Blocking-prevention dust compactor

A compactor and anti-clogging technology, which is applied in the field of dust removal equipment and dust compactors, can solve the problems of increased motor load, motor burnout, increased frictional resistance between dust and the cylinder wall, etc., to reduce grinding resistance, Improved collection efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

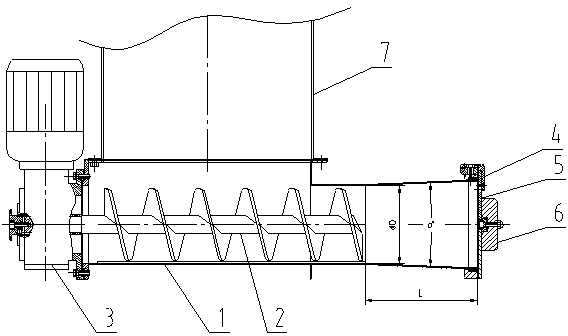

[0021] see figure 1 , the anti-clogging dust compactor of the present invention includes a housing 1, a screw shaft 2 is arranged in the housing 1, a compression reduction motor 3 is provided at the inlet end of the housing 1, and the compression reduction motor 3 The output end is connected with the screw shaft 2 , the outlet end of the housing 1 is connected with an end cover 5 through a hinge 4 , and a counterweight 6 is arranged outside the end cover 5 .

[0022] Wherein the cylinder body of the outlet section of the casing 1 is made into an inverted cone shape with a taper of 4-8°, and the ratio of the length L to the diameter D of the casing outlet section is 1-1.7.

[0023] Working principle: Since the main body 1 is equipped with a grille 2 and the accumulated materials in the dust storage hopper are overhead above the air suction port 4, the materials will not block the bottom air suction port 4, so the materials overhead above the air suction port 4 will be automatic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com