Slow-rebound polyurethane expanded foam and preparation method thereof

A polyurethane and slow rebound technology, applied in the field of polyurethane foam, can solve the problems of reduced molecular mobility, reduced comfort, and hard hand feeling of slow rebound foam, so as to reduce the glass transition temperature, improve vitality, and improve The effect of the slow rebound effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

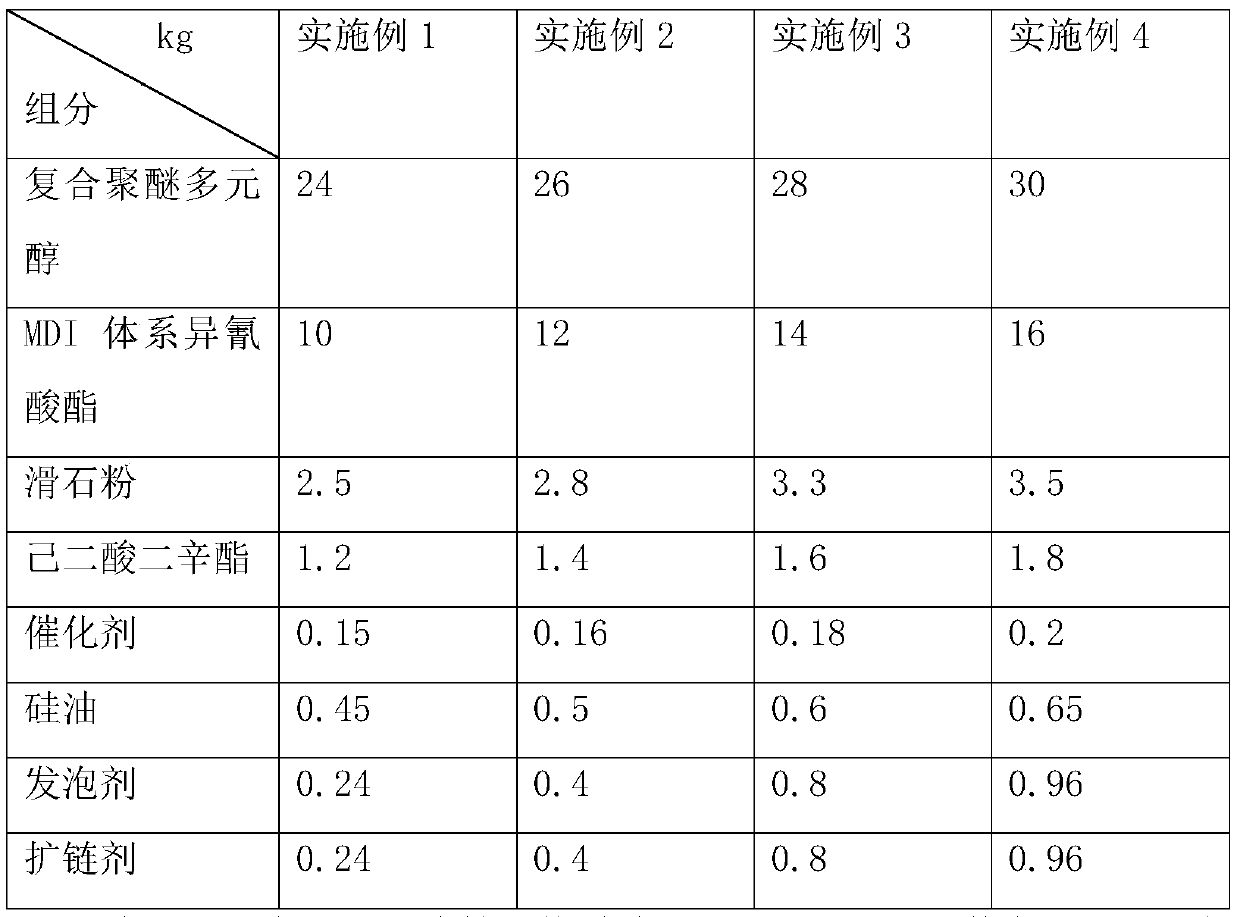

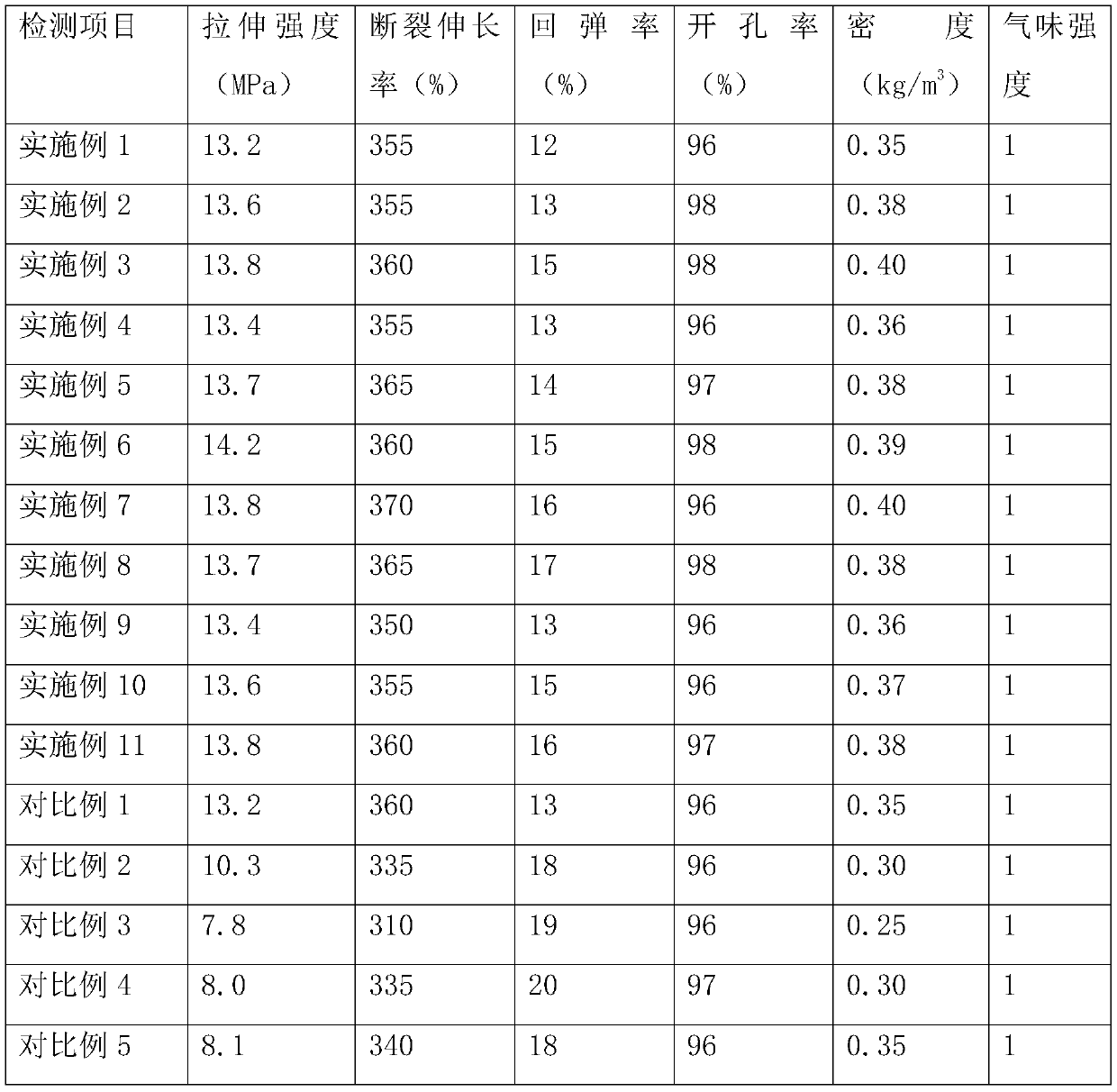

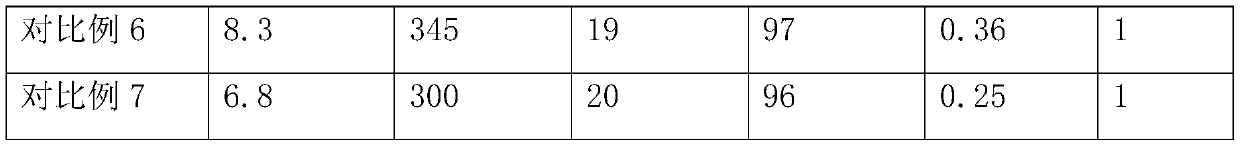

Method used

Image

Examples

preparation example 1-3

[0047] In the preparation example 1-3, the dispersant is selected from the dispersant with the article number DH-A012 sold by Guangdong Zhongbang Fine Chemical Co., Ltd., and the nano-silver powder is selected from the nanometer silver powder with the article number DK101-1 sold by Beijing Deke Daojin Technology Co., Ltd. The silver powder and nano-titanium dioxide are selected from the nano-titanium dioxide of the model P25 sold by Chongqing Kaiyin Chemical Co., Ltd., and the polyvinylpyrrolidone is selected from the polyvinylpyrrolidone with the product number PVP-K90 sold by Guangdong Yuemei Chemical Co., Ltd.

preparation example 1

[0048] Preparation example 1: (1) Cut bamboo material into slices, carbonize at 500°C for 20 days, pulverize into 100nm powder, and then carbonize at 1000°C for 5 days;

[0049] (2) by weight, 2kg nano-silver powder, 1kg nano-titanium dioxide and 0.2kg polyvinylpyrrolidone are added to 4kg dehydrated alcohol, stirred at a constant temperature at 40°C for 4h, add 4kg carbonized bamboo charcoal powder and 0.1kg dispersant, Grind for 10 minutes to obtain nanometer bamboo charcoal powder.

preparation example 2

[0050] Preparation example 2: (1) Cut bamboo material into slices, carbonize at 550°C for 15 days, pulverize into 150nm powder, and then carbonize at 1100°C for 4 days;

[0051] (2) In parts by weight, add 3kg of nano-silver powder, 1.5kg of nano-titanium dioxide and 0.3kg of polyvinylpyrrolidone into 5kg of absolute ethanol, stir at a constant temperature of 40°C for 4.5h, add 5kg of carbonized bamboo charcoal powder and 0.2kg of dispersed agent, and ground for 15 minutes to obtain nano-bamboo charcoal powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com