Preparation method of flat acrylic fiber

An acrylic fiber and flat technology, which is applied in the field of acrylic fiber preparation, can solve the problems of insufficient application in actual production needs, etc., and achieve the effect of strong rigidity, good spinnability, and soft hand feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

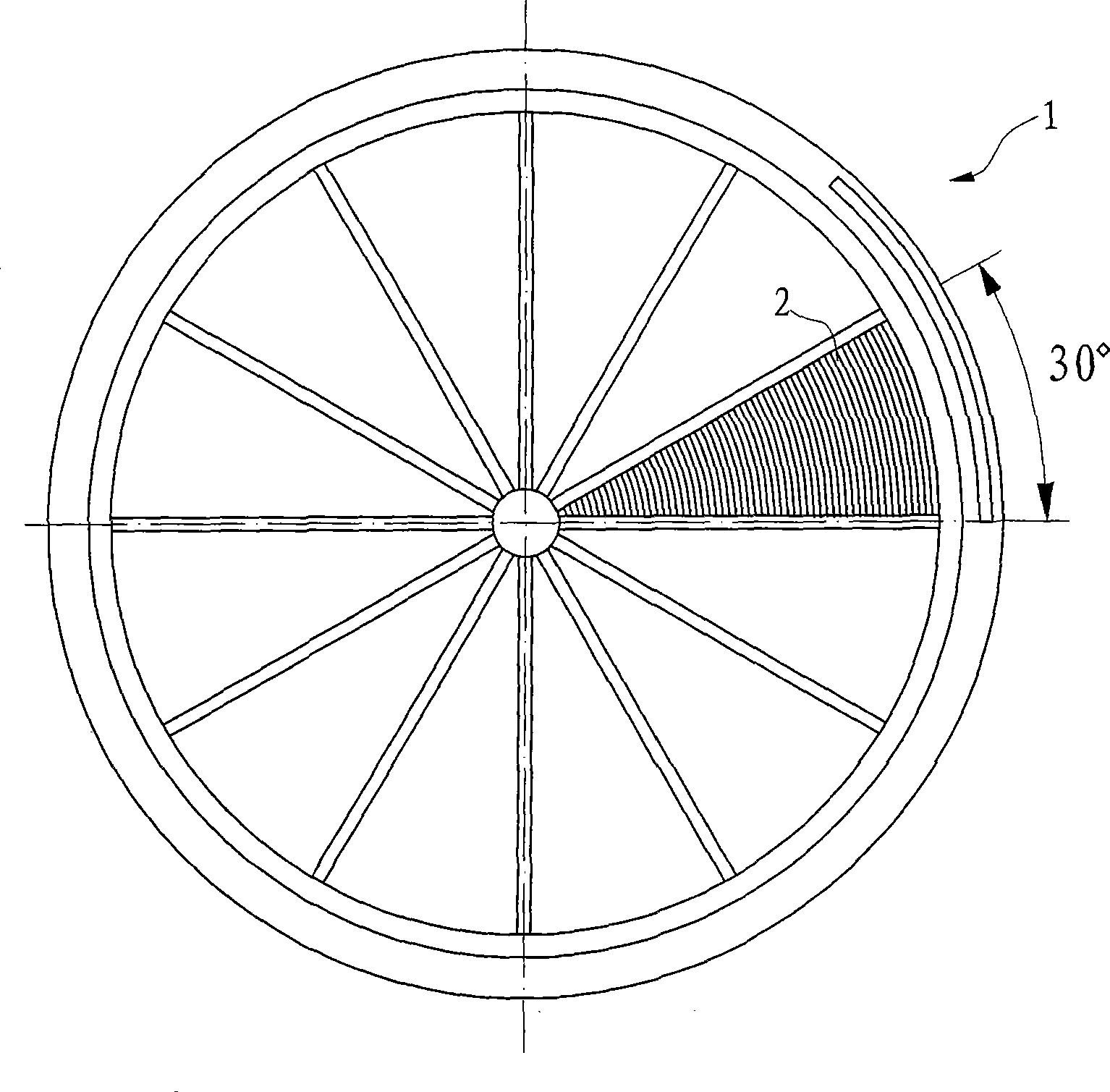

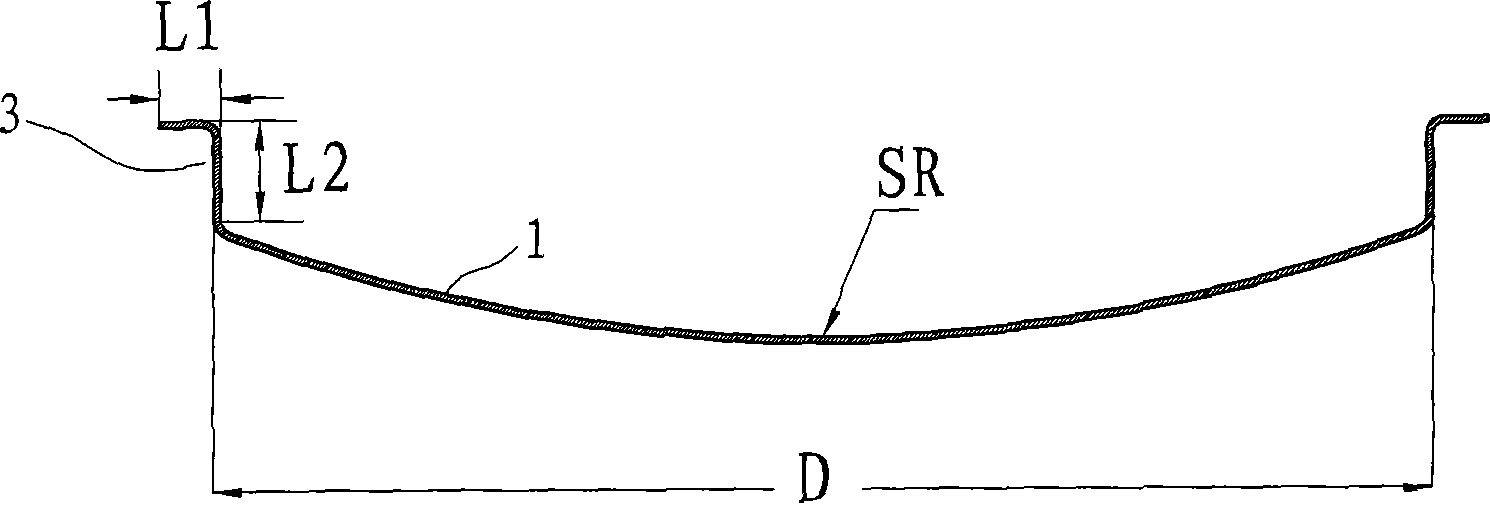

[0027] Embodiment: the preparation method of the flat acrylic fiber in the present embodiment is characterized in that comprising the following steps successively:

[0028] a. Spinning and molding to obtain primary fiber: use polyacrylonitrile dry powder as raw material, and use dimethylacetamide as solvent to prepare a polymer stock solution with a mass percentage concentration of 23-26%. After being heated by a heater, it is sprayed The monofilament is extruded from the special-shaped spinneret holes on the wire board, the heater temperature is controlled at 120-130°C, the glue supply is controlled at 50-60 rpm, the pre-spinning pressure is controlled at 450-700Kpa, and the coagulation bath temperature is 35 ~45°C, the mass percentage concentration of dimethylacetamide in the coagulation bath is 51-54%, and the circulation rate of the coagulation bath is 15000-35000kg / h;

[0029] b. Washing and drawing: the prepared primary fiber is washed and drawn, the temperature of the d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com