Bamboo carbon fiber blanket material and finished products thereof

A bamboo carbon fiber and blanket technology, applied in textiles and papermaking, weft knitting, yarn, etc., can solve the problems of poor spinnability, high cost, and little function, and achieve carbon density, moderate price, and strong adsorption and decomposition capabilities Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1: making bamboo carbon fiber Raschel blanket

[0033] The knitting chain yarn is made of one or several types of 100-250D / 36F FDY base polyester filament, 100-250D / 48F FDY base polyester filament, and 100-250D / 96F FDY base polyester filament. into; weaving with the filament can meet the technological requirements of the blanket with low cost and high production efficiency. The finer the total fineness and the more the number of single fibers, the softer the blanket; too fine will affect the tensile breaking strength of the blanket.

[0034] Inserted weft yarn is woven from one or several kinds of 100~250D / 36F FDY base material polyester filament, 100~250D / 48F FDY base material polyester filament, 100~250D / 96F FDY base material polyester filament . The blanket woven with the polyester filaments of the above specifications as the weft-inserted yarn has relatively stable dimensions. If it is too thin, it will affect the strength and dimensional stability. Al...

Embodiment 2

[0041] Embodiment 2: making bamboo carbon fiber Raschel blanket

[0042] The composition of the weight percentage described in number 2 in Table 1 is selected as raw material, and other processes are the same as in Example 1, so no further details are given.

Embodiment 3

[0043] Example 3: Making Acrylic Bamboo Carbon Fiber Blanket

[0044] The base material is woven from one of the specifications of 100-250D / 36F FDY polyester filament, 100-250D / 48F FDY polyester filament, and 100-250D / 96F FDY polyester filament. Weaving with the filaments can meet the technical requirements of the blanket, and has low cost and high production efficiency. The finer the total fineness and the more the number of single fibers, the softer the blanket; too fine will affect the tensile breaking strength of the blanket.

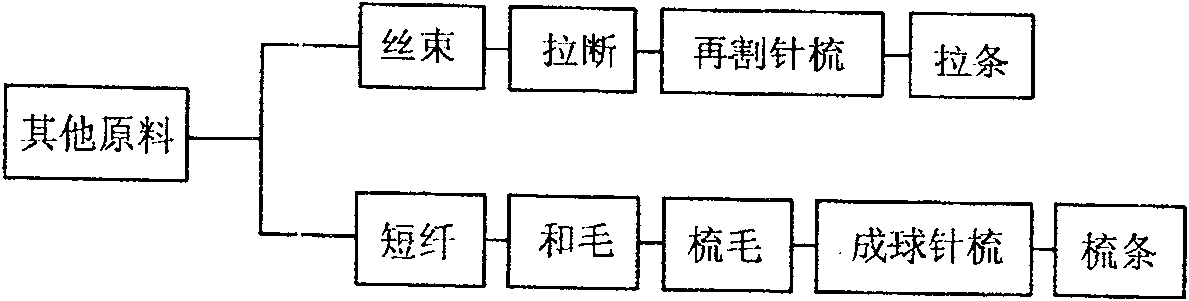

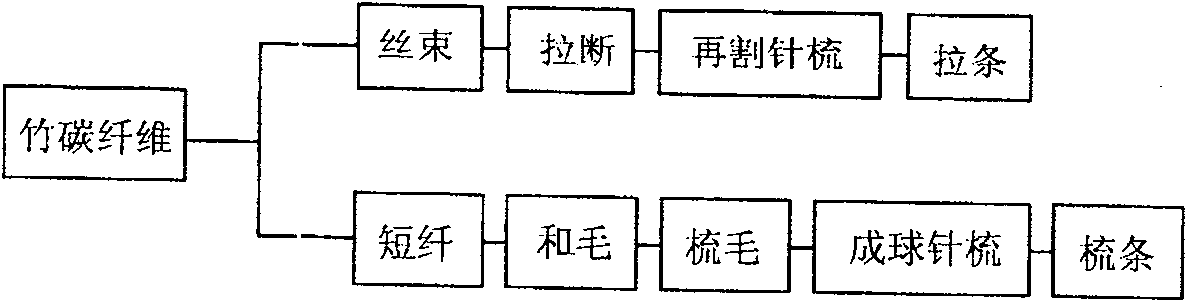

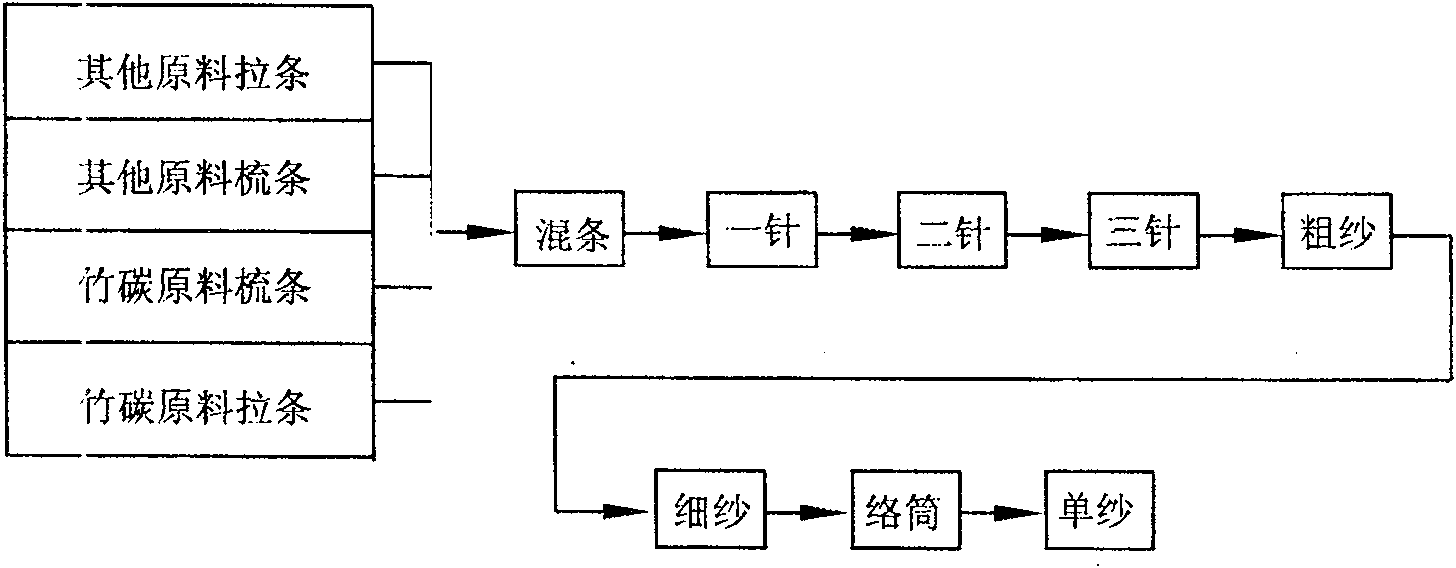

[0045] The plush yarn is made by blending the bamboo carbon fiber with the number 3 weight percent in Table 1 and other raw materials with a specification of 10-16Nm single yarn. The production process of the single yarn is as follows: figure 1 with image 3 shown; then the plush yarn and the ground yarn are woven together into a bamboo carbon fiber acrylic blanket white gray cloth by a weft knitting machine.

[0046] Cut the bamboo carbon fiber ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com