Moisture-absorbing smell-absorbing composite material, and preparation method thereof

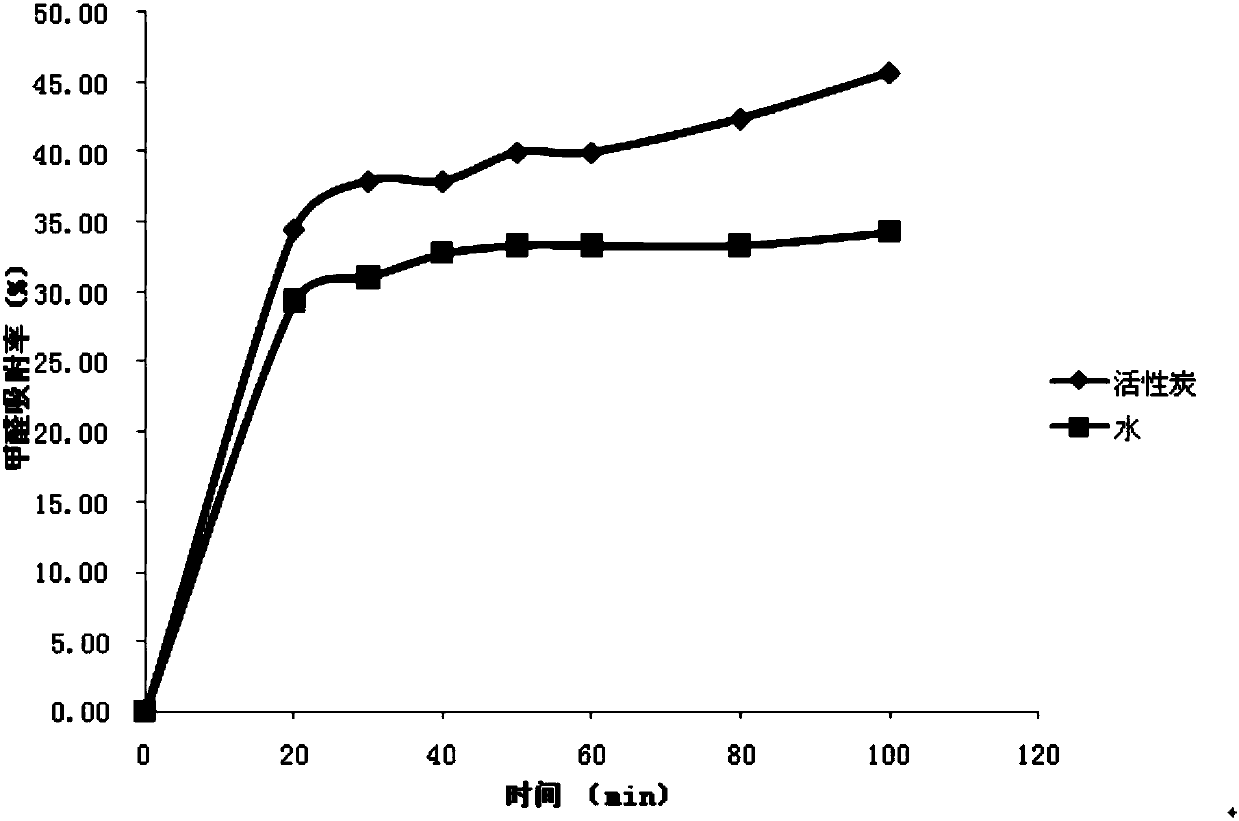

A compound and substance technology, applied in separation methods, chemical instruments and methods, and other chemical processes, can solve the problems of mold growth in rooms, shortened service life, and odor of vehicle interiors, and achieves convenient operation, low preparation cost, Strong ability to absorb moisture and formaldehyde

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

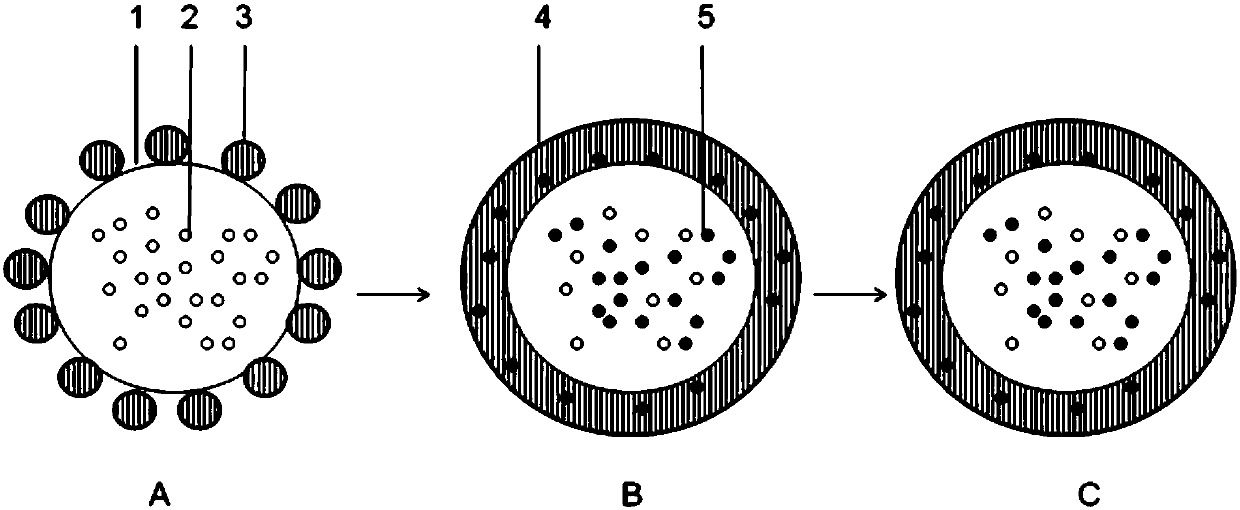

Method used

Image

Examples

Embodiment 1

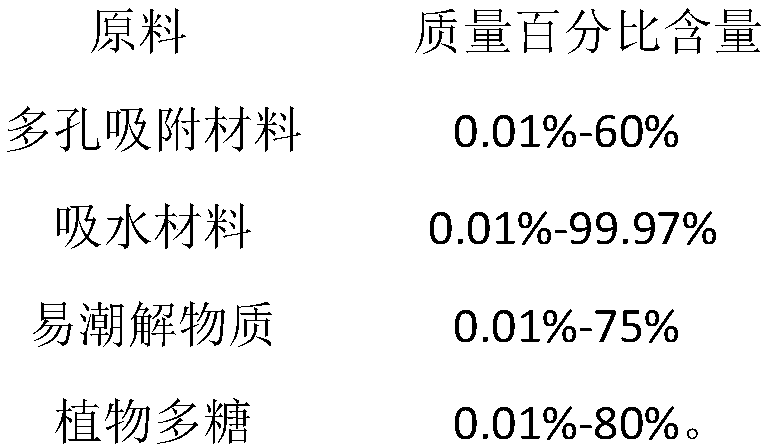

[0036] A moisture-absorbing and odor-absorbing compound prepared from the following raw materials in mass percent:

[0037]

[0038] The preparation method of above-mentioned hygroscopic and odor-absorbing compound, its steps are:

[0039] Mix wood activated carbon, konjac flour grafted sodium acrylate, zinc chloride and lignocellulose in a stirring mixer, then transfer to an extruder for extruder, at 160 ° C, 5 × 10 5 It is puffed under pa, then pulverized by a pulverizer, extruded and granulated by a sieve (20-100 mesh) to a desired size, finally sieved (the average particle size of the particles is 20-100 mesh), and packaged.

Embodiment 2

[0041] A moisture-absorbing and odor-absorbing compound prepared from the following raw materials in mass percent:

[0042]

[0043] The preparation method of above-mentioned hygroscopic and odor-absorbing compound, its steps are:

[0044] Add binding agent in shell activated carbon, as water, ethanol or the ethanol solution of the povidone of 3%-5% by mass percentage, the quality that binding agent adds is the 5% of quality of konjac flour grafted sodium acrylate, stirs evenly , to obtain wet shell activated carbon, and then spray konjac powder grafted with sodium acrylate, zinc sulfate and corn starch dextrin onto the surface of the wet shell activated carbon, then dry and solidify in a tunnel dryer, and dry at 80°C for 0.5h , finally sieved (the average particle size of the particles is 20-100 mesh), and packaged.

Embodiment 3

[0046] A moisture-absorbing and odor-absorbing compound prepared from the following raw materials in mass percent:

[0047]

[0048] The preparation method of above-mentioned hygroscopic and odor-absorbing compound, its steps are:

[0049] Wooden activated carbon, sodium polyacrylate, polyethylene glycol and tapioca starch are mixed uniformly in a mixer, then pulverized, finally sieved (the average particle size of the particles is 20-100 mesh), and packaged.

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com