Treatment technology for acrylic fibers waste water by dry process

A dry-process acrylic fiber and treatment process technology, applied in the field of multi-stage treatment of industrial wastewater, can solve the problems of harsh methane production control conditions, high impact, long process routes, etc., achieving easy industrial implementation, reducing operation difficulty, and improving treatment effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

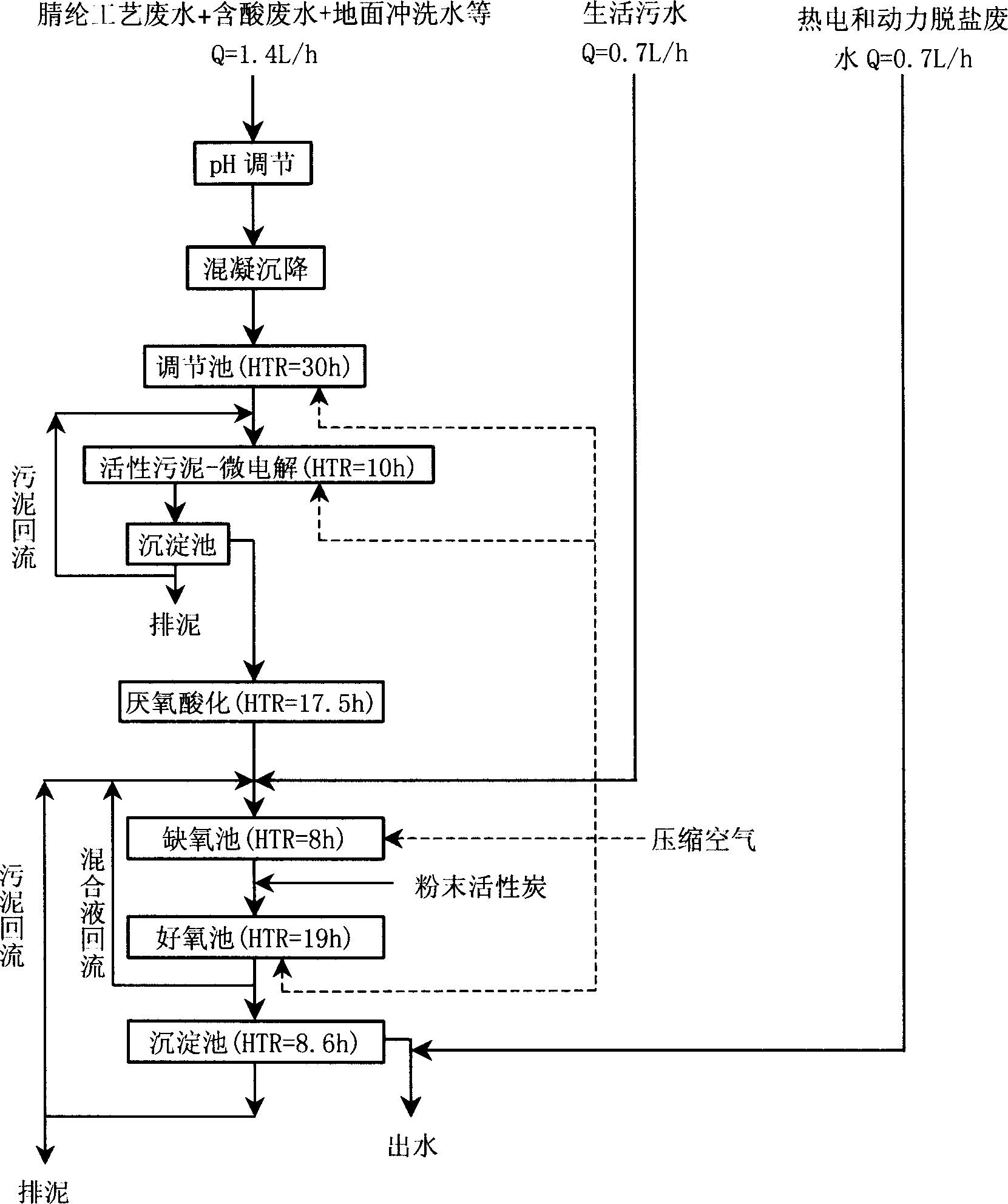

[0052] Example 1 Normal program processing

[0053] according to figure 1 The technical process is carried out. After the dry process acrylic fiber process wastewater is mixed with acid-containing wastewater and ground washing water, the wastewater condition is: COD is 1500mg / L, BOD is 450mg / L, ammonia nitrogen is 45mg / L, turbidity is 50mg / L, pH The temperature is 6.3, the temperature is 85-90°C, the EDTA is 180mg / L, the sulfate is 320mg / L, and the sulfite is 580mg / L. Adjust the pH to 7.5 with lime for coagulation-sedimentation.

[0054] In the coagulation-sedimentation unit, the flocculant added is 100 mg / L of commercial polyaluminum (namely polyaluminum chloride Aluminum polychloride) and 0.8 mg / L of cationic polymer flocculant (commercial CP-937). Coagulation-sedimentation effluent COD is 1400mg / L, BOD is 450mg / L, ammonia nitrogen is 45mg / L, turbidity is 7.5mg / L, pH is 7.3, temperature is 60°C, EDTA is 180mg / L, sulfate radical is 340mg / L L, sulfite is 300mg / L. The supe...

Embodiment 2

[0058] Example 2 The sequence of activated sludge-micro-electrolysis unit and coagulation-sedimentation unit is interchanged

[0059] according to figure 1 The technical process is carried out. After the dry process acrylic fiber process wastewater is mixed with acid-containing wastewater and ground flushing water, the wastewater condition is: COD is 1800mg / L, BOD is 550mg / L, ammonia nitrogen is 25mg / L, turbidity is 80mg / L, pH The temperature is 7.3, the temperature is 85-90°C, the EDTA is 260mg / L, the sulfate is 470mg / L, and the sulfite is 880mg / L. Use lime to adjust the pH to 7.5 and first perform activated sludge-micro-electrolysis.

[0060] In the activated sludge-micro-electrolysis unit, carbon steel pendants are installed in the activated sludge system, the pH is controlled at 6.5-7.5, the hydraulic retention time is 12h, the dissolved oxygen is 5-7mg / L, the sludge concentration is 4g / L, and the sludge retention Time 10d, sludge reflux ratio 200%. Activated sludge-mi...

Embodiment 3

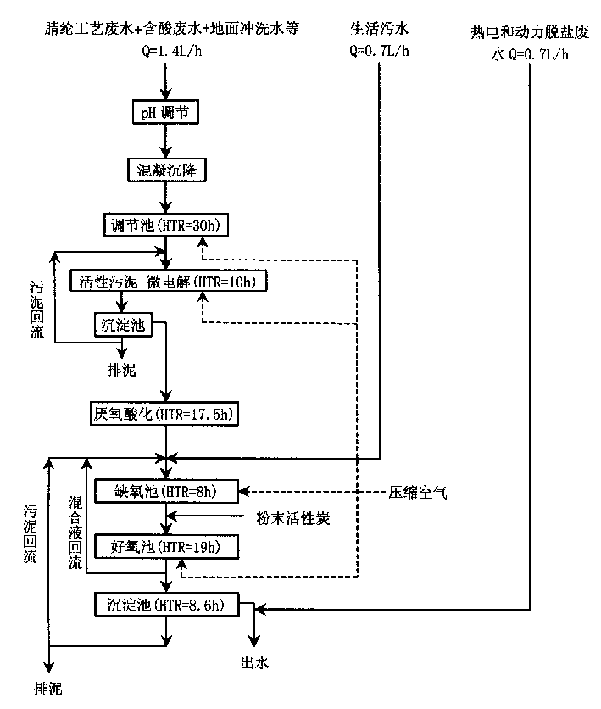

[0062] Example 3 The sequence of activated sludge-micro-electrolysis unit and coagulation-sedimentation unit is interchanged

[0063] In the activated sludge-micro-electrolysis unit, the pH is controlled at 6.5-7.5, the hydraulic retention time is 18h, the dissolved oxygen is 0.5-1mg / L, the sludge concentration is 4g / L, the sludge residence time is 10d, and the sludge reflux ratio is 50%.

[0064] In the coagulation-sedimentation unit, the flocculant added is 30 mg / L of commercial polyaluminum and 0.3 mg / L of cationic polymer flocculant (CP-937). The rest are the same as example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com