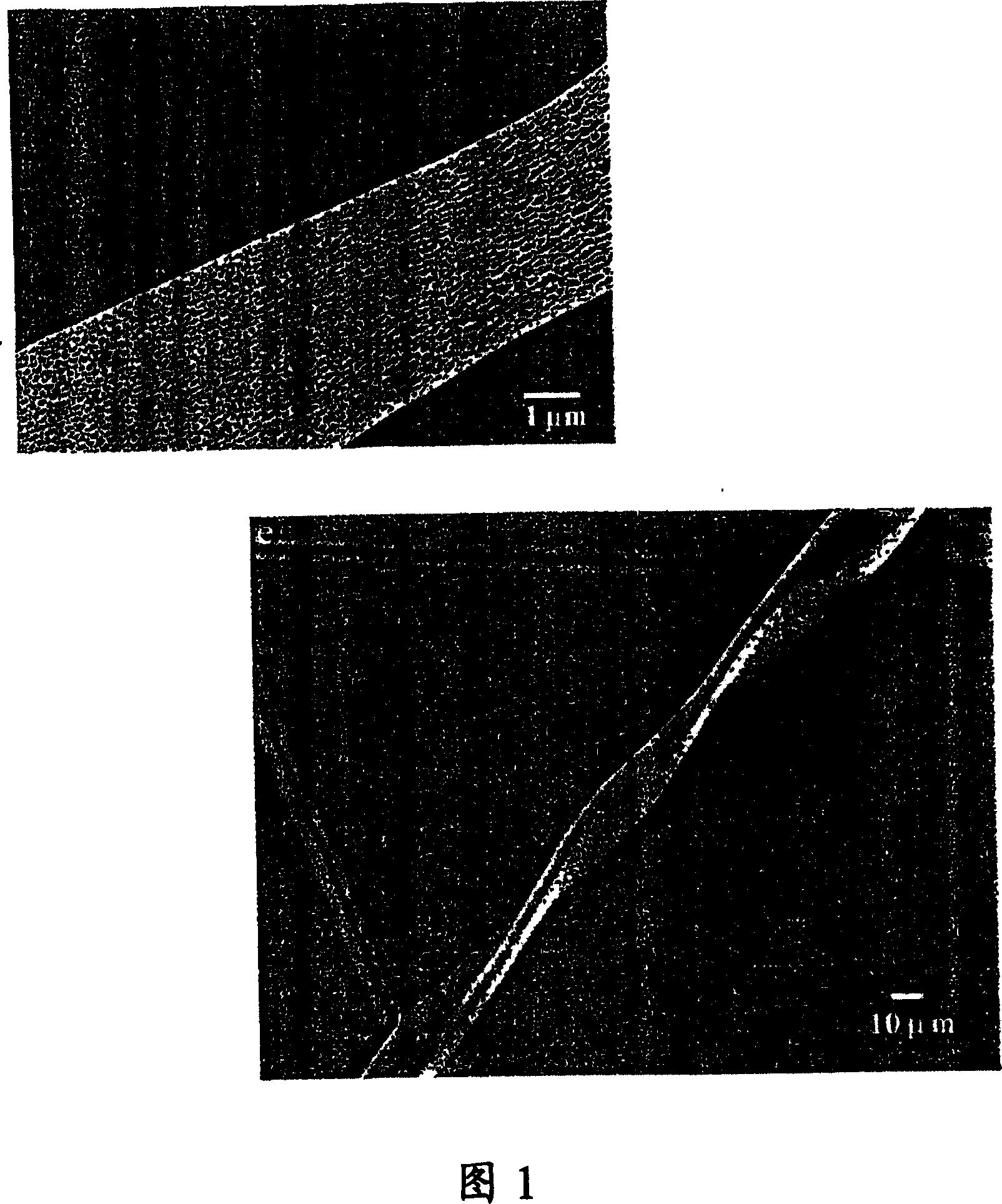

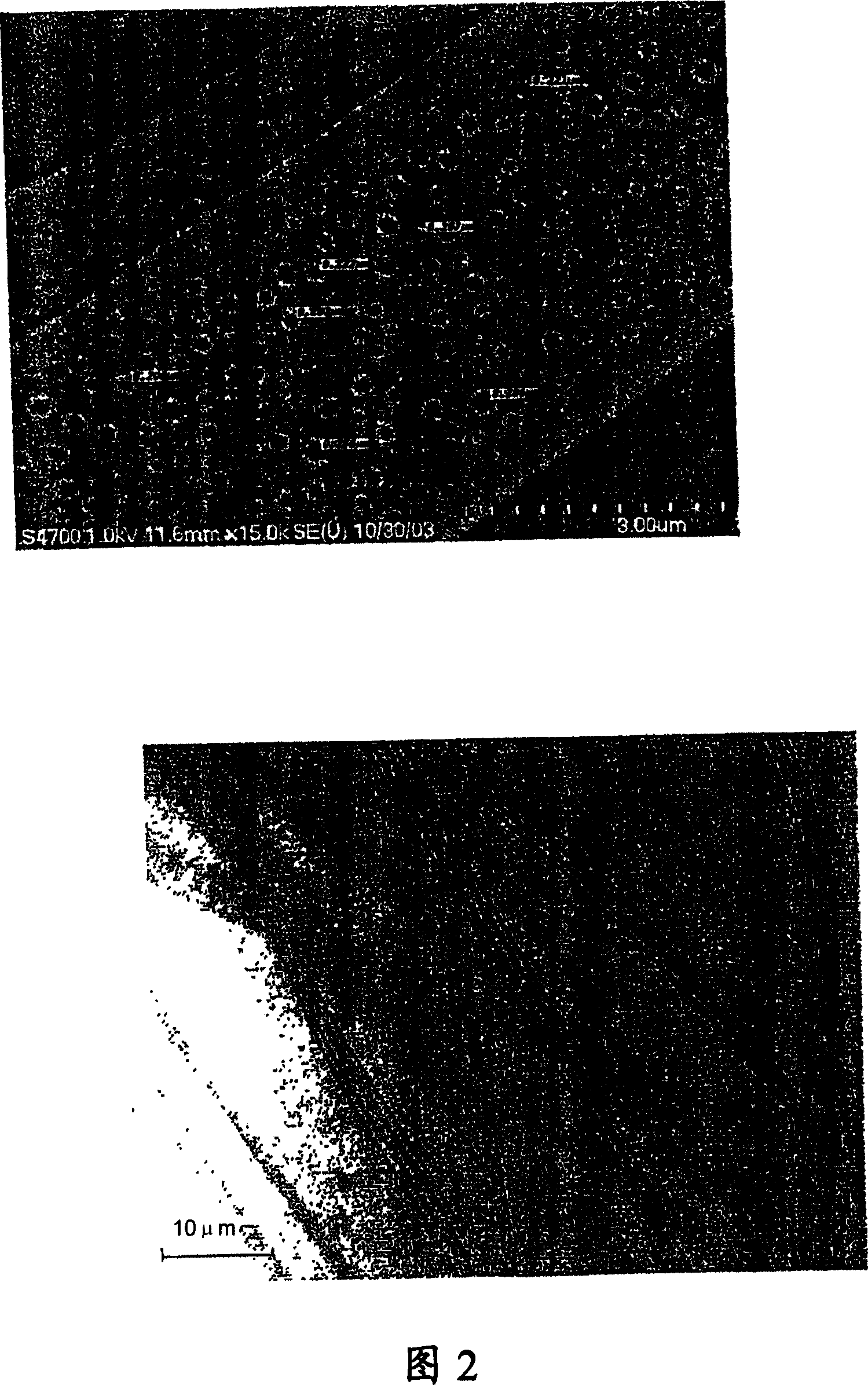

[0048] To prepare electrospun fibers, PMMA and either DYE1 or DYE2 were dissolved in CHCl using specific concentrations as shown in Table 1. 3 middle. The resulting DYE1 (or DYE2)+PMMA solution was then electrospun using the designed treatment scheme. Specific parameters used for the first set of experiments described below are s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com