Preparation method of anti-pilling acrylic fiber

An anti-pilling acrylic fiber and fiber technology, which is applied in fiber treatment, fiber chemical characteristics, spinning solution preparation, etc., can solve the problem that the anti-pilling performance of fibers can not be satisfied, and the anti-pilling performance level can only reach 3~4 and other problems to achieve the effect of improving dyeing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

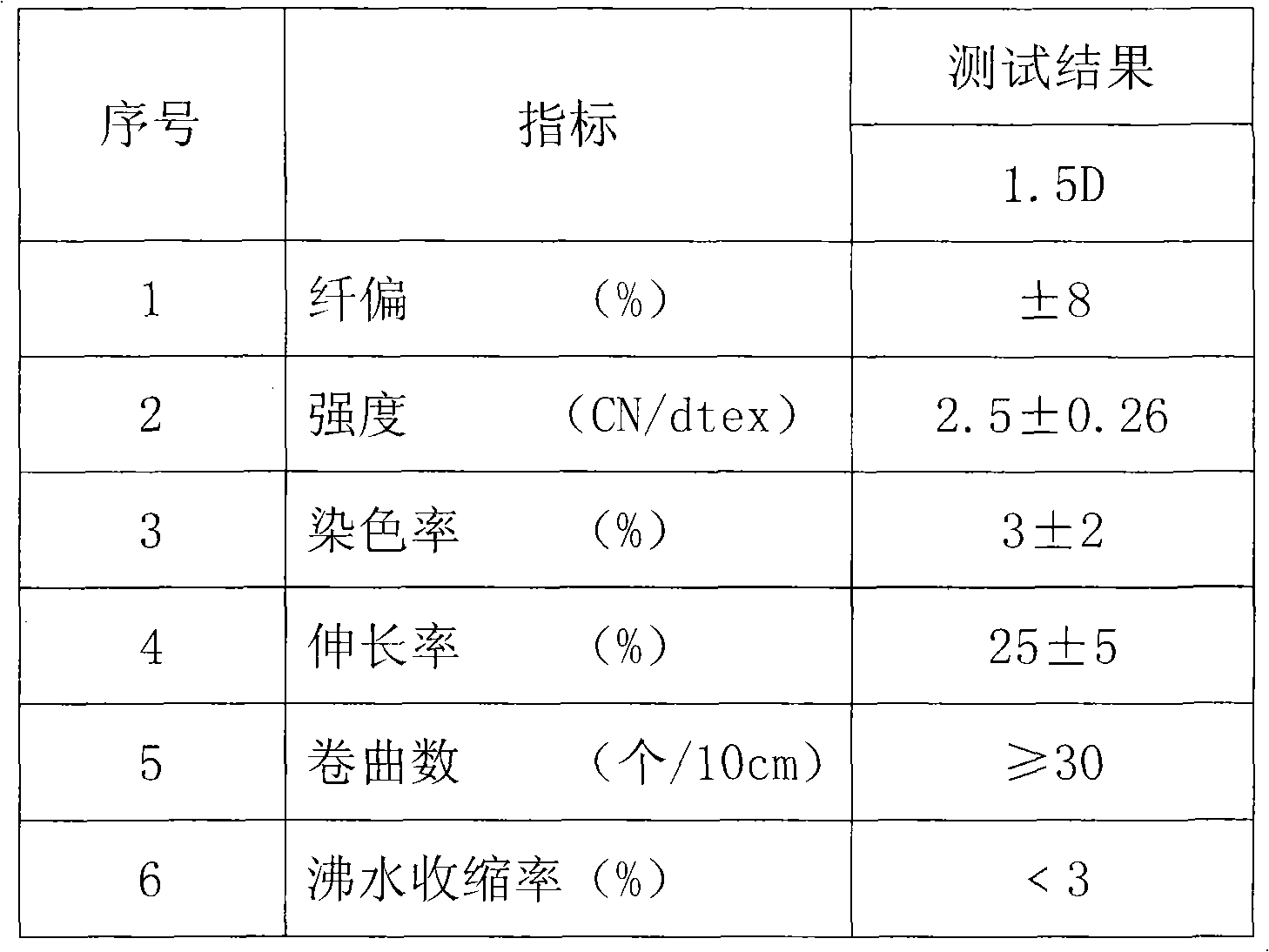

Embodiment 1

[0015] A preparation method of anti-pilling acrylic fiber, mixing three monomers of 93.5wt% acrylonitrile, 6.05wt% vinyl acetate and 0.45wt% sodium methacrylate sulfonate, and adjusting the concentration after mixing to 30-40wt% , at 58-62°C, pH 2.5-3.5, continuously carry out aqueous phase suspension polymerization reaction; the reacted polymer is terminated by chelation reaction, the unreacted monomer is removed by a stripper, and then the salt is removed by washing and filtering , water, after granulation and drying, the powdery polymer of 35000-50000 is mixed and dissolved with dimethylacetamide (DMAC), heated to 85±2°C, cooled to 75±2°C, and filtered to obtain The spinning stock solution is spun at a pressure of 0.7-0.9MPa and a temperature of 90-95°C after temperature and pressure adjustment and filtration. The concentration of the DMAC coagulation bath is 40-50wt%, and the temperature of the coagulation bath is 38-50°C. After double-diffusion molding, washing, oiling, d...

Embodiment 2

[0017] Example 2 The monomer composition is: 94wt% acrylonitrile, 5.65wt% vinyl acetate, 0.35wt% sodium methacrylate; the spinning setting pressure is 150KPa. Embodiment 3 The monomer composition is: 94.5wt% acrylonitrile, 5.25wt% vinyl acetate, 0.25wt% sodium methacrylate; the spinning setting pressure is 200KPa. Same as Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com